High-reliability and high-efficiency multi-Z-pin pressing-in and cutting-off mechanism

A cutting mechanism and z-pin technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of poor implant accuracy, low reliability, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

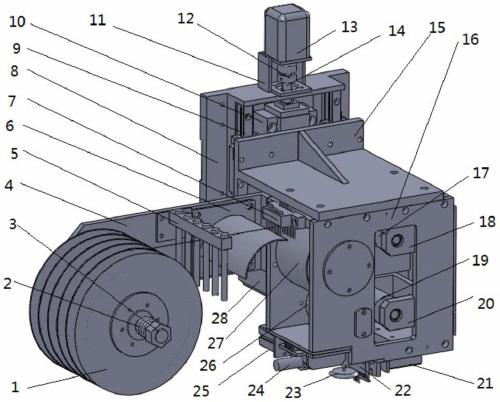

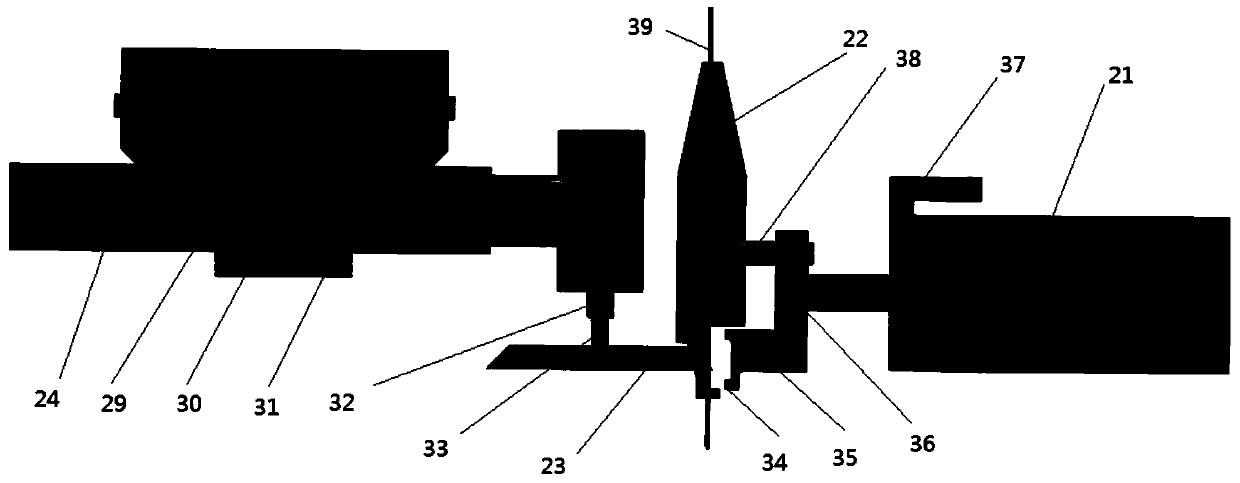

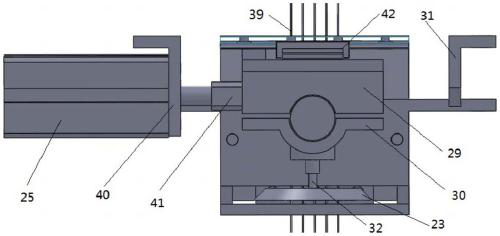

[0006] exist figure 1 and figure 2 Among them, the feeding mechanism includes a feeding tray (1), a compression spring (2), a lock nut (3), a feeding seat plate (4), a thread separating comb (5), a transition plate (6), and a positioning comb ( 7) The upper top roller (17) and the upper top roller seat (18) are supported; the press-in motor (13) drives the screw (14) to rotate through the coupling (12) to realize the vertical movement of the sliding table seat (15) Reciprocating feed movement, and precise control of feed displacement; slide table seat (15) is connected with box body (16).

[0007] The pressing and cutting mechanism is installed at the bottom of the casing (16).

[0008] exist figure 1 and figure 2 In the embodiment, the Z-pin (39) in the discharge tray (1) is manually stretched out, and the positioning comb (7 ) and pass through the corresponding interval, and then pass between the upper top roller (17) and the guide roller (27), between the lower top r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com