Tilting-pad sliding bearing nozzle with elastic thermal oil partition devices

A technology for sliding bearings and hot oil, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problem of increasing the amount of lubricating oil, and achieve the effects of reducing oil inlet temperature, ensuring stability, and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means and features realized by the present invention easy to understand, the present invention will be described below in conjunction with the accompanying drawings.

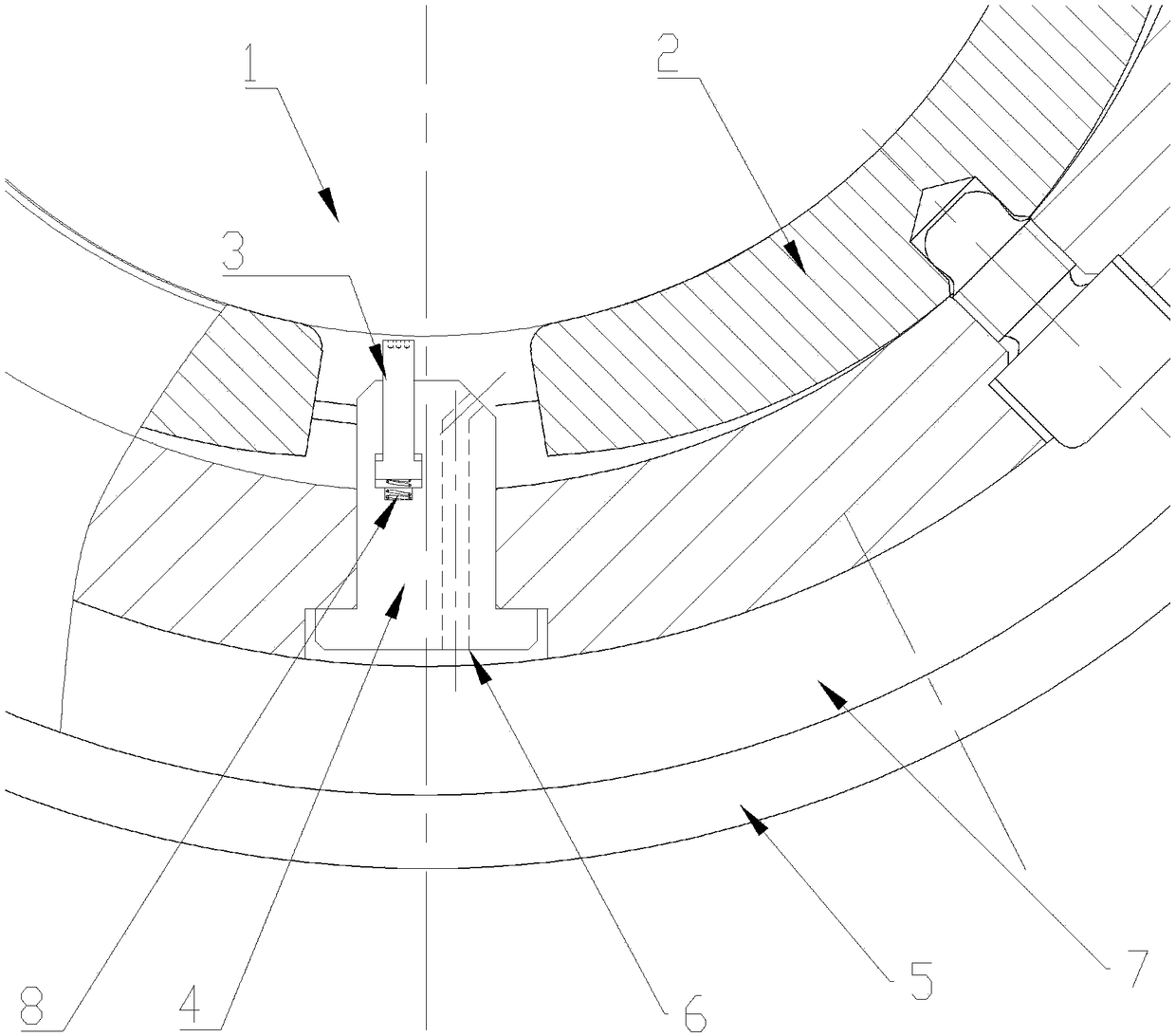

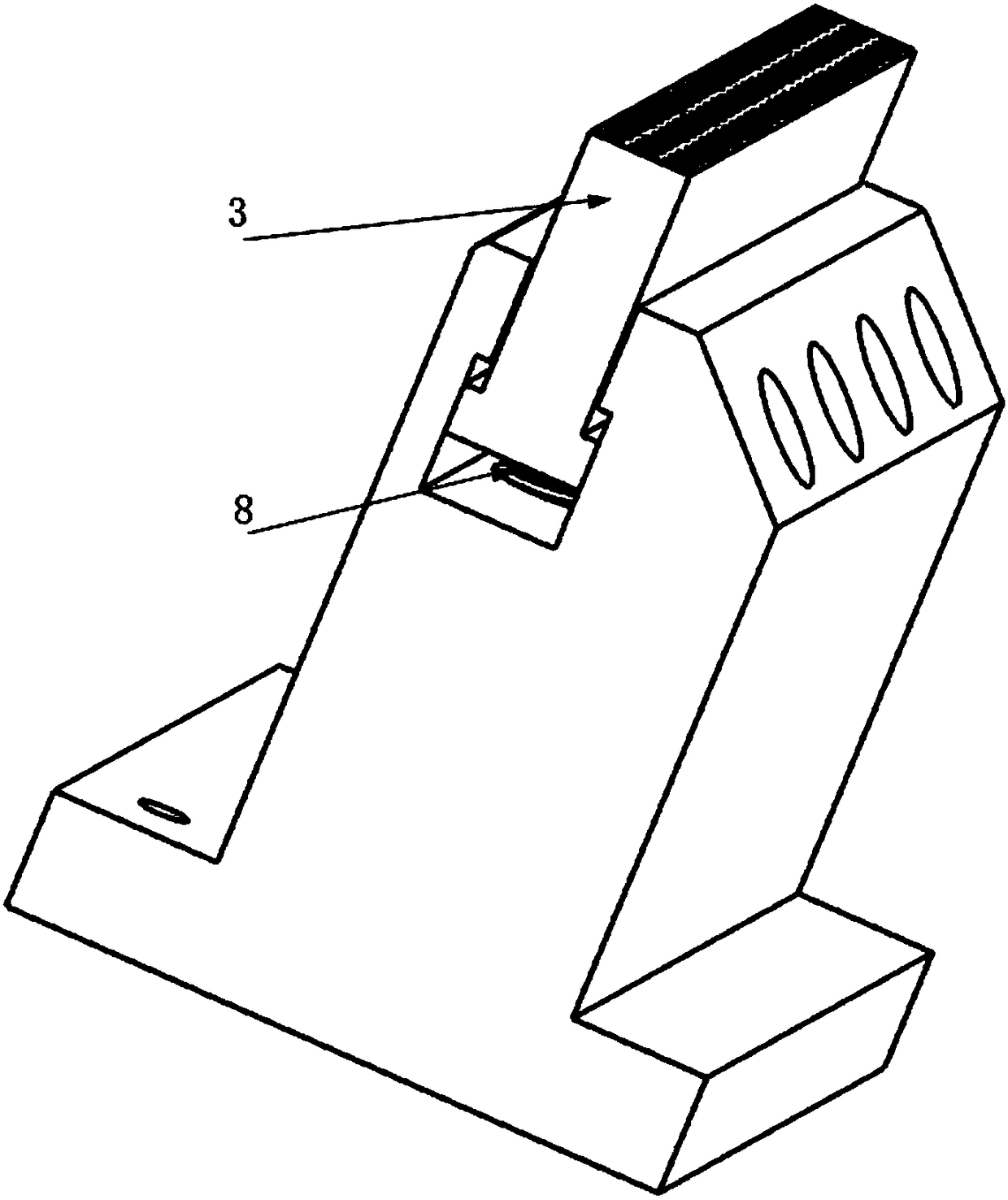

[0032] Such as Figure 1-Figure 2 shown;

