Preparation method and application of high-purity dense spherical molybdenum powder

A molybdenum powder and densification technology is applied in the field of spherical metal powder material preparation, which can solve the problems of difficult control of powder particle size, poor fluidity and low density of molybdenum powder, and achieves the effects of low cost, high density and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention provides a preparation method of high-purity dense spherical molybdenum powder, comprising the following steps:

[0034] Step 1, mixing reduced molybdenum powder, binder and deionized water to make slurry;

[0035] Specifically, the reduced molybdenum powder described in the embodiment of the present invention is a molybdenum powder prepared by a conventional reduction process, and the preferred Fischer particle size range of the reduced molybdenum powder is 0.5 μm-6 μm, and the purity is greater than 99.9% in terms of mass percentage; The binding agent can be polyvinyl alcohol, polyethylene glycol, stearic acid, paraffin and other polymer bases and paraffin-based binding agents, preferably polyvinyl alcohol (PVA);

[0036] In the embodiment of the present invention, first mix the binder and deionized water uniformly to make solution A, then add reduced molybdenum powder into solution A, and stir it until it is evenly mixed to mak...

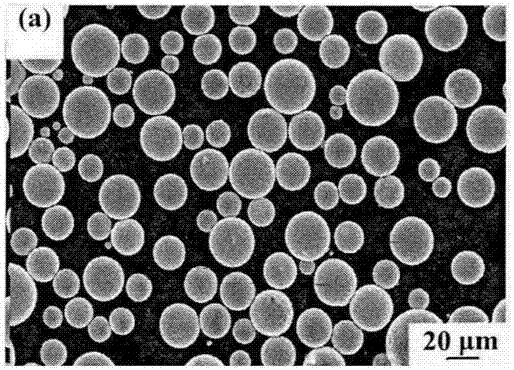

Embodiment 1

[0062] The preparation of high-purity dense spherical molybdenum powder for 3D printing with a particle size ranging from 10 μm to 20 μm comprises the following steps:

[0063] In step 1, conventional reduced molybdenum powder with a purity greater than 99.9% and a Fischer particle size range of 0.5 μm-1 μm is selected as the basic material. Polyvinyl alcohol was used as a binder, and it was uniformly mixed with deionized water to prepare solution A. The content of polyvinyl alcohol in solution A was 2% by mass fraction. Add the reduced molybdenum powder into the solution A, and mechanically stir until the mixture is evenly mixed to form a slurry B. The mass percentage of the solid phase of the slurry B is 30%.

[0064] Step 2. Spray and granulate the slurry B on a centrifugal spray dryer. The air inlet temperature of the spray drying is 170°C, the air outlet temperature is 130°C, the radius of the atomizing disc is 0.15m, and the rotation speed is 15000r / min. The pressure is...

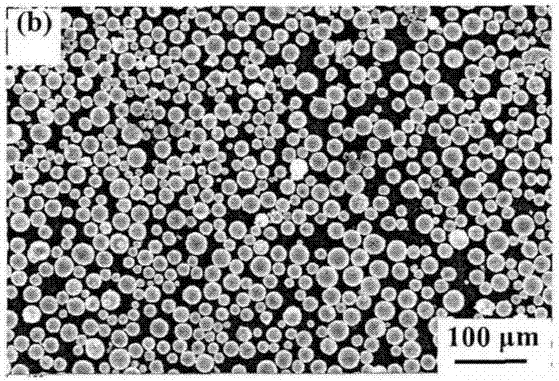

Embodiment 2

[0073] The preparation of high-purity dense spherical molybdenum powder for 3D printing with a particle size of 20 μm-30 μm comprises the following steps:

[0074] In step 1, conventional reduced molybdenum powder with a purity greater than 99.9% and a Fischer particle size range of 2 μm-4 μm is selected as the basic material. Polyvinyl alcohol was used as a binder, and it was uniformly mixed with deionized water to prepare solution A, and the content of polyvinyl alcohol in solution A was 5% by mass fraction. Add the reduced molybdenum powder into the solution A, and mechanically stir until the mixture is evenly mixed to form a slurry B. The solid phase mass percentage of the slurry B is 40%.

[0075] Step 2. Spray and granulate the slurry B on a centrifugal spray dryer. The air inlet temperature of the spray drying is 200°C, the air outlet temperature is 150°C, the radius of the atomizing disc is 0.15m, and the rotation speed is 12000r / min. The pressure is 0.5MPa, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com