A waterproof repair method for a roof with a large-area steel frame structure

A large-area, planar structure technology, applied in the direction of roofing, building maintenance, roof covering, etc., can solve problems such as large roof area, difficult to find out the real source of water leakage, large building area, etc., to improve waterproof life and improve The effect of improving the service life and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Having a waterproof repair method of a large area of the roof steel structure 210, comprising the steps of:

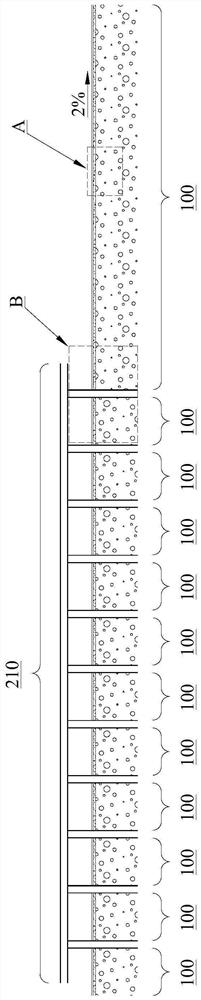

[0052] S1 analysis roof structure: the roof structure is complex, such as figure 1 , Includes at least a large number of steel structure 210 of upright 211 consisting of flat roof 100 is disposed at the level of the roof;

[0053] . S2 of the roof structure to classify: The steel structure 210 and in contact therewith a corner portion of the flat roof classified as class has a planar structure and facade structure, the flat roof classified as having a flat planar structure of the class;

