Laser welding head

A technology of laser welding and working head, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve difficult, cumbersome and other problems, and achieve the effect of good pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

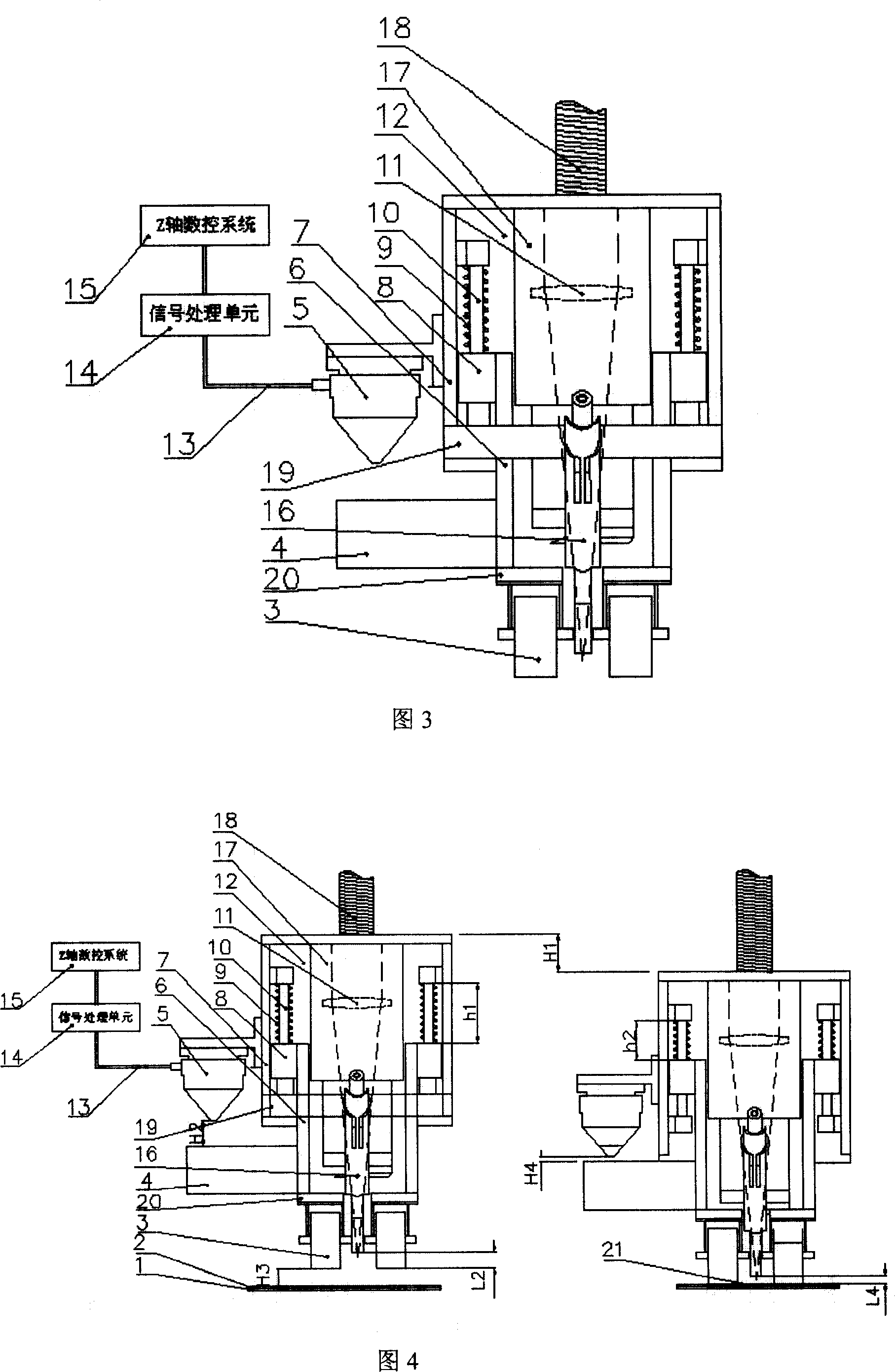

Embodiment 1

[0028] The schematic diagram of the structure of Embodiment 1 of the present invention is shown in Figure 3. The welding head includes a welding nozzle 16, a welding head 17, a frame plate 12, a static support plate 7, a dynamic support plate 6, a guide rail 10, a spring 9, and a slider 8 , pressing part 3, height tracking sensor 5, height tracking reference surface 4, signal processing unit 14, Z-axis control system; wherein: welding head 17 is installed on the frame plate 12, and its axis coincides with the laser transmission axis, and the frame The plate 12 is connected with the Z-axis transmission shaft 18, the static support plate 7 is distributed on both sides of the welding head 17, and is installed on the frame plate 12, the guide rail 10 is installed on the inner side of the static support plate, the spring 9 is installed on the guide rail 10, and the slider 8 is installed on the bottom of the guide rail 10, the spring 9 is set on the outer circumference of the guide r...

