Steel assemblage clamping device

A clamping device and assembly technology, which is applied in the field of auxiliary equipment for section steel production, can solve problems such as cumbersome positioning operations and inconvenient welding, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

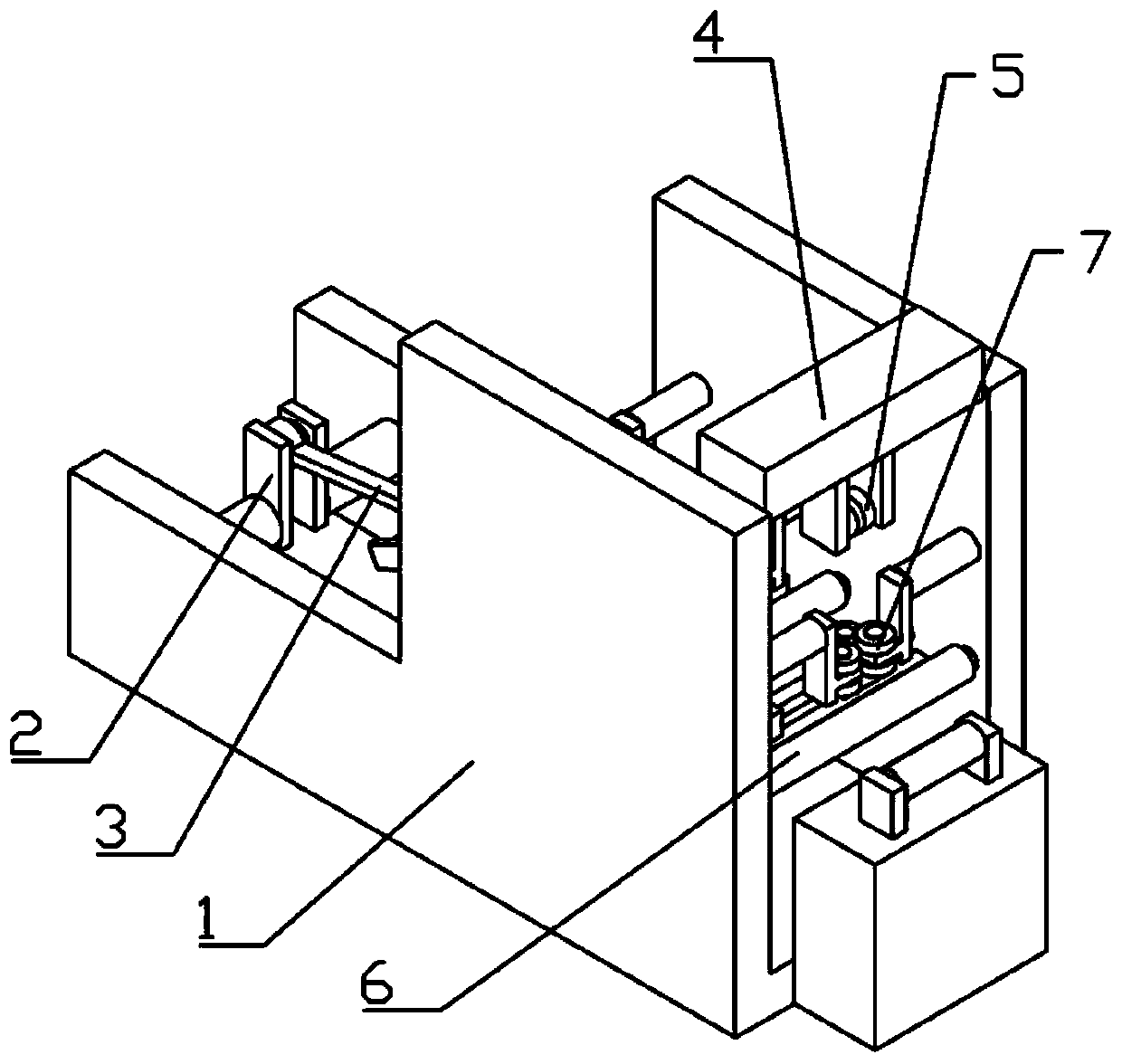

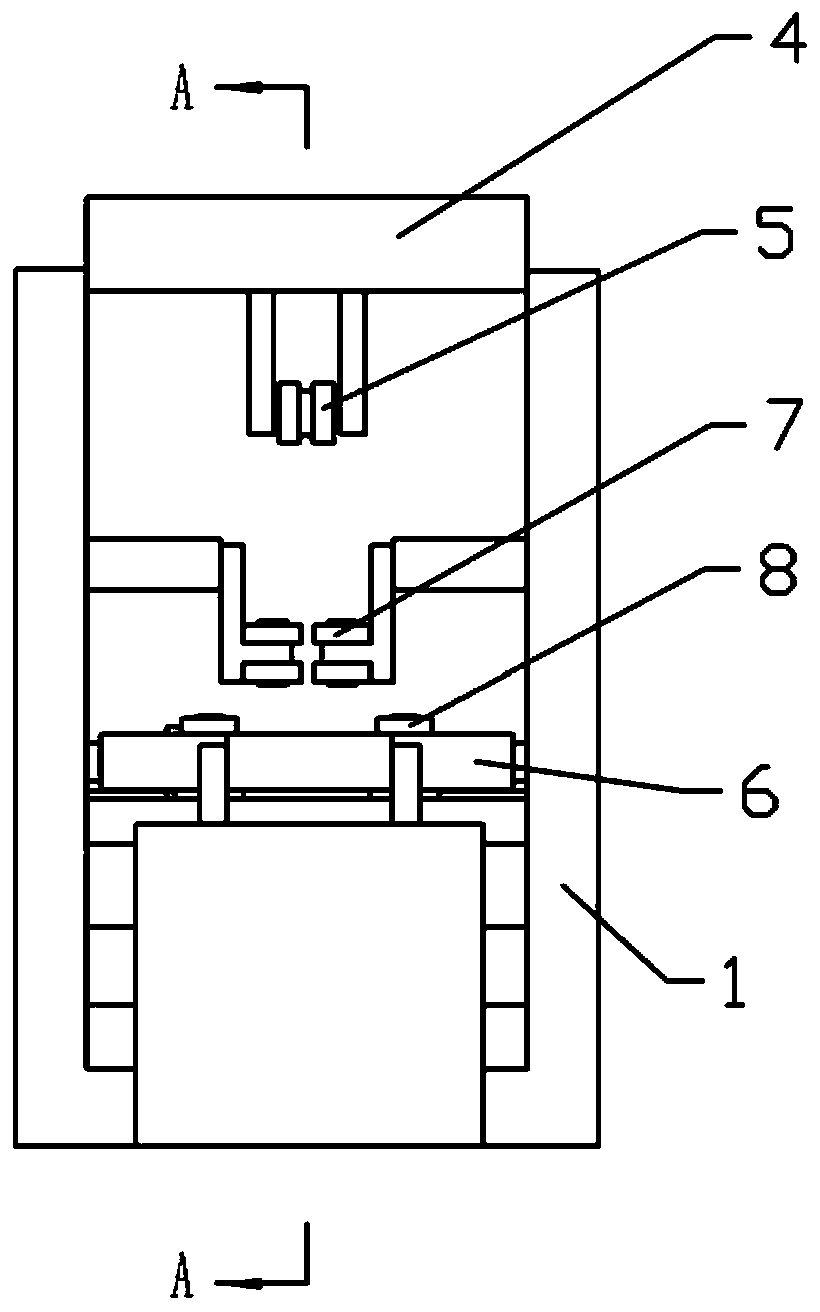

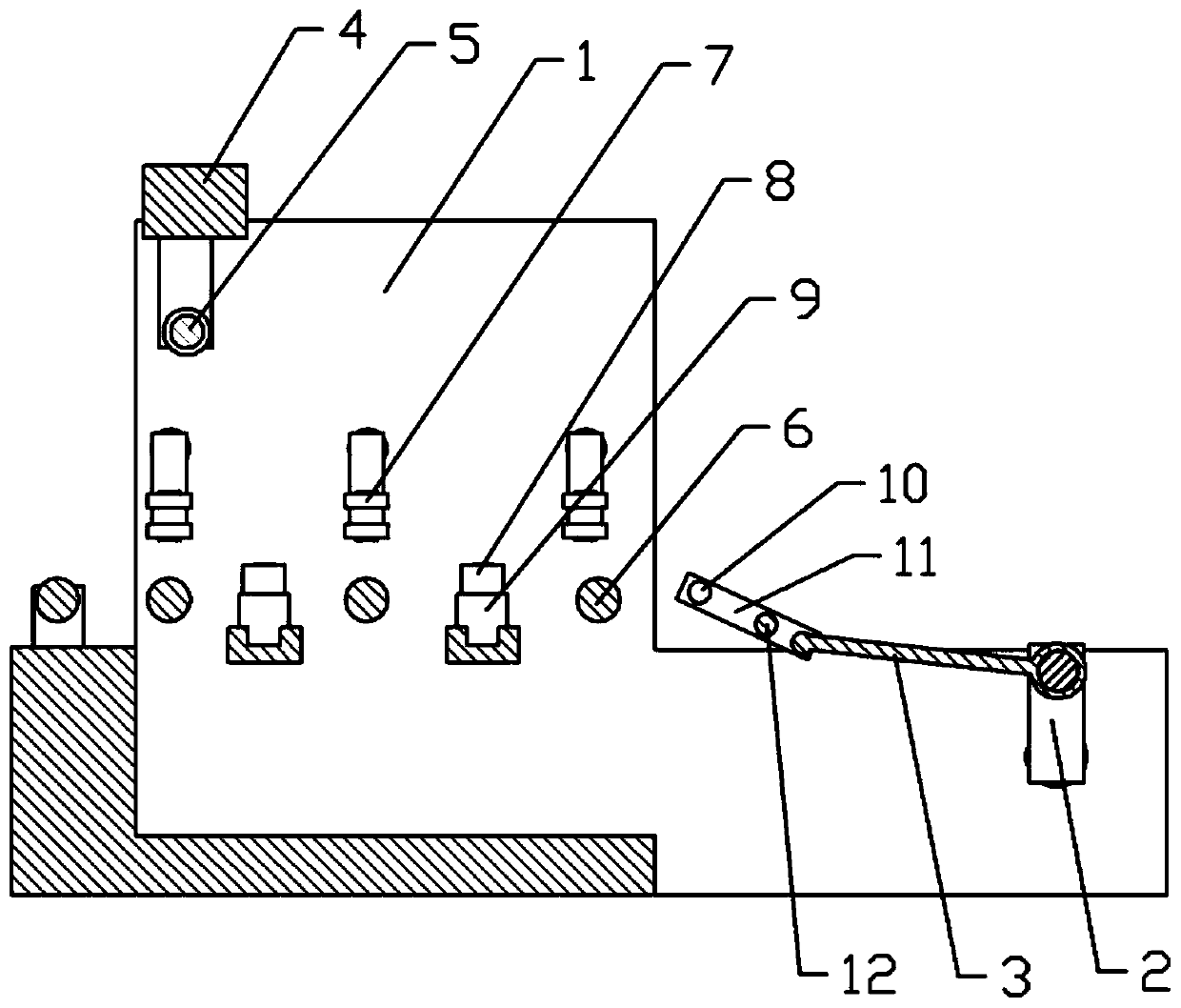

[0023] Embodiment one: if Figure 1 to Figure 5 As shown: a vertical clamping device for a steel group, including a bracket 1, on which three supporting rollers 6 arranged horizontally are rotatably connected, and the three supporting rollers 6 are horizontally arranged side by side; the gap between adjacent supporting rollers 6 is provided with a first 8 sets of positioning wheels, the