High-precision textile equipment

A kind of textile equipment and high-precision technology, which is applied in the textile field, can solve the problems of easy deviation of cloth and lower printing precision, and achieve the effect of improving cutting precision, improving precision, and improving cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

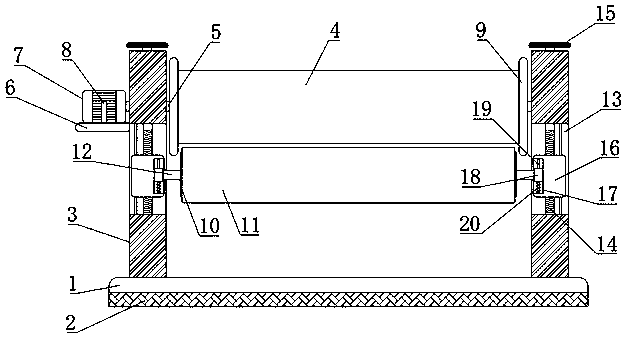

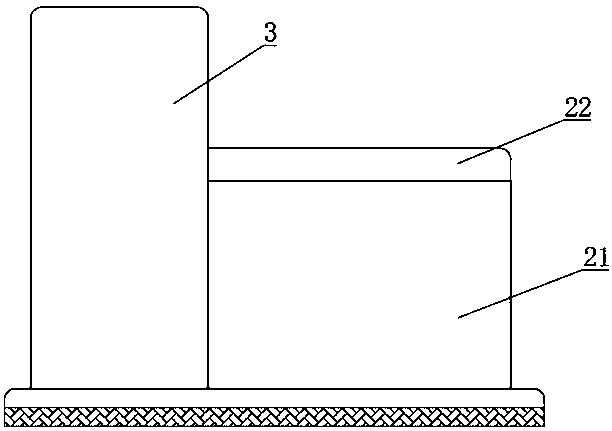

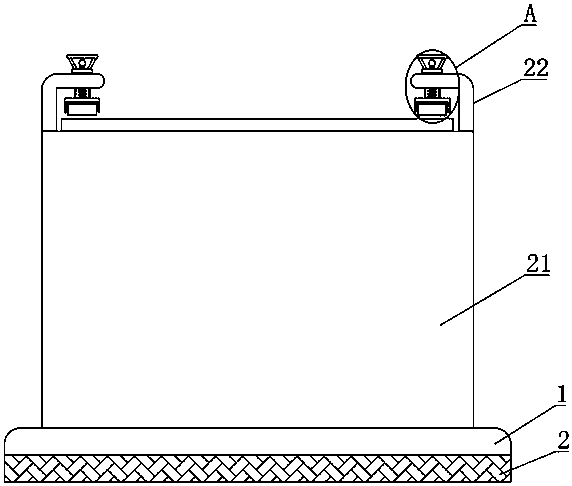

[0027] refer to Figure 1-4 , a high-precision textile equipment, including a base 1, the bottom end of the base 1 is fixedly connected with a shock absorber 2 by bolts, the lower end of the shock absorber 2 is provided with anti-skid lines, and the shock absorber 2 reduces the time when the equipment on the base 1 is working. The vibration is sent out, so that the equipment can maintain stable operation, thereby indirectly improving the accuracy of the equipment. The upper end of the base 1 is symmetrically fixedly connected with two support plates 3, and the upper end between the two support plates 3 is provided with a rotating roller 4, and the rotating roller 4 Rotating shafts 5 are fixedly connected to both ends of the two rotating shafts 5, and the other ends of the two rotating shafts 5 are inserted into the inside of the support plate 3, and the other end of one of the rotating shafts 5 passes through the support plate 3 and is connected with the drive mechanism.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com