Embodiment 2

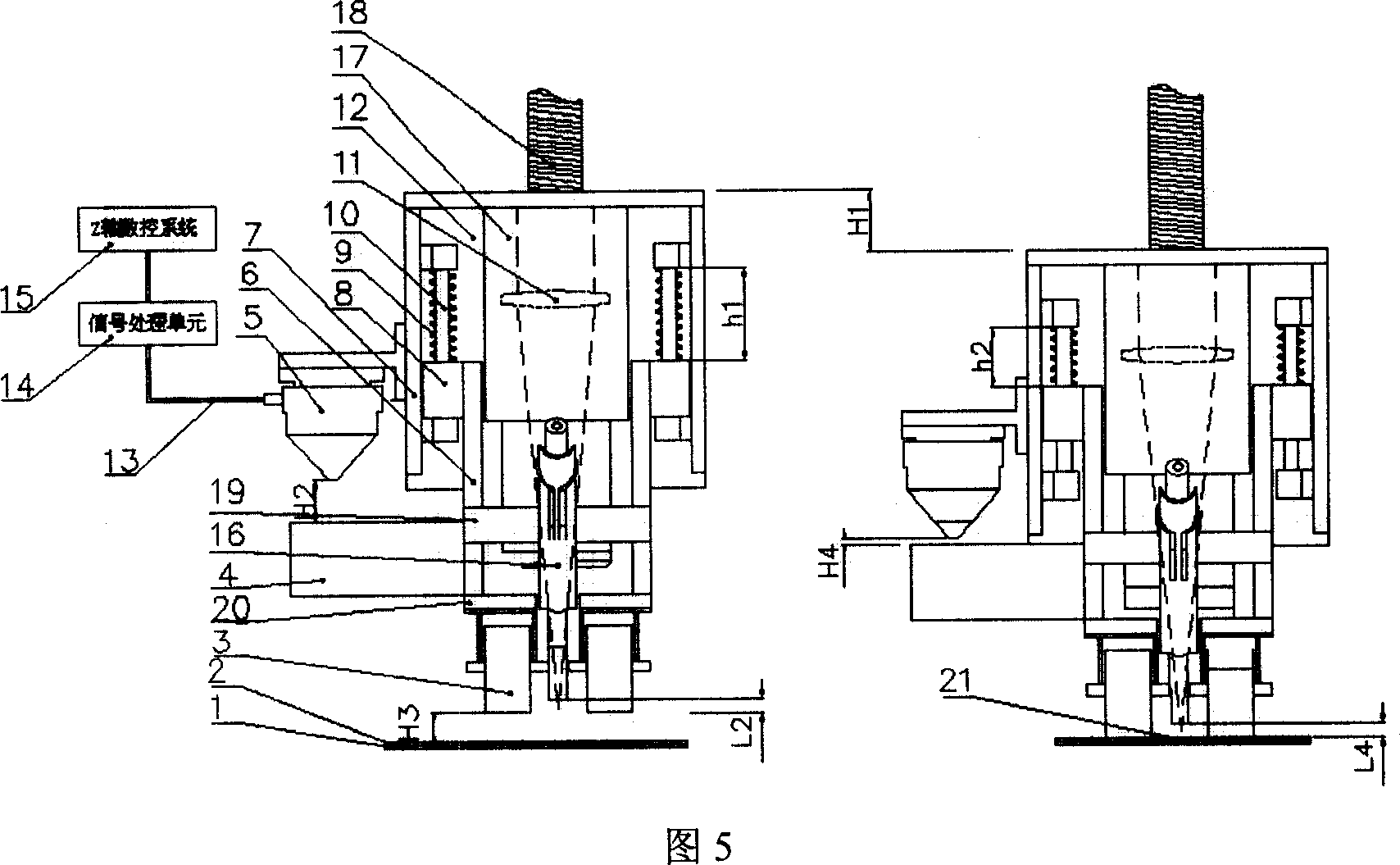

[0037] Referring to FIG. 3 for Embodiment 2 of the present invention, the structure of Embodiment 2 is the same as that of Embodiment 1, except that the welding nozzle support plate 19 is installed on the movable support plate 6 . Its working principle diagram is shown in Figure 5. Since the welding nozzle support plate 19 is installed on the movable support plate 6, the relative position of the welding nozzle 16 and the bottom surface of the pressing part 3 remains unchanged, that is, L2=L4, which can also reflect H3 has nothing to do with the topographic features of the welded workpiece. Since the height tracking sensor 5 can ensure that the bottom of the pressing part 3 is always on the surface of the upper workpiece 2 during the welding process, it is guaranteed that the welding nozzle 16 is always constant relative to the surface of the upper workpiece 2 during the welding process, thereby ensuring that the welding head While maintaining a constant pressing force on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com