Pulley system of variable power crane hoisting hook and integrated system thereof

A technology of cranes and hooks, applied in the direction of load block, load hanging components, transportation and packaging, etc., can solve the problems of heavy workload, cost increase, waste, etc., and achieve the effect of small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

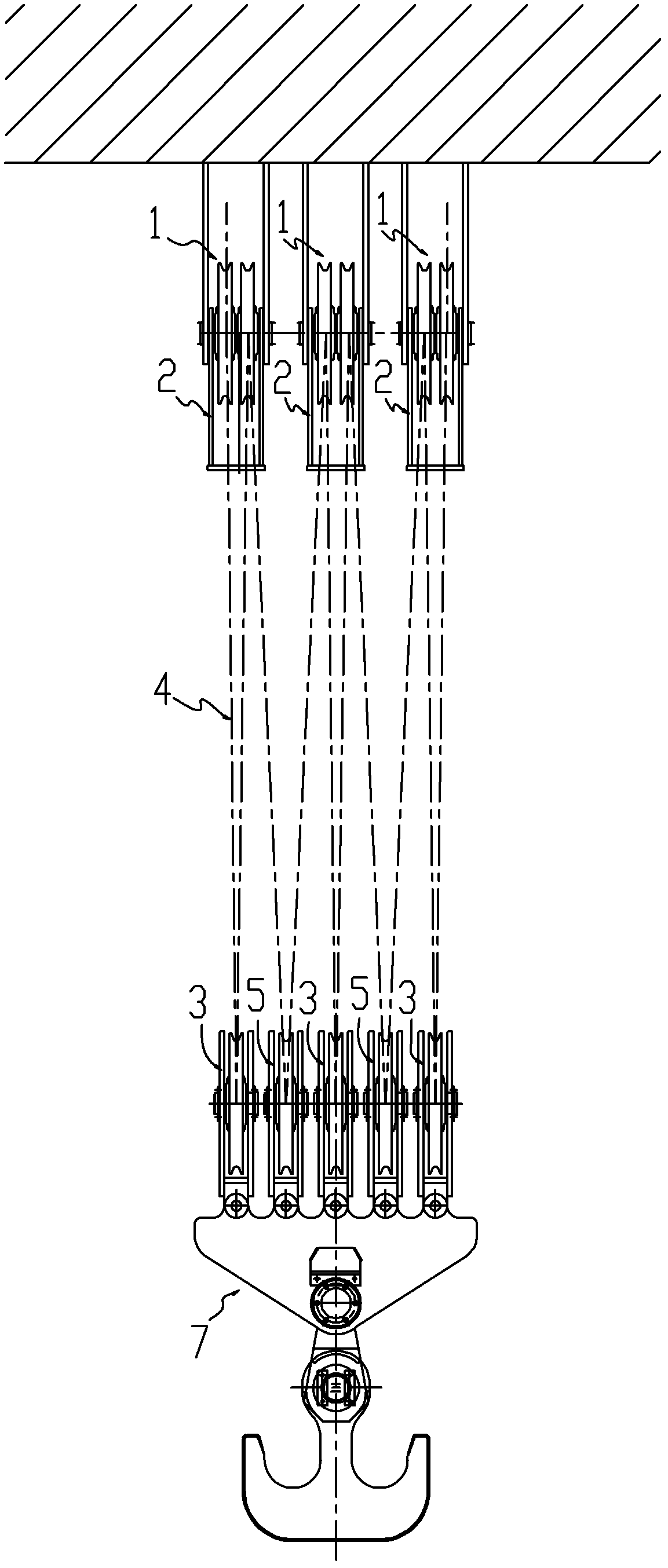

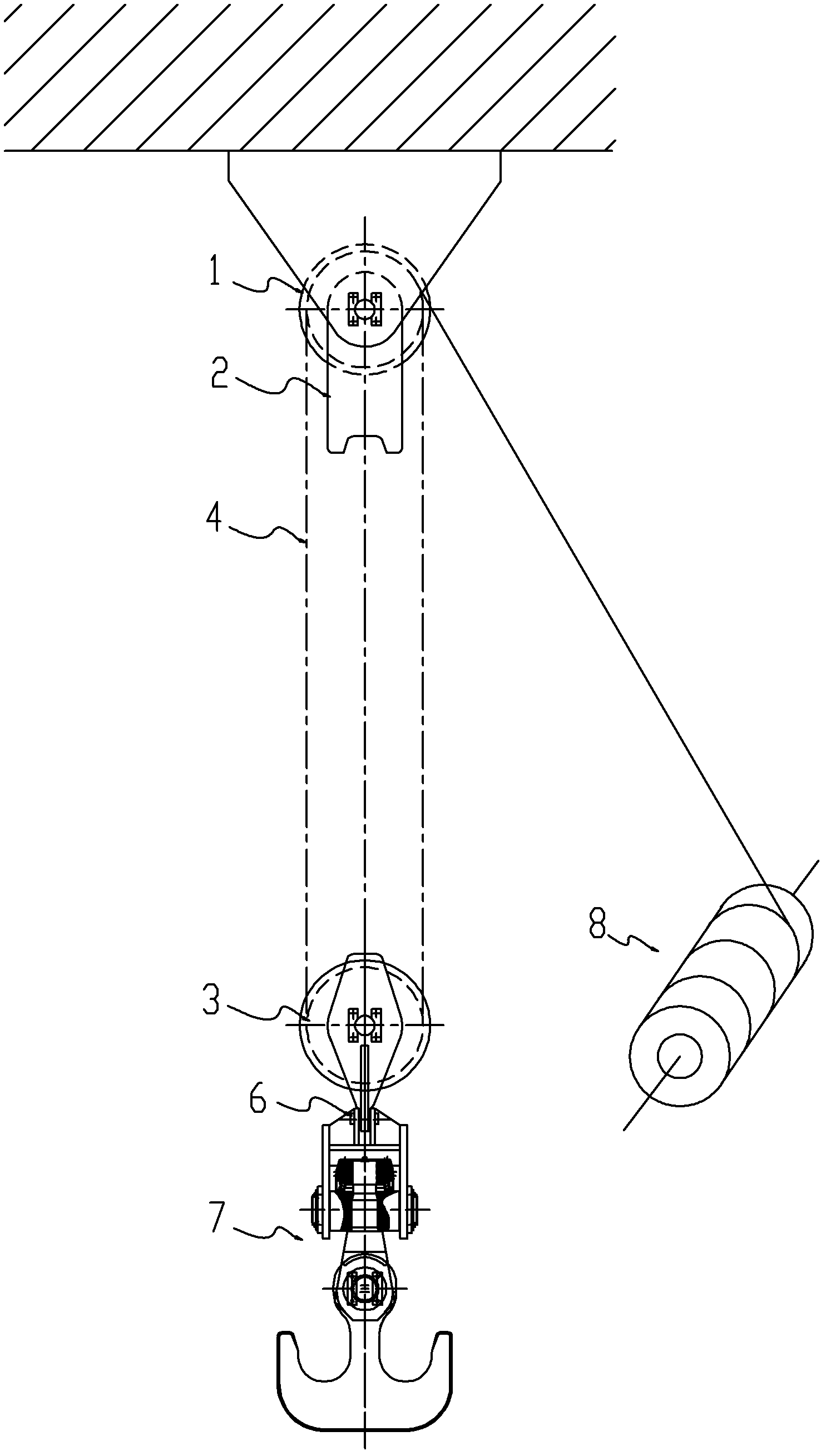

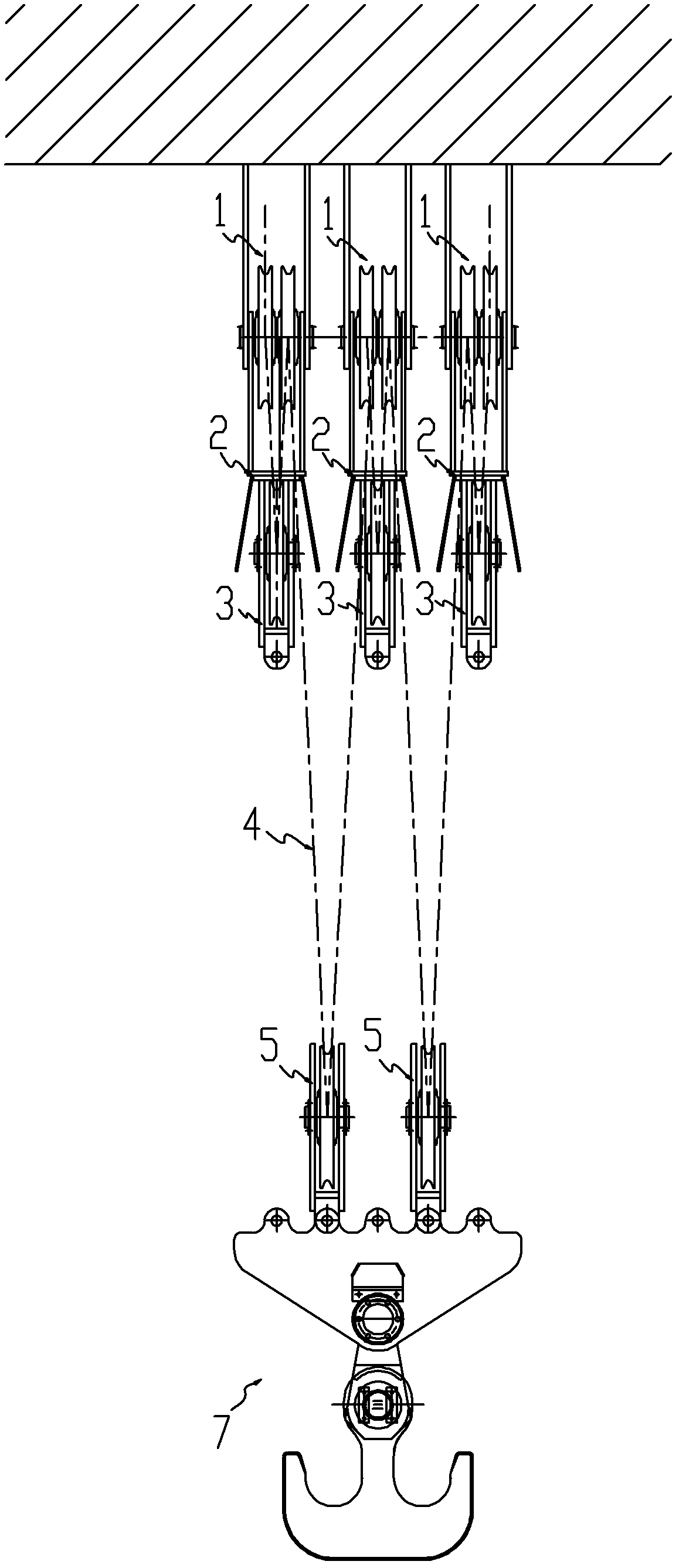

[0024] Combine figure 1 versus figure 2 , A crane variable magnification hoisting hook block system, including a fixed pulley group 1, hook pulley group 5, hook group 7, steel wire rope 4 and hoisting winch 8. The hook pulley group is connected to the hook group, and the wire rope is composed of The hoisting winch starts and winds around the fixed pulley block and hook pulley block. The above hook group is equipped with an adjustable pulley group 3 that can be used as a component of the crane pulley group. A detachable connection structure is adopted between the adjustable pulley group and the hook group. For example, the adjustable pulley group is connected through a connecting pin 6, a shackle, a latch or a card. It is connected to the hook group by way of buckle. The number of adjustable pulley groups mentioned above can be one or more groups. In this example, the number of adjustable pulley groups is three; the number of pulleys in each adjustable pulley group can be one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com