High-speed hydrodynamic machine and composition method and assembly method of rotor of high-speed hydrodynamic machine

A high-speed fluid and power machinery technology, which is applied to the components of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc. The process is simple, the transmission efficiency is improved, and the sealing effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

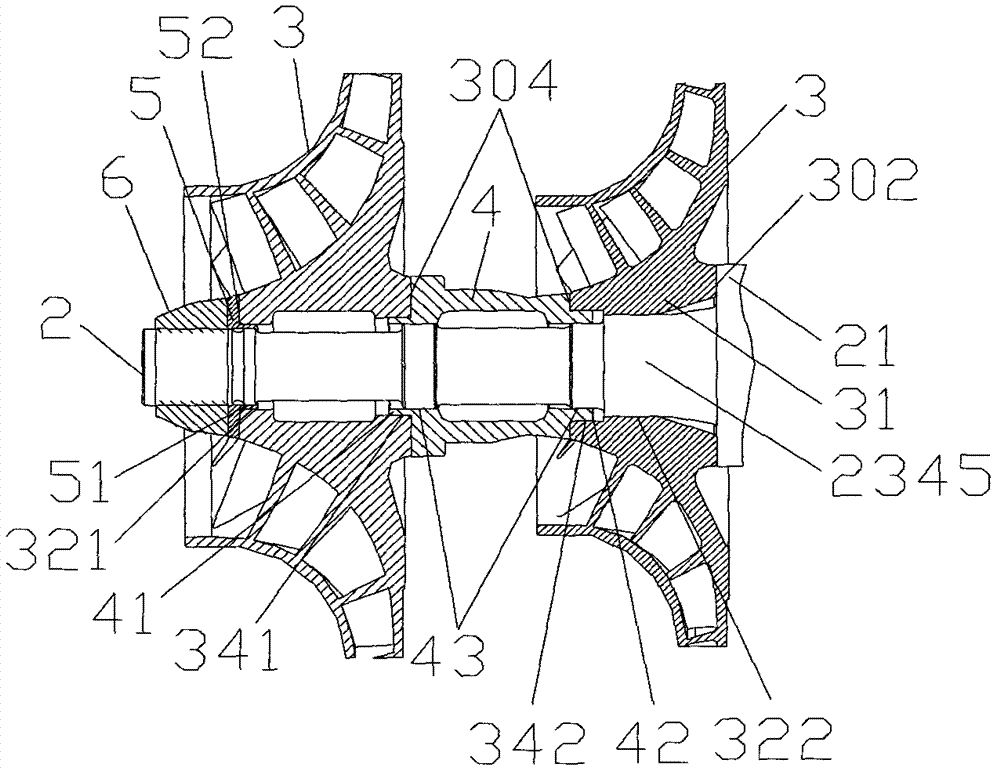

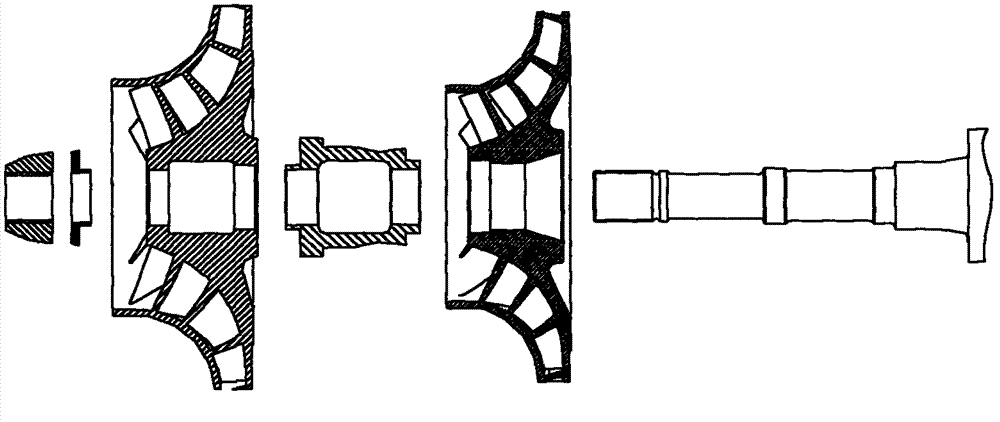

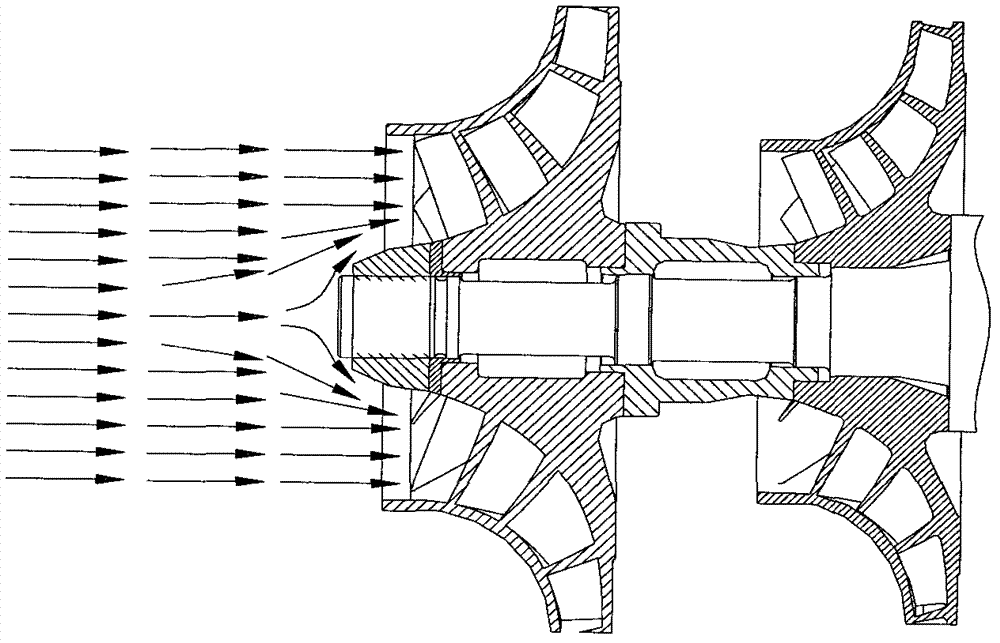

[0064] The advantage of the present invention is that it is suitable for high-speed fluid power machinery, especially high-speed centrifugal compressors with a speed above 6000 rpm, such as a high-speed centrifugal compressor with a speed of 7000 rpm to 20000 rpm. In this embodiment, the high-speed centrifugal compressor using R134a as the working medium is used as In a preferred embodiment, the working fluid can better adapt to the working range of the refrigeration centrifugal compressor at this speed. On the one hand, high-speed fluid power machinery with such a rotating speed should consider the high transmission efficiency, and on the other hand, the installation of the impeller 3 and the rotating shaft 2 should have high firmness and safety, especially to ensure that the impeller 3 and the rotating shaft 2 To maintain a high coaxiality during high-speed rotation, it is also necessary to consider easy assembly and low process cost. Taking these factors into consideration, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com