Energy saving method and equipment for rectification separation

A rectification separation and equipment technology, which is applied in the field of energy-saving rectification separation and equipment, can solve the problems of consuming the heat load of the condenser, the heat load of the reboiler, inconvenient start-up operation, and no thermal coupling, etc., so as to reduce the heat load of condensation, The effect of saving heat removal heat load and reducing comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

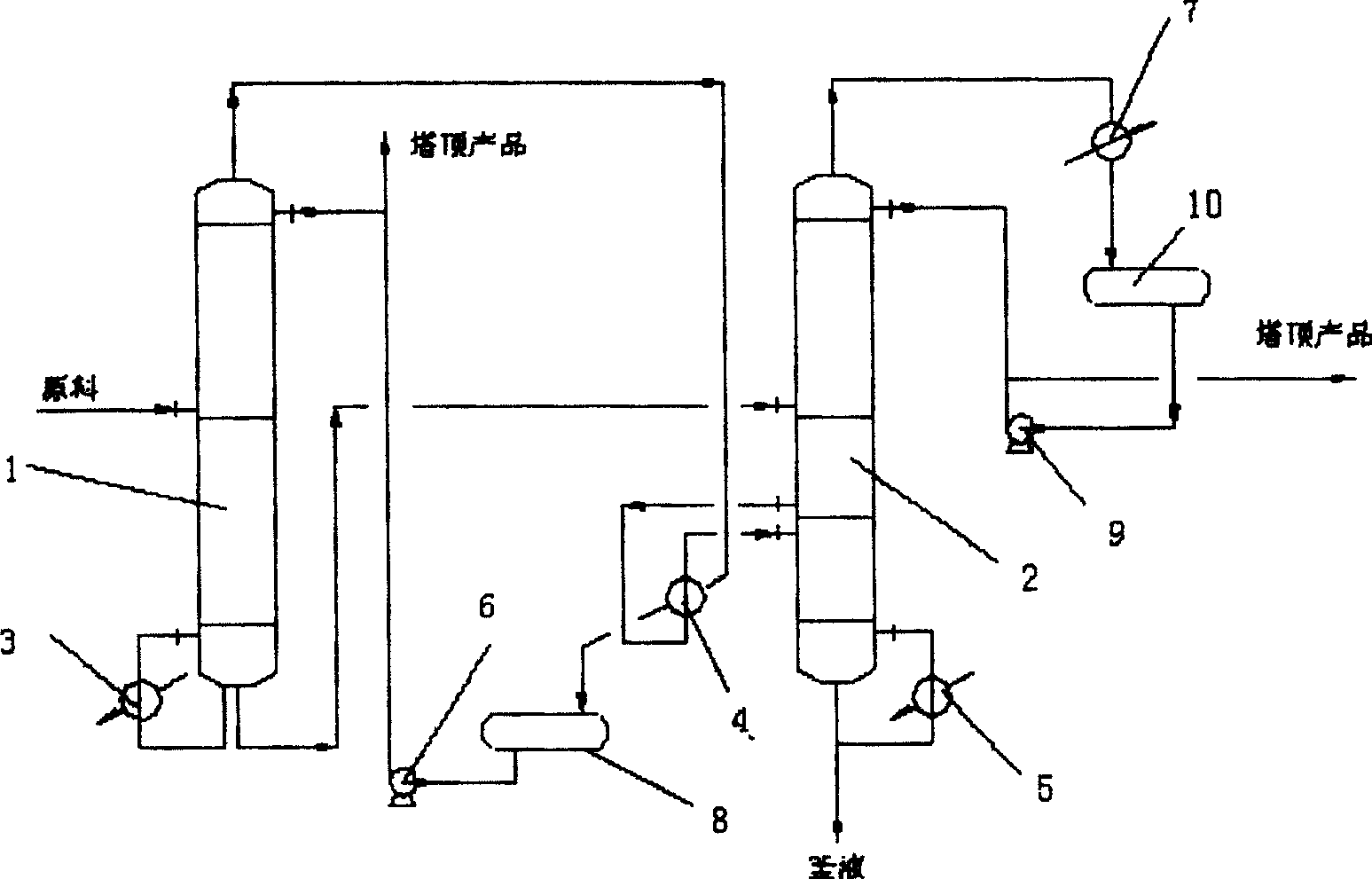

[0031] In this embodiment, the single-column rectification column is changed to double-column double-pressure series connection, thermal coupling of condenser and intermediate reboiler, and additional adjustment of reboiler. The flow chart is shown in the appendix image 3 .

[0032] It is composed of two rectification towers A and B, the bottom of tower A (1) is connected with a reboiler (3), the outlet at the bottom of the tower is connected with the inlet of tower B (2), and the outlet at the top of tower A is connected with The intermediate reboiler (4) is connected, the intermediate reboiler is connected with a reflux tank (8), the reflux tank is connected with the top inlet of the A tower through the reflux pump (6), and the intermediate reboiler is connected with the lower part of the B tower. One end of the adjustable reboiler (5) is connected to the bottom of the B tower, and the other end is connected to the still liquid outflow pipeline at the bottom of the B tower....

