Compound coate with with powder core and its making process

A technology of composite powder and core coating, which is applied in the field of composite powder core cored wire and its manufacturing, can solve the problems of industrial application obstacles, change of calcium vaporization point, and low efficiency of magnesium, so as to reduce the negative impact of processing costs and reduce the Effectiveness of cost reduction and utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

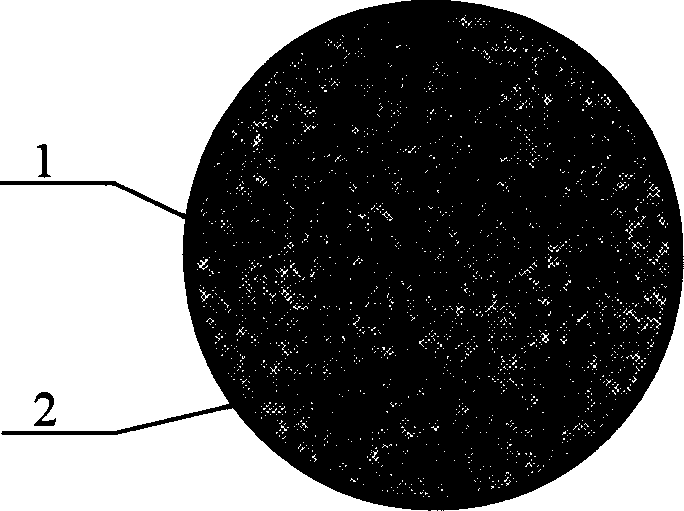

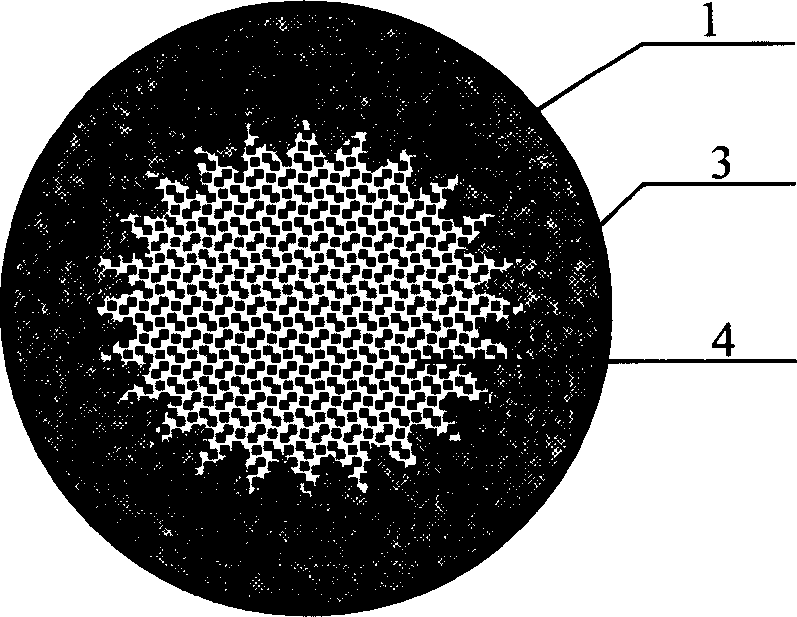

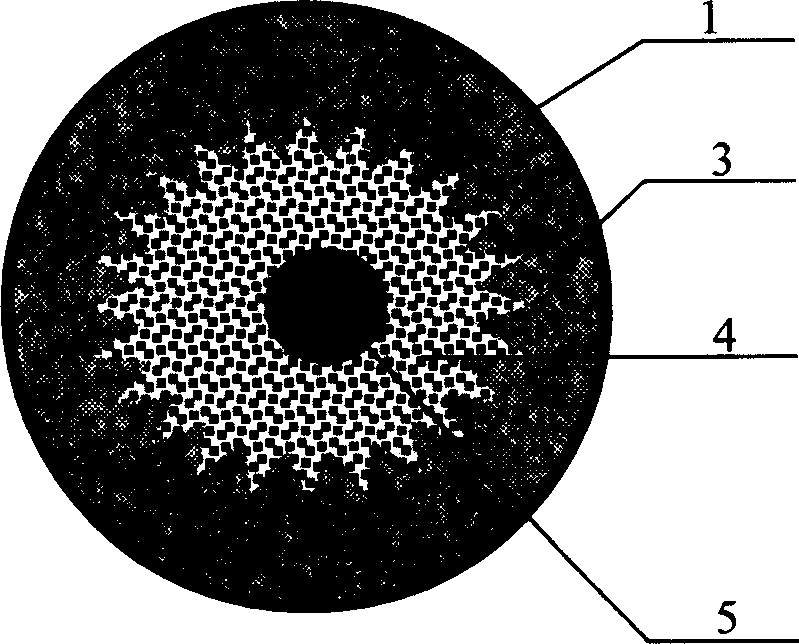

[0044] Referring to the accompanying drawings, the composite powder core cored wire of the present invention is composed of a steel strip 1 and a powder material 2 wrapped in the steel strip 1, and the powder material to be added in the cored wire is divided according to the function of each functional element. Two parts are prepared, and one part of the powder contains functional elements whose vaporization point is lower than the temperature of the molten metal to be treated, which is called internal powder 4; the other part of the powder contains functional elements whose vaporization points are higher than It is equal to the temperature of the molten metal to be processed, which is called the outer powder material 3; the inner powder material 4 is wrapped in the outer layer powder material 3, so that the outer layer powder material 3 forms a wrapping layer on the inner powder material 4, and the formed wrapping layer The thickness is not less than 1.2mm. According to the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com