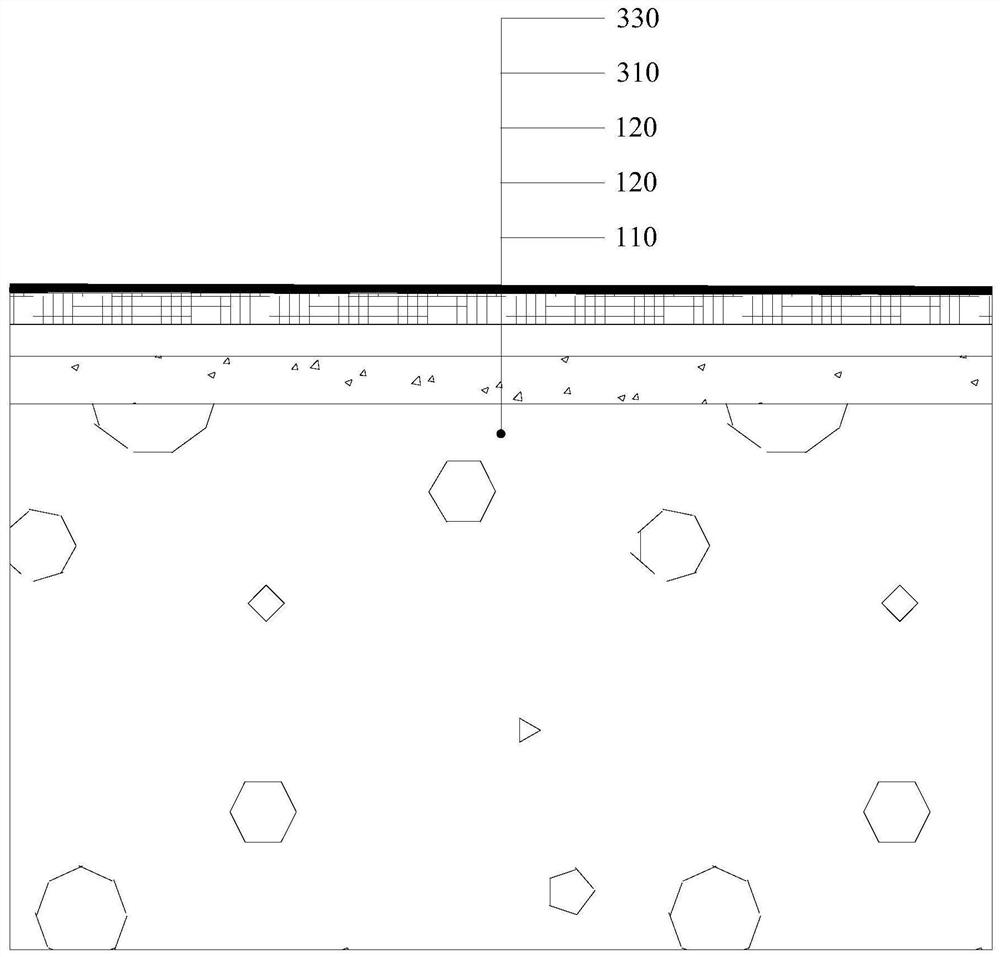

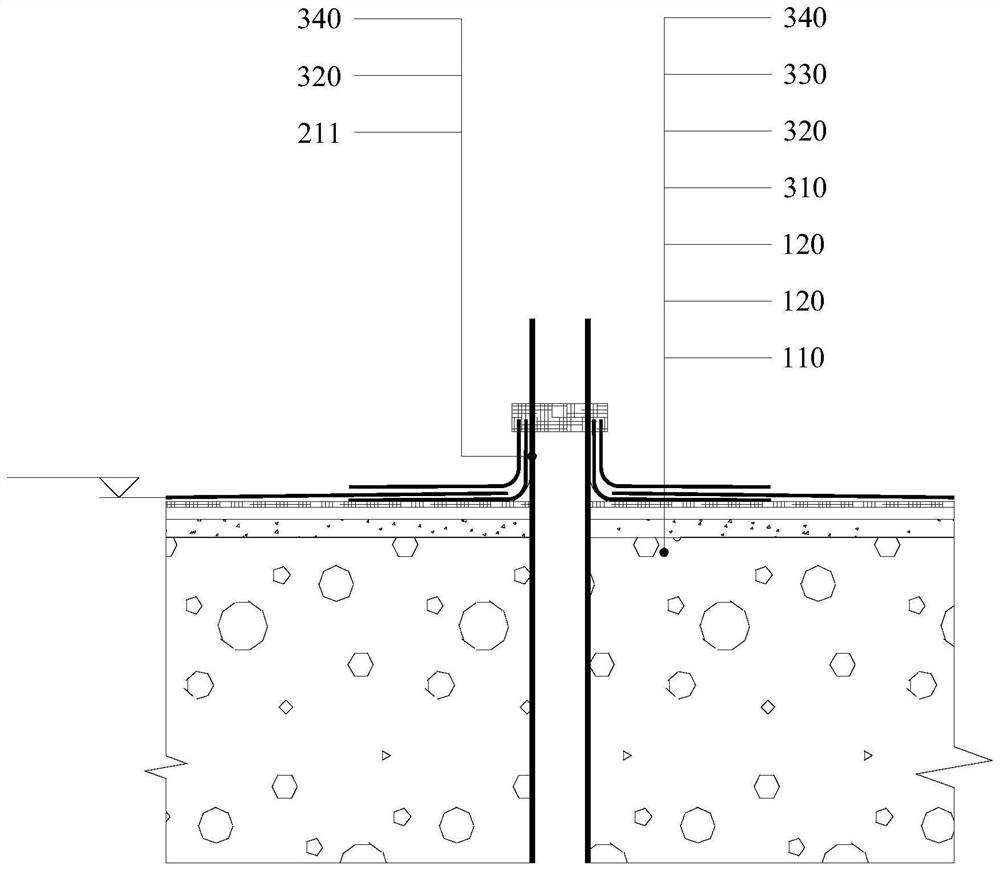

[0054] . S3 develop repair scheme: the overall roof repairs, such as figure 2 , For the first class of the plane to find the slope 310 of the first skin layer by extrusion plate laid waterproofing membrane 330, such as image 3 As shown in, for laying a double corner type is used for waterproofing repair manner, the inner layer comprising a waterproof membrane bilayer waterproofing ...

Embodiment 2

[0065] In order to further improve the reliability of water, such as image 3 As shown in this embodiment as a refinement of Example 1, except that: in the class include steel corner structure 210, the waterproofing membrane laid on the second surface 340 of post 211 extending surface laid over the flat roof, a first skin layer waterproofing membrane laid onto the flat 330 extending above the surface of a second roofing waterproofing membrane 340 is laid on the periphery of the pillar 211 above the flat roof, extruded sheet 310 is formed on a flat roof steel structure around 210 - in the first skin layer waterproofing membrane for waterproofing 320- 330- 340 at a second surface waterproofing oriented four by the superimposed structure, where a certain slope, it is possible to prevent water from the steel structure 210 a second vertical surface extending from the surface 340 waterproofing membrane laid the uppermost position, fall on the second surface of the waterproof membrane 340...

Embodiment 3

[0070] As a refinement of this embodiment, the above-described embodiment, except that: The Figure 5 As shown in step S1, the roof further comprises a roof laid flat in the patio 220, classified as a corner step S2 class 220 and further comprising a patio flat roof portion in contact therewith, such as Figure 6 ~ 8 , In the category include patio corner 220 waterproofing membrane is laid in layer 320 before contact with the flat roof and patio 220 pairs of flat roof surface excavation structural layer until the leakage level is reached so that the flat roof of the roof when a gap is formed between the surface 430 and 220 patio, laying the inner layer waterproofing membrane for waterproofing layer 320 in the intermediate portion 320 is press-fitted in the slit 430, i.e., the inner layer in the laying of the waterproofing membrane 320 in waterproofing membrane layer both ends of the sheet 320 are laid on the flat roof and facade patio 220 and leaving between the flat roof and facade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com