Dual temperature tunnel type waste rubber cracking furnace

A waste rubber, tunnel-type technology, used in coke ovens, special forms of dry distillation, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as oil quality, safety hazards, environmental pollution, etc., to reduce production cycles, facilitate installation and inspection, The effect of improving safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

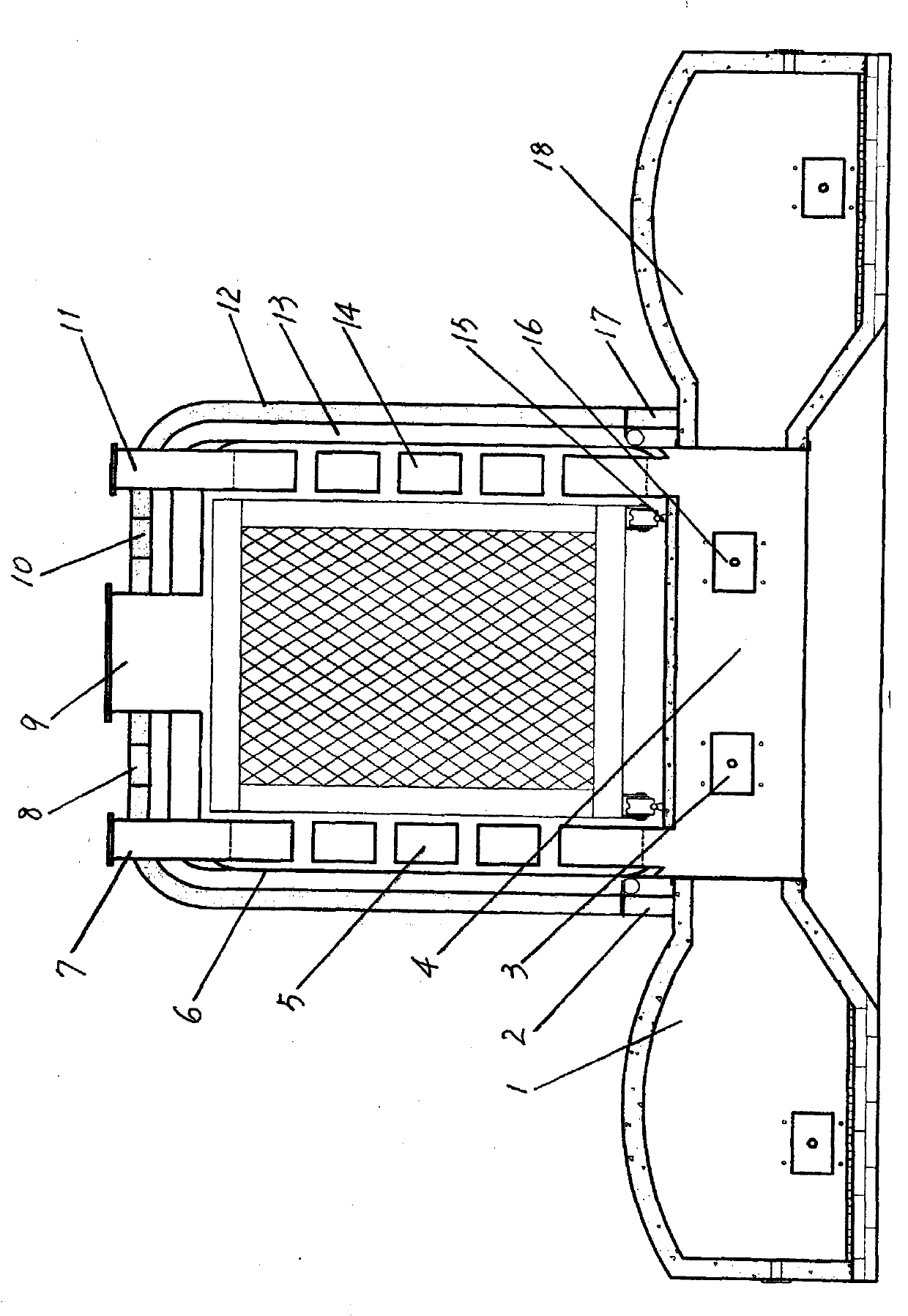

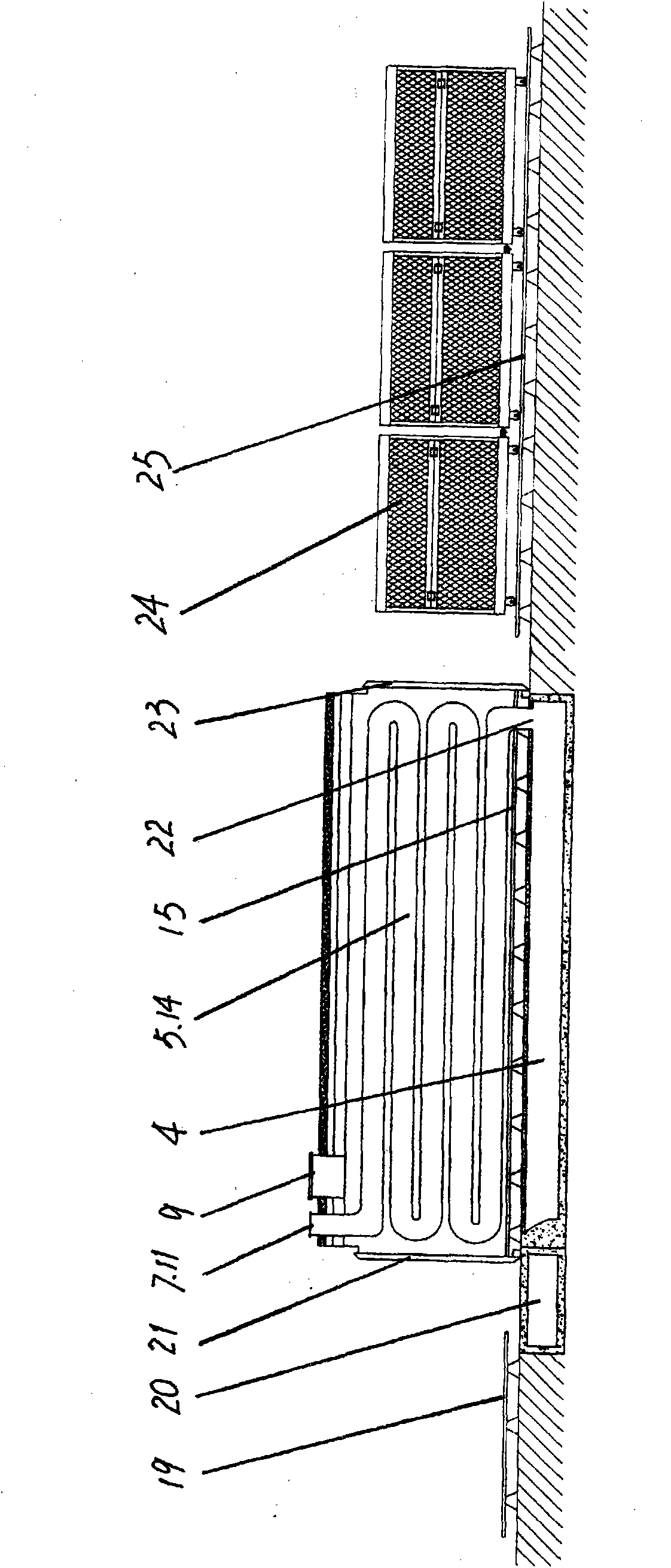

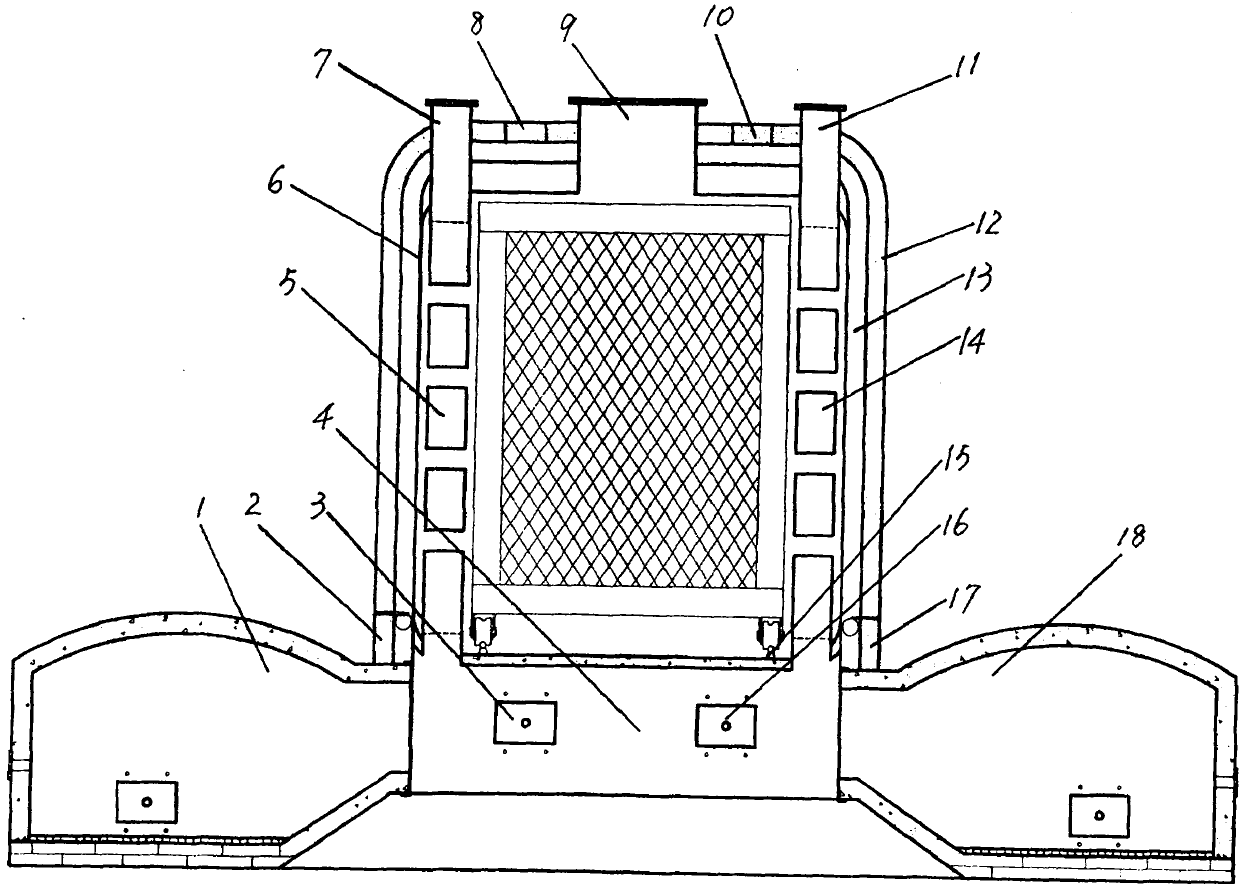

[0010] The invention is attached figure 1 , 2 As shown, it is a fixed rectangular parallelepiped tunnel furnace with a rectangular cross section, and the inner top of the furnace body 6 has arc-shaped inner angles on both sides; at the bottom of the tunnel furnace is a flat tube hot air channel 4 covering the bottom of the furnace body. One end of the furnace body 6 is provided with a combustion furnace 1 and 18 on both sides respectively, which are respectively connected to the two connection ports 20 on both sides of the flat tube hot air channel 4; , on both sides of the other end of the flat tube hot air channel 4, there is a hot air outlet 22 respectively, respectively connected to the coil-shaped hot-air channels 5,14 on the inner walls of the two sides of the tunnel furnace, and the flue gas outlets 7 of the coil-shaped hot-air channels 5,14 , 11 are located at the top of the tunnel furnace and are connected with the flue gas treatment device outside the furnace; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com