Clamp for processing double-head piston ball pit

A double-headed piston and ball pit technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of poor positioning effect, easy damage to the embryo body, loose embryo body, etc. The effect of firm and accurate radial positioning and firm and accurate radial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

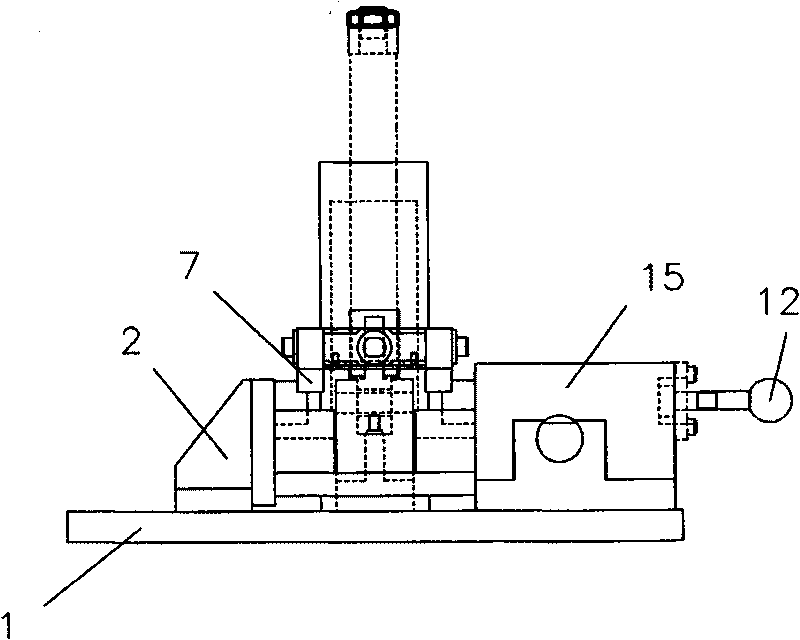

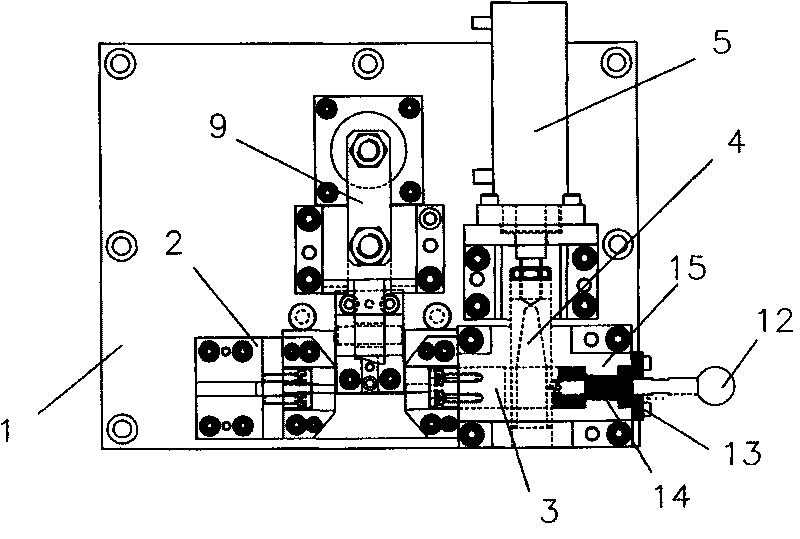

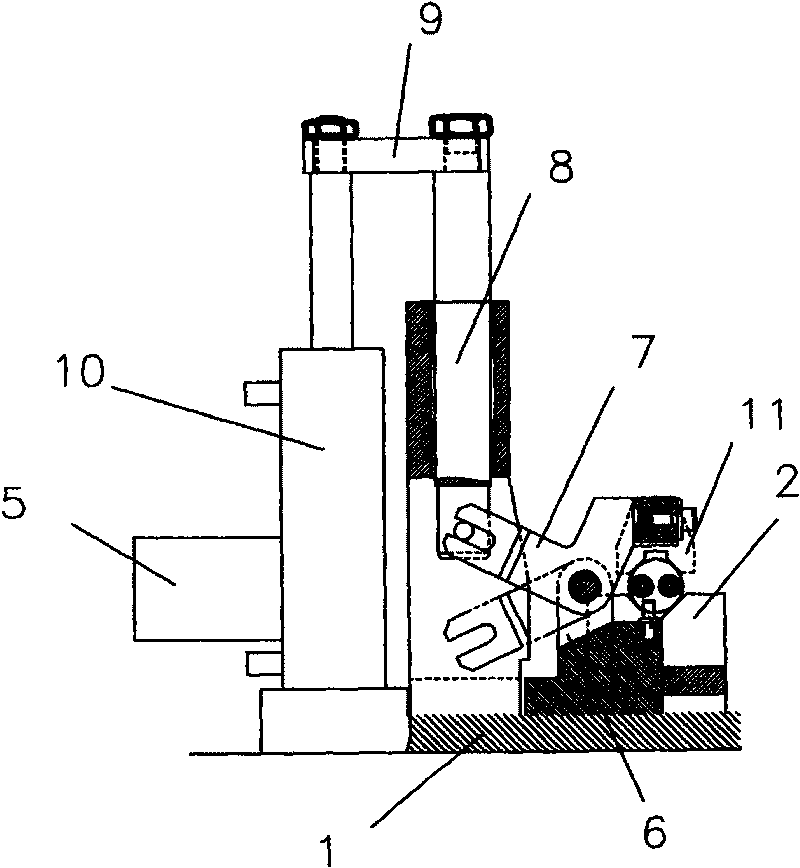

[0015] Such as figure 1 As shown, the fixture used for the processing of the double-headed piston ball pit described in this embodiment mainly includes a base plate 1 on which a positioning block 2 and a positioning block 2 are provided in the top tightening rod seat 15 to cooperate with the positioning block 2. The jacking rod 3 is provided with a telescopic pinning rod 4 on the side of the jacking rod 3, and the pinning rod 4 is connected with the first hydraulic cylinder 5 in transmission, and the bottom plate 1 is also provided with a pressing arm 7, and the pressing arm 7 A pressing arm 7 is arranged on the top, and the pressing arm 7 is installed on the pressing arm seat 6 through a hinge structure, and one end thereof is located above the positioning block 2 and is clamped with the positioning block 2 . The pinning rod 4 can play a good locking effect on the jacking rod 3. When the jacking rod 3 is positioned to press the workpiece, the pinning rod 4 can be operated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com