Method for separating pseudocumene from C9 aromatic hydrocarbon

A technology for carbon 9 aromatics and metatrimethylbenzene is applied in the field of separation of metatrimethylbenzene, which can solve the problems of low productivity and high production cost of metatrimethylbenzene, and achieve the effects of avoiding stratification, good compatibility and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

