Raw gas cooling and fractionation method and coking apparatus

A fractionation device and raw gas technology, applied in the field of coking, can solve the problems of increased raw gas volume, increased energy consumption, corrosion, etc., and achieve the effects of improving classification processing efficiency, reducing energy consumption and pollution, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

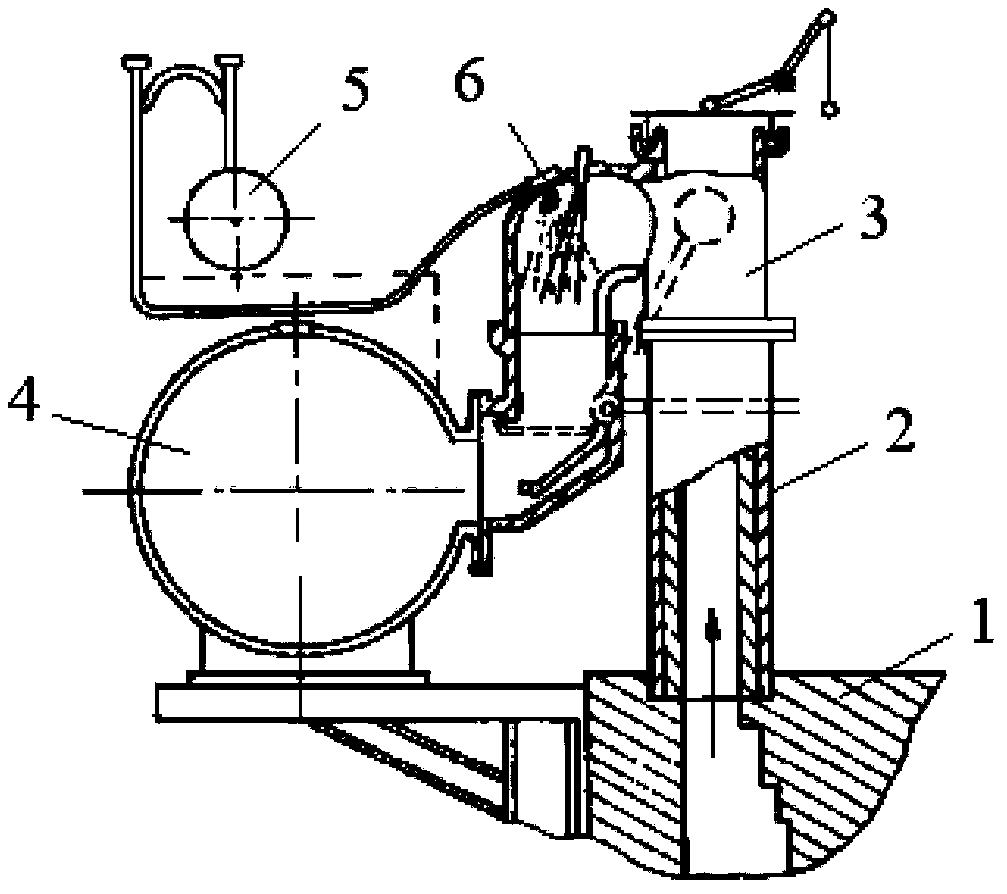

[0053] Embodiment 1 provides a raw coal gas cooling and fractionation method, which is used to recycle the raw coal gas discharged from the coke oven coking chamber, and the raw coal gas cooling and fractionation method is in the case that the raw coal gas is discharged from the coke oven coking chamber but not cooled In other words, this embodiment does not need to cool the raw coal gas and then heat it to decompose and recover it, and directly utilizes the heat in the high-temperature raw coal gas (temperature 700-650°C) discharged from the coke oven carbonization chamber to recycle it .

[0054] The raw gas cooling fractionation method provided in the first embodiment is to cool the high-temperature raw gas step by step, and in the process of step-by-step cooling, different fractions in the raw gas are extracted step by step according to the boiling point of the fractions from high to low, so that the raw gas Gas recycling.

[0055] Specifically, firstly, the raw coal gas ...

Embodiment 2

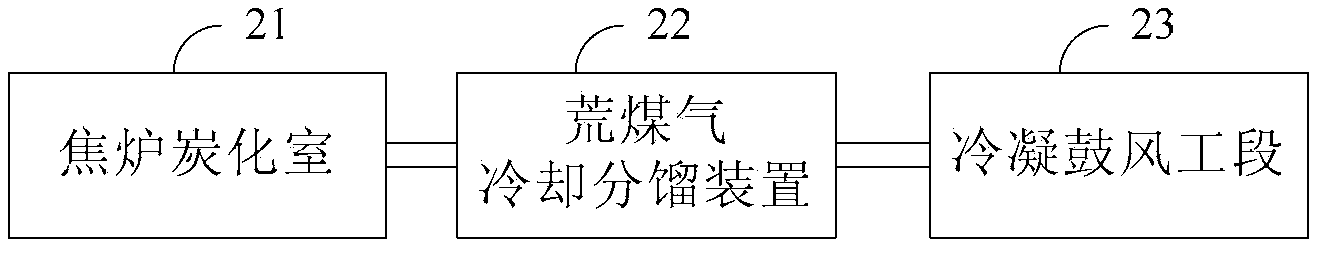

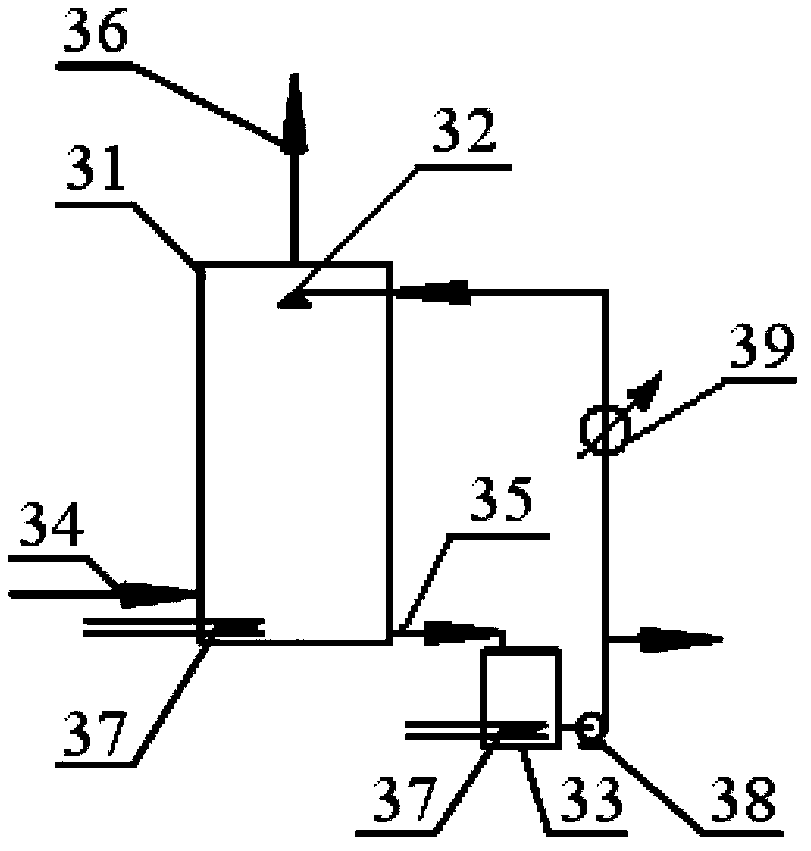

[0062] Embodiment 2 provides a raw gas cooling fractionation device, figure 2 It is the principle block diagram of the crude gas cooling fractionation device. see figure 2 , the crude gas cooling fractionation device includes a coke oven carbonization chamber 21 and a condensation blast section 23, the raw coal gas discharged from the coke oven carbonization chamber 21 is transported to the condensation blast section 23, where the coke oven carbonization chamber 21 and the condensation blast section 23 There is also a raw gas cooling and fractionating device 22 for recycling the raw gas discharged from the coking chamber 21 of the coke oven.

[0063] The raw gas cooling and fractionating device 22 adopts a step-by-step cooling method for the raw gas, and during the step-by-step cooling process, different fractions in the raw gas are extracted step by step according to the boiling point of the fractions from high to low.

[0064] In the second embodiment, the crude gas cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com