Embodiment 2

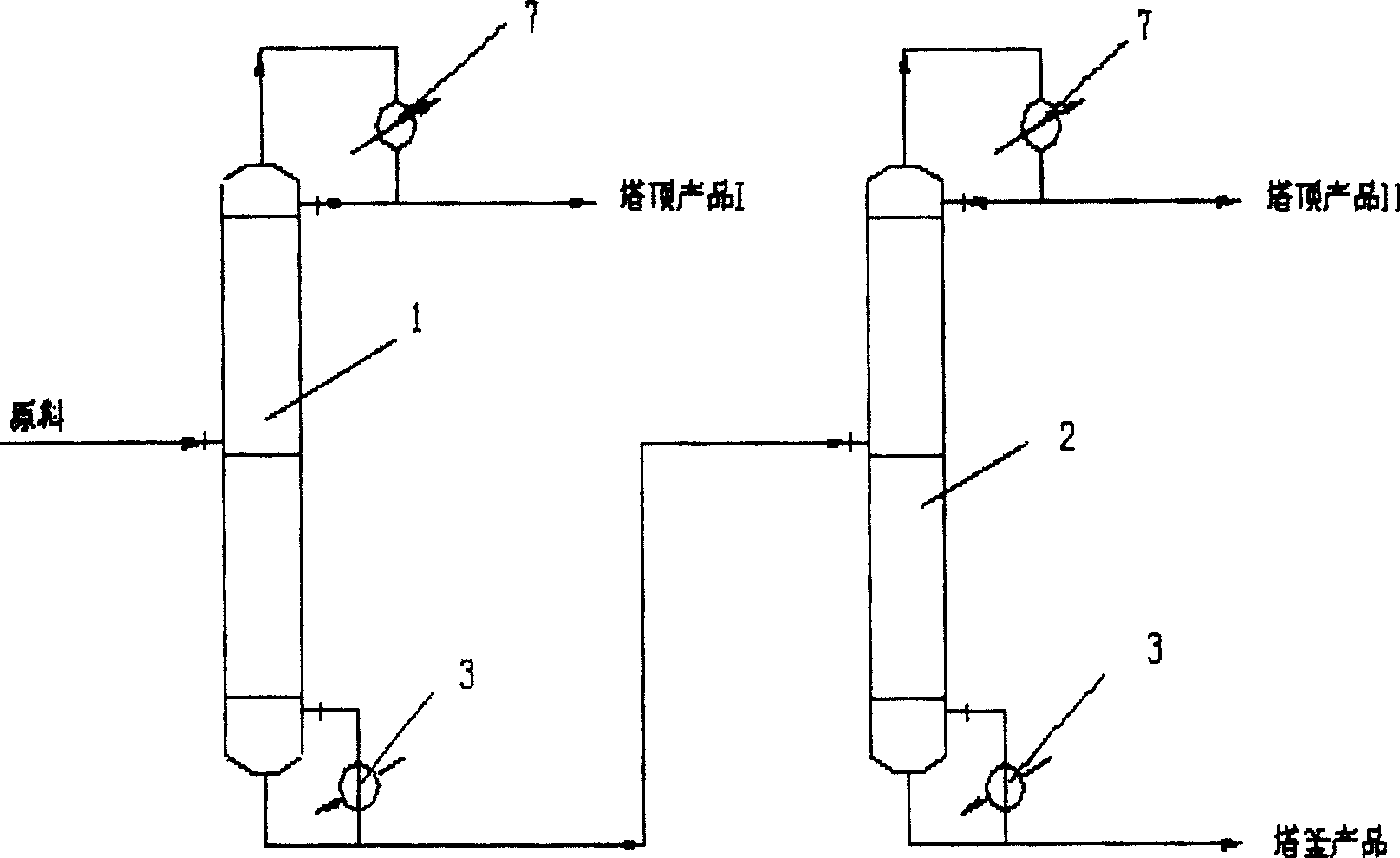

[0035] In this embodiment, the double-tower rectification tower is changed to a double-tower double-pressure series connection, a thermal coupling between the condenser and the intermediate reboiler, and an additional adjustment of the reboiler. When the feed is in the A tower, the flow diagram is shown in the appendix. Figure 4 , technological process is as embodiment 1, and fresh raw material first enters A tower, and tower top steams product I, removes heat through the condenser of B tower and intermediate reboiler, condenses, enters reflux tank buffer, and part reflux returns tower top, The remaining part is produced as product I. The tower is equipped with a typical reboiler, and the kettle liquid is extracted and enters the B tower. The light product II is evaporated from the top of the B tower. The classic condenser removes heat and condenses, and enters the reflux tank. Buffering, part of the reflux returns to the top of the tower, and the rest is also extracted as pro...

Embodiment 3

[0037] In this embodiment, the double-tower rectification tower is changed to a double-tower double-pressure series connection, a condenser and an intermediate reboiler are thermally coupled and an additional adjustment of the reboiler process is carried out. The process equipment is the same as in Example 1. When the feed is in the B tower, See attached Figure 5, the fresh raw material first enters the B tower, and the product I is steamed from the top of the tower, which is removed and condensed by the typical condenser of the B tower, and enters the reflux tank for buffering, and part of the reflux returns to the top of the tower, and the rest is extracted as the product I. An additional adjustment reboiler is used to ensure the normal operation of the B tower. The bottom liquid of the tower is taken out and enters the A tower. The light product II is distilled from the top of the A tower, and the heat is removed through the condenser and the intermediate reboiler of the B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com