Rear oil cap molding technology and drilling tool used in technology

A forming process and oil cap technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing the production cost of the rear oil cap, reducing the production efficiency of the rear oil cap, and the high cost of the oil plug seat. Achieve the effect of reducing the possibility of leakage, reducing production costs and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A rear oil cover forming process, comprising the steps of:

[0035] S1, blanking: the whole original plate is cut into a plurality of rectangular blocks by a shearing machine, the size of any one of the blocks is sufficient to complete the forming of the rear oil cap, and the original plate is made of a Q235A steel with good toughness, plasticity and hot workability;

[0036] S2. Blanking: the block material is punched into a circular workpiece that is convenient for forming the rear oil cover through a punching machine, thereby avoiding the sharp corner cracking and poor material flow of non-circular workpieces in the subsequent drawing process. In case of uneven material flow;

[0037] S3, drawing: coating the inner and outer sides of the circular workpiece with drawing oil, and then drawing the circular workpiece coated with drawing oil into the shape of the rear oil cover through a hydraulic press, The coating of drawing oil can not only ensure the surface process...

Embodiment 2

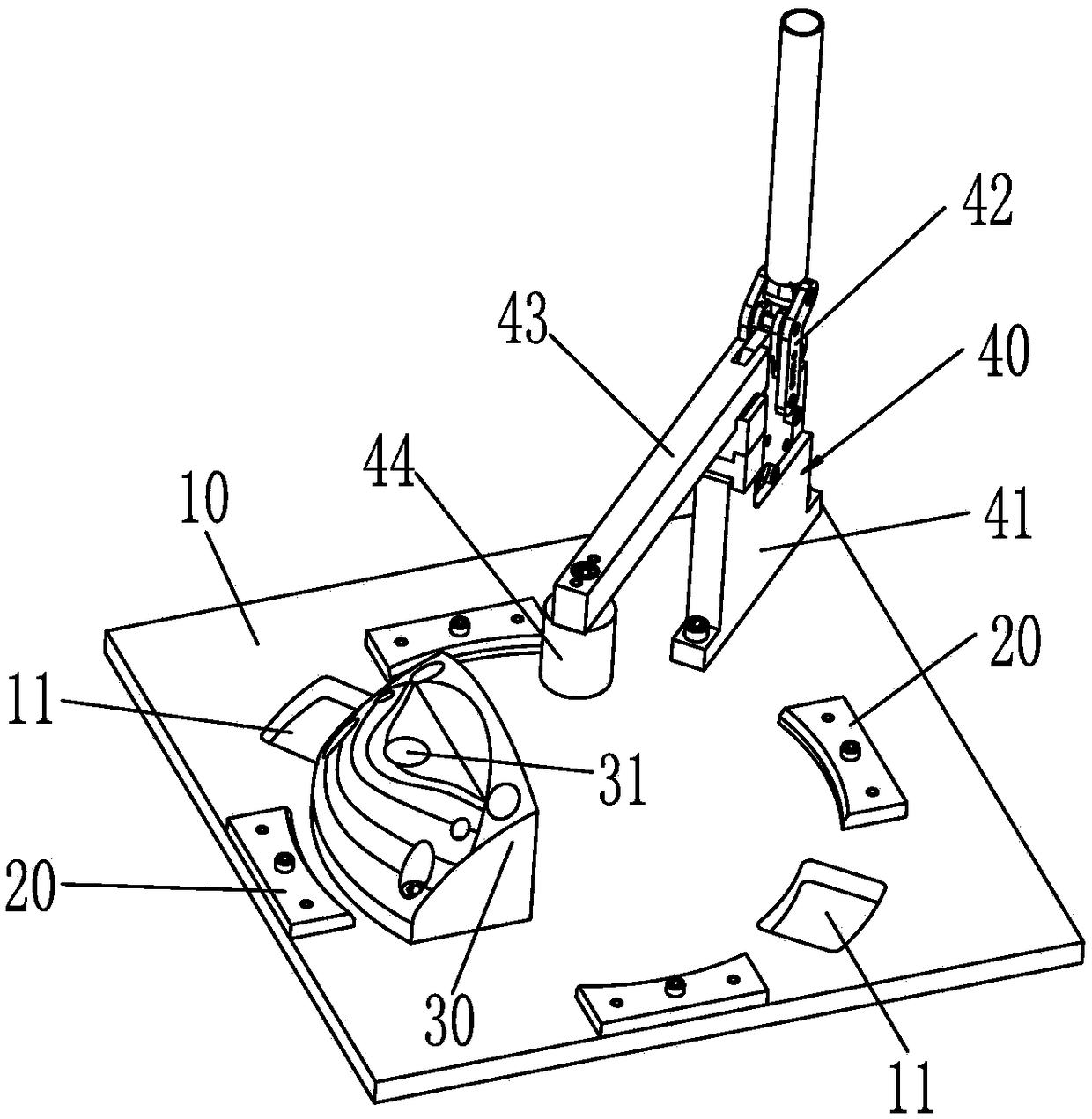

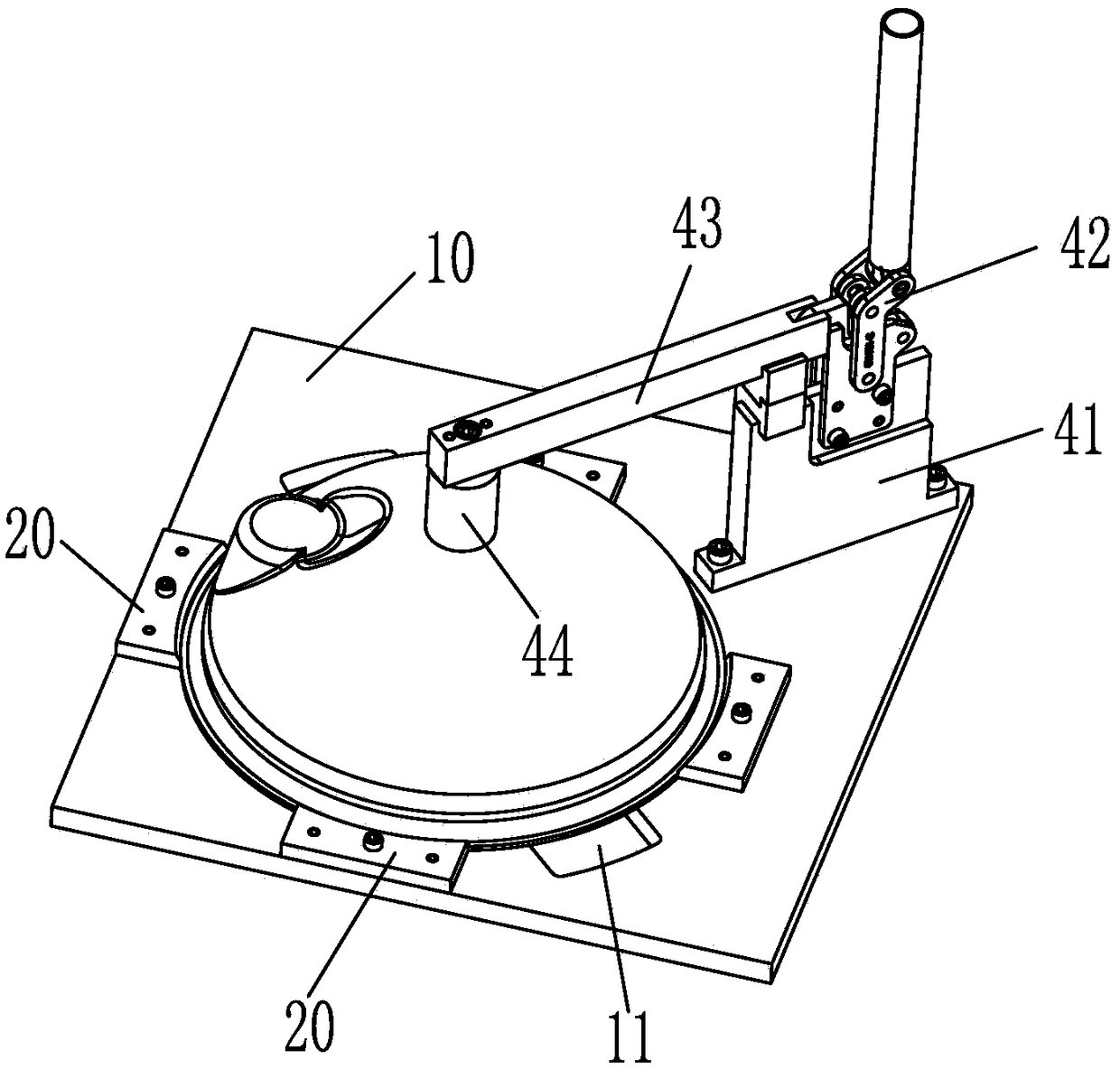

[0044] The drilling tool used in the described a kind of rear oil cap forming process, such as figure 1 , 2 As shown, it includes a base 10 fixed on the drilling machine workbench. The upper surface of the base 10 is fixed with four positioning plates 20 by bolts. The four positioning plates 20 are distributed along the circumferential direction, and the four positioning plates 20 are distributed along the circumferential direction. The area between the positioning plates 20 constitutes the placement area of the rear oil cover; the placement area of the rear oil cover on the base 10 is fixed with a support positioning block 30 by screws, and the upper surface of the support positioning block 30 is in contact with the rear oil cover. The inner surface of the hole to be drilled coincides, the setting position of the support positioning block 30 in the placement area of the rear oil cover corresponds to the setting position of the rear oil cover to be drilled in the rear oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com