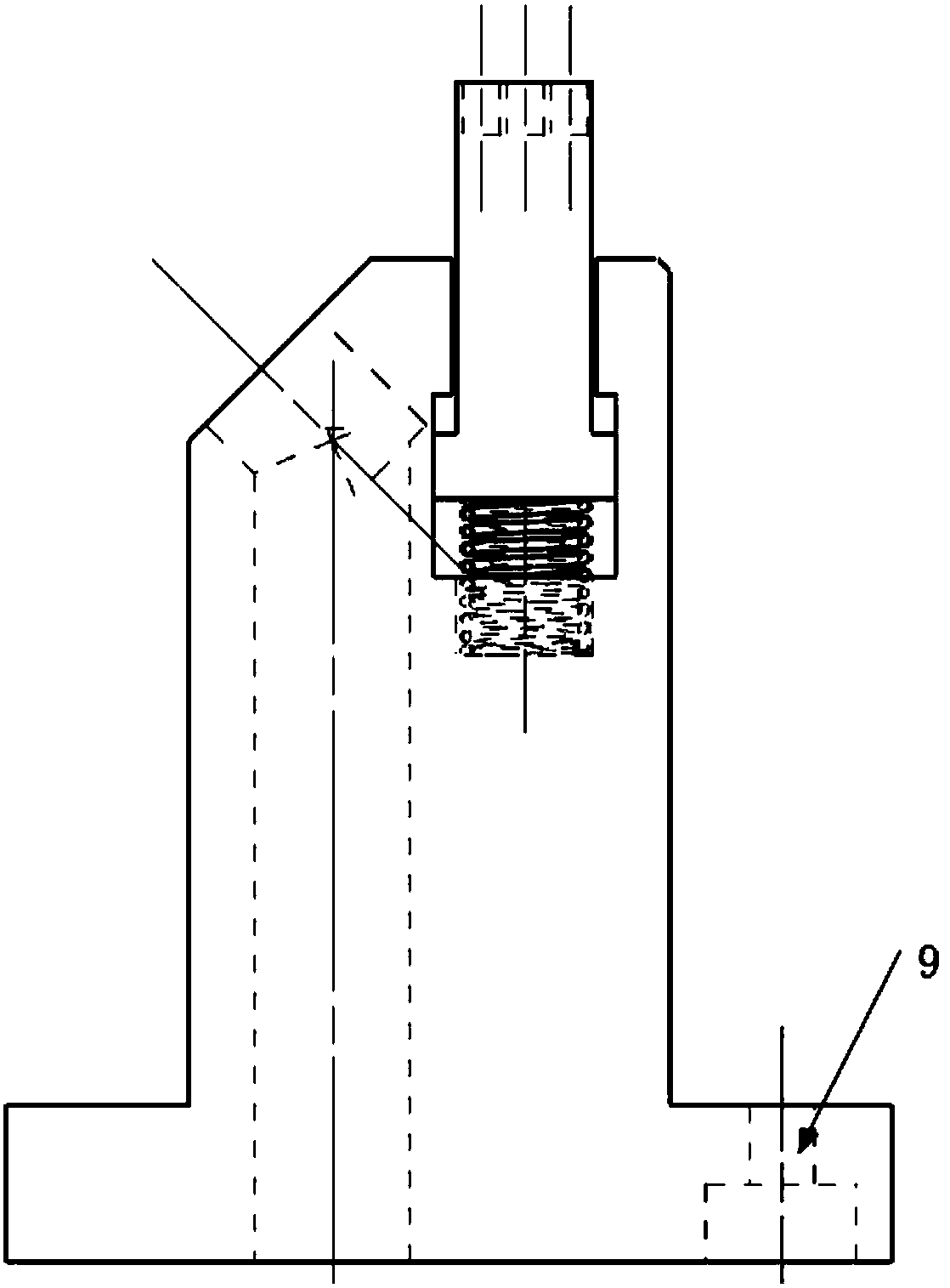

[0033] Between the tilting pads 2 of the tilting pad sliding bearings, an oil inlet nozzle 4 and a hot oil partition device 3 are arranged. The cold lubricating oil reaches the bearing pressure equalizing oil groove 7 through the lubricating oil pipeline, and the oil entering the oil inlet nozzle 4 channel 6;

[0034] The oil inlet channel 6 is inclined at 45°, so that the cold lubricating oil can more easily enter the gap between the tilting pad 2 and the rotor 1, forming a dynamic pressure oil film to support the weight of the rotor 1 and take away the friction generated by the rotation of the rotor 1 of heat, the hot oil is discharged from the other side of the tilting pad.

[0035] The oil inlet channel is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com