Centrifugal fan for garbage disposer

A centrifugal fan and garbage disposal technology, which is applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve the problems of poor fan installation reliability, high vibration and noise, and is not easy to gas leakage, vibration and noise Small, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

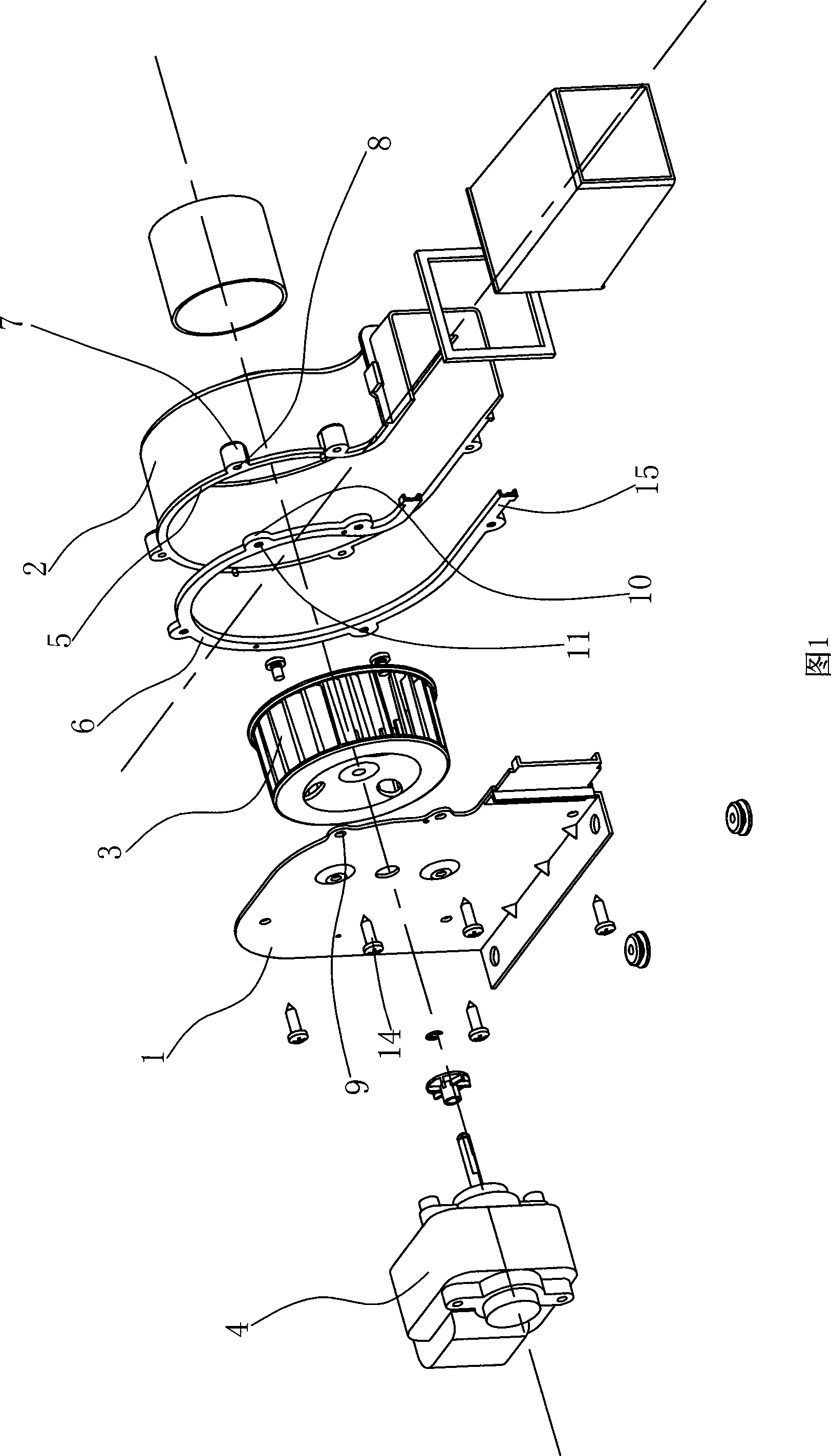

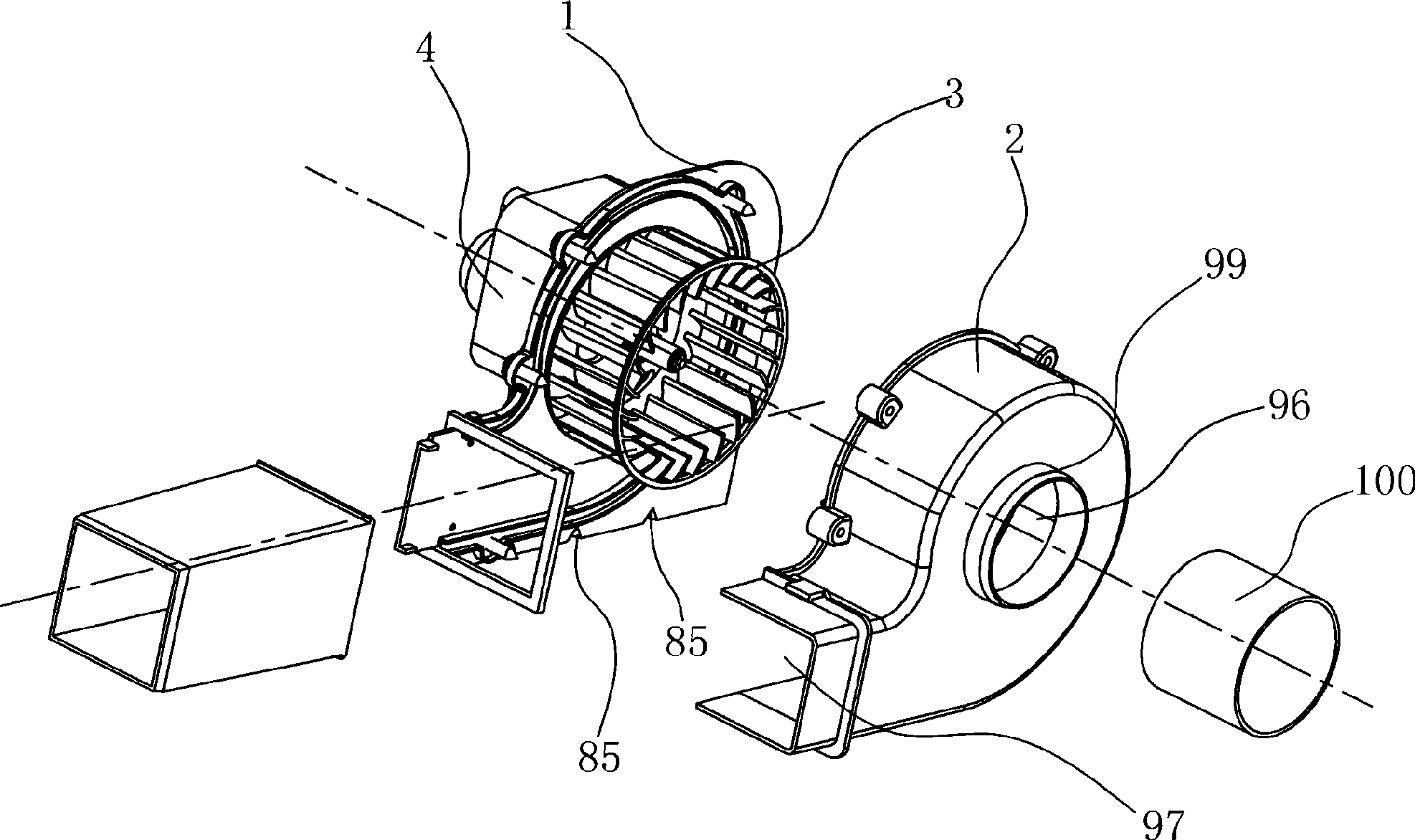

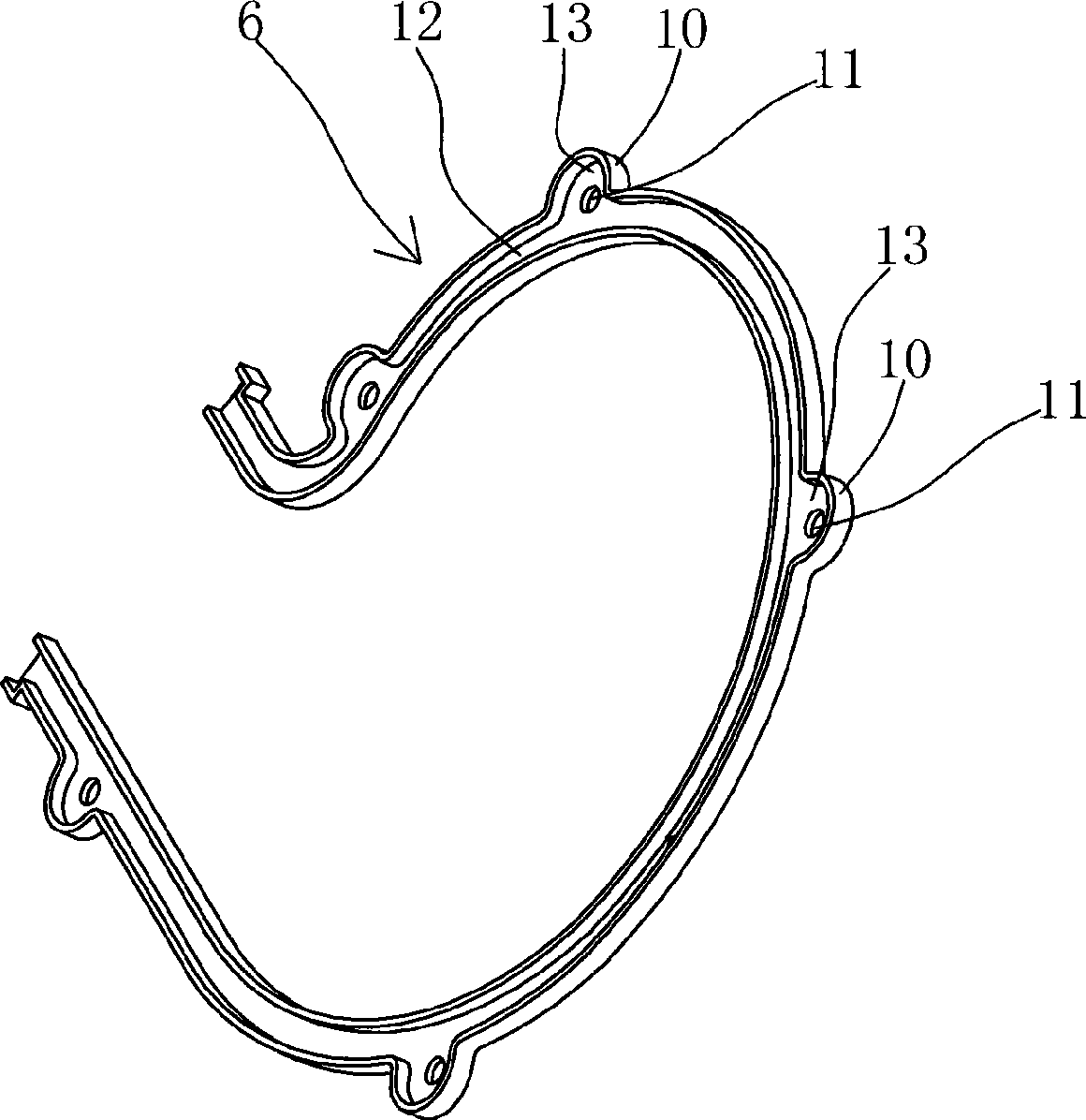

[0027]Embodiment 1: As shown in Figure 1, one side of the mounting plate 1 is provided with a bellows 2, the cavity surrounded by the mounting plate 1 and the bellows 2 is provided with a wind wheel 3, and the other side of the mounting plate 1 is provided with a motor 4 , the output shaft of the motor 4 passes through the mounting plate 1 and is connected to the wind wheel 3 in transmission, the opening edge 5 of the bellows 2 is attached to the mounting plate 1, and the bellows 2 is formed with four cylindrical convex parts 7 arranged at intervals near the opening edge 5 , one end surface of the cylindrical convex part 7 is flush with the opening edge 5 of the bellows 2, the cylindrical convex part 7 is provided with a threaded hole 8, and the mounting plate 1 is provided with a channel corresponding to the threaded hole 8 on the cylindrical convex part 7 Holes 9; a sealing ring 6 is arranged between the opening edge 5 of the bellows 2 and the mounting plate 1, and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com