first 8 sets of positioning wheels include two first sliders 9 arranged in gaps, and the two first sliders 9 are slidably connected with the bracket 1 along the axial direction of the support roller 6, and the two first sliders 9 are The sides away from each other are rotatably connected with screw rods, the axial direction of the screw rods is parallel to the axial direction of the support roller 6, and the end of the screw rods away from the first slider 9 is threadedly connected with the support 1; the two first sliders 9 are rotatably connected There is a first positioning wheel 8 whose axi...

Embodiment 2

[0027] Embodiment 2: The difference from Embodiment 1 is only that a torsion spring is provided at the hinge between the clamping frame 11 and the connecting rod 3, and the clamping frame 11 makes the upper nip roller 10 always have the principle under the action of the torsion spring. The trend of the connecting rod 3; the upper nip roller 10 and the clamping frame 11 are connected by a one-way bearing, and the upper nip roller 10 can only rotate counterclockwise under the action of the one-way bearing, so that the connecting rod 3 can push the clamp When the holder 11 moves, it is convenient for the upper nip roller 10 to pass over the welding spot 15, and when the pull rod pulls the gripper 11, the upper nip roller 10 cannot rotate, which is beneficial to increase the effect between the upper nip roller 10 and the welding spot 15 force, to ensure that the clamping part drives the wing plate 14 and the web plate 13 to move through the welding spot 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com