J-shaped wire clamp operating member

A technology for operating parts and wire clips, applied in the field of J-type wire clip operating parts, can solve the problems of high installation process risk and dangerous staff, and achieve the effects of wide application range, high fixing stability and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

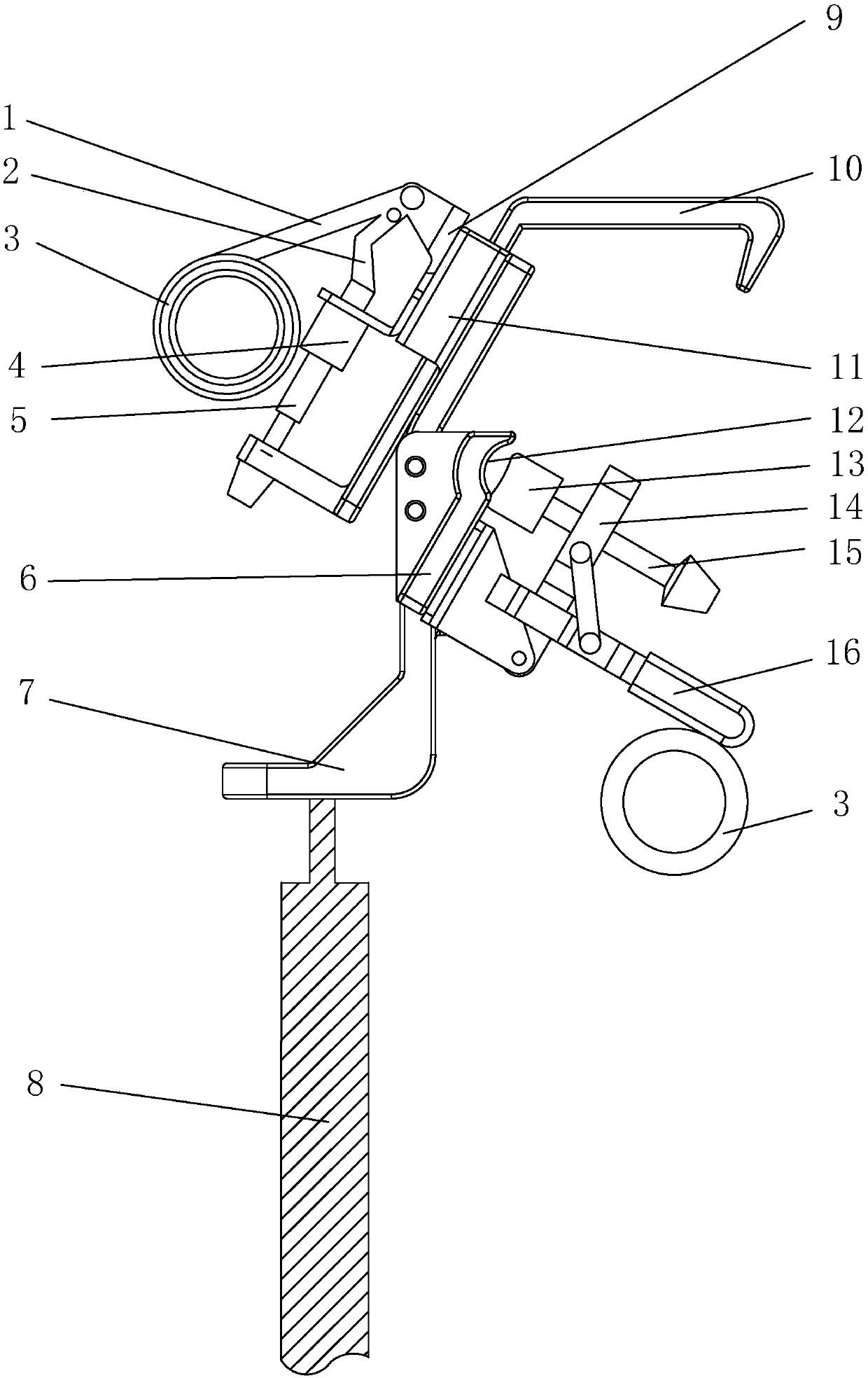

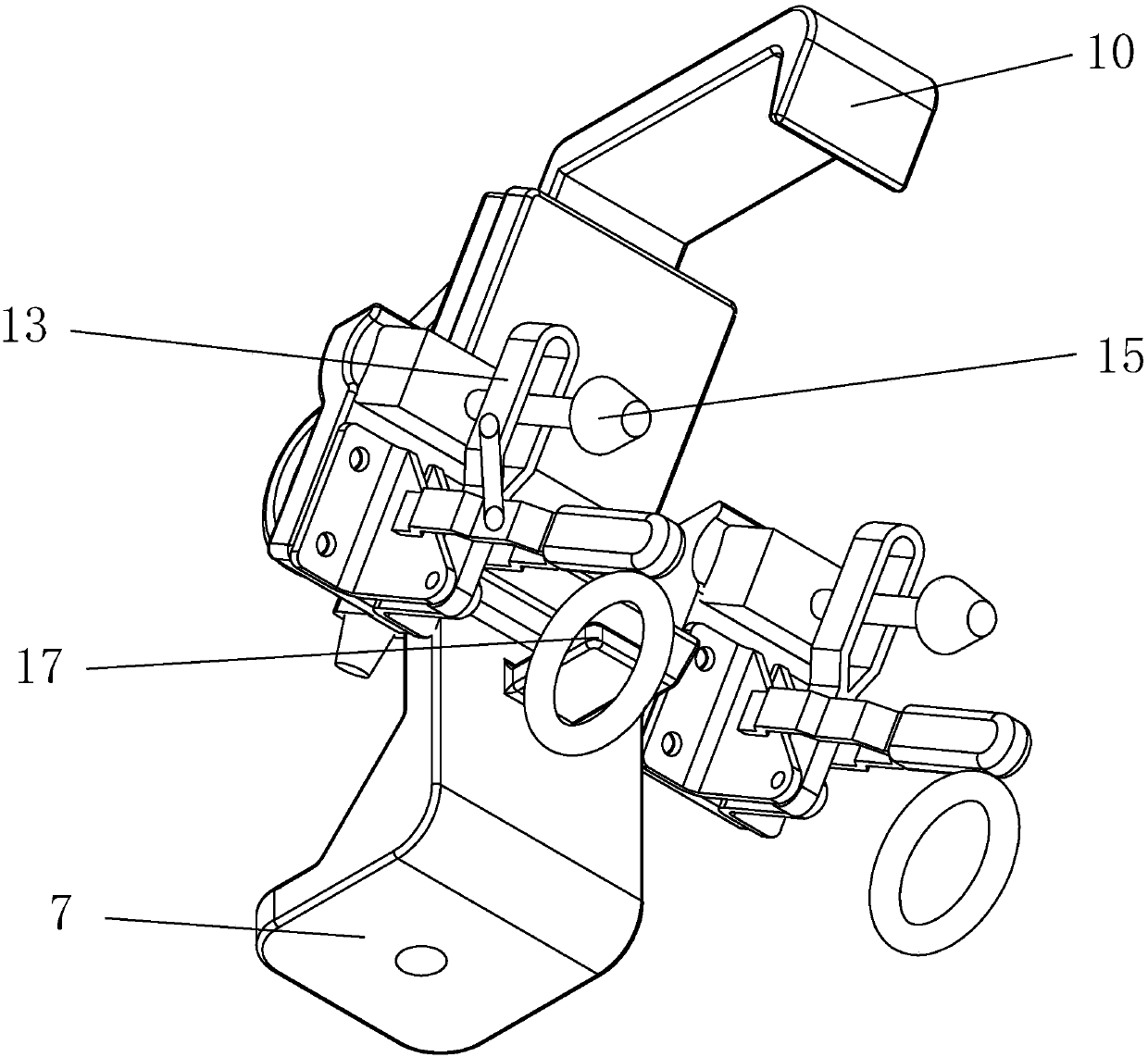

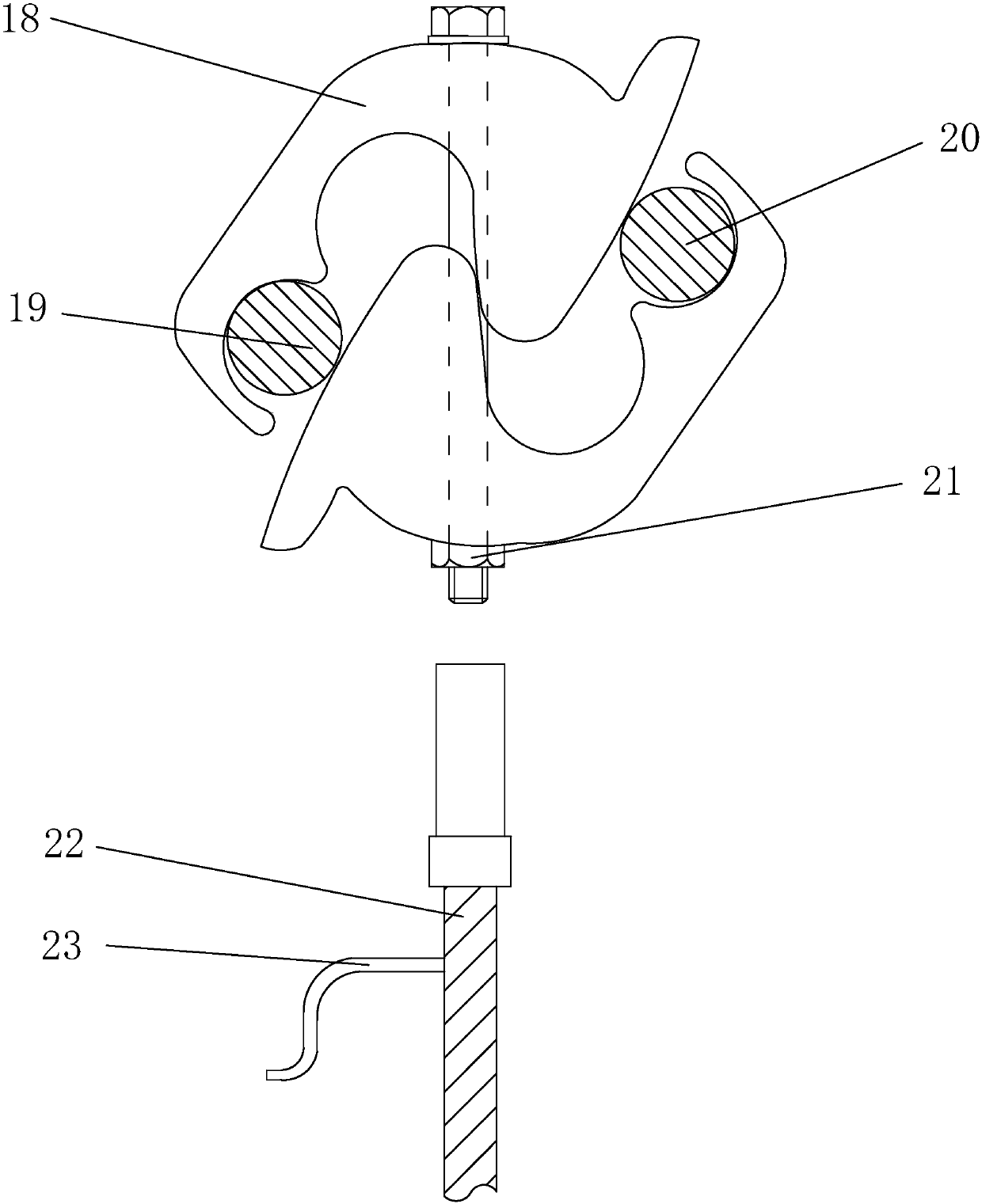

[0018] Embodiment 1: as figure 1 , 2 As shown in , 3, a J-shaped wire clip operating part includes a main body 7, a sleeve operating rod 22 and a support rod 8 arranged below the main body. The support rod and the main body are threadedly connected, and the connection is stable, and the disassembly is also very convenient. The support rod is made of insulating material, which will not conduct electricity when in use, which increases safety. During operation, the operator can stand on the ground and carry out a series of operations with the support rod in hand. The support rod supports the entire device. The main body is equipped with a cable Clamp clamping mechanism, the wire clamp clamping mechanism includes a guide block 11 fixed on the main body, a fixed seat 9 fixed on the guide block, a guide rod 1 hinged with the fixed seat, a connecting arm 2 hinged with the guide rod, and a connecting arm 2 The guide post 5 connected to the arm, the clamping part 10 fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com