Internal energy integration non-compression reflux device for ethylene separation and process flow thereof

An internal energy and ethylene technology, applied in ethylene production, distillation purification/separation, fractionation, etc., can solve the problem of high energy consumption of ethylene towers and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below by examples.

[0024] The present invention is achieved through the following technical solutions:

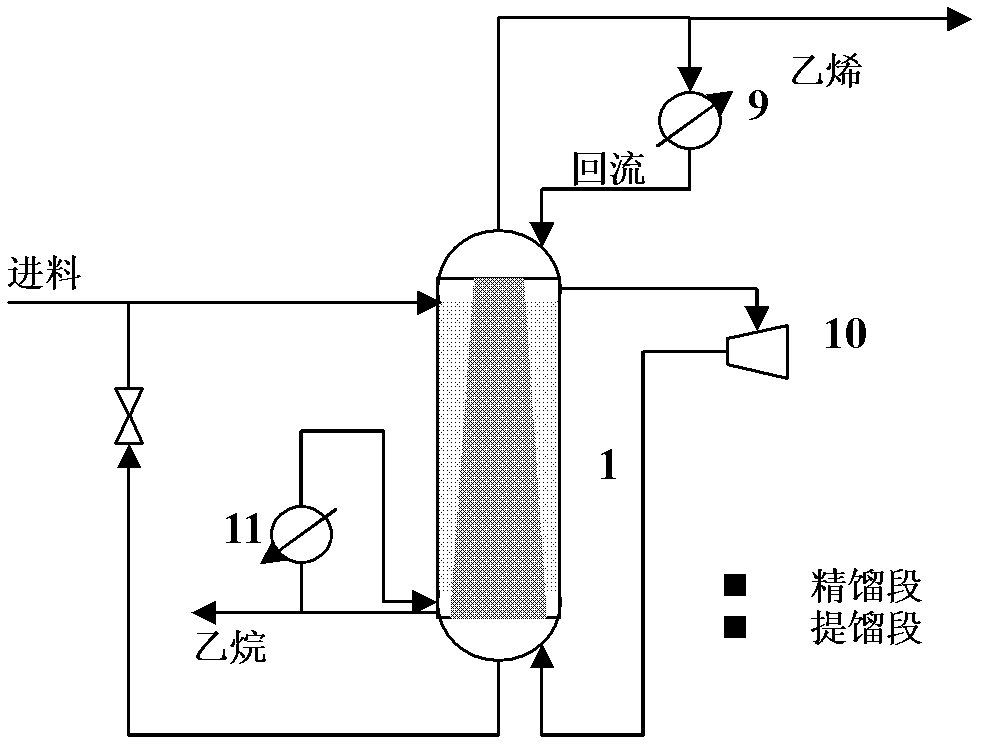

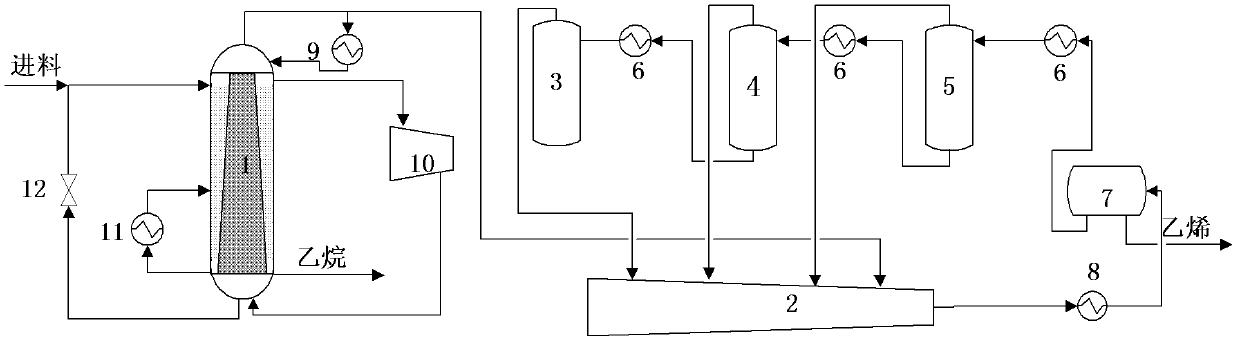

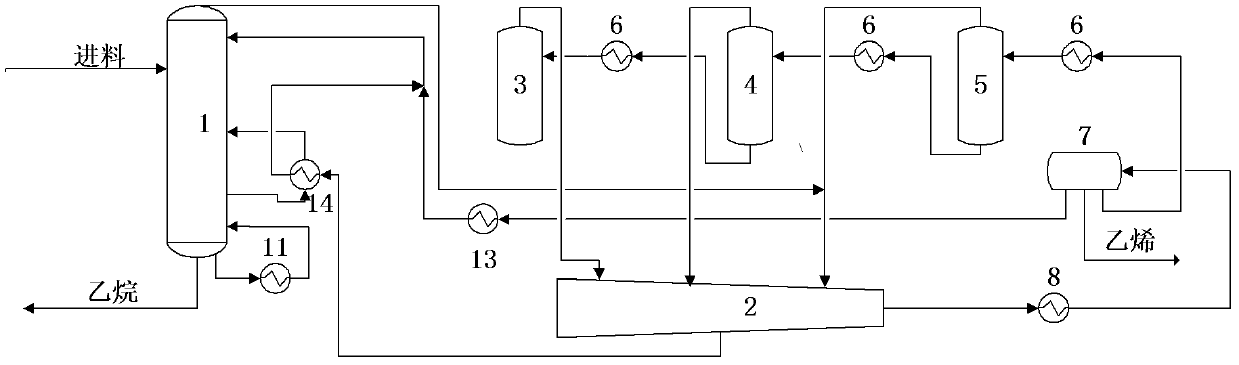

[0025] Such as figure 2 As shown, the gas phase material at the bottom of the demethanizer tower and the gas-liquid mixture material at the top of the deethanizer tower enter the ethylene tower (1) respectively in the previous process of the ethylene plant, and the ethylene gas produced at the top of the rectification section enters the ethylene refrigeration Compressed by the compressor (2), cooled and condensed by the ethylene refrigerant condensing cooler (8), enters the ethylene refrigerant buffer tank (7) as ethylene product and ethylene refrigerant; after the ethylene refrigerant comes out of the buffer tank (7), Enter the third-stage suction tank (5) of the ethylene refrigeration compressor, the second-stage suction tank (4) of the ethylene refrigeration compressor, and the first-stage suction tank (3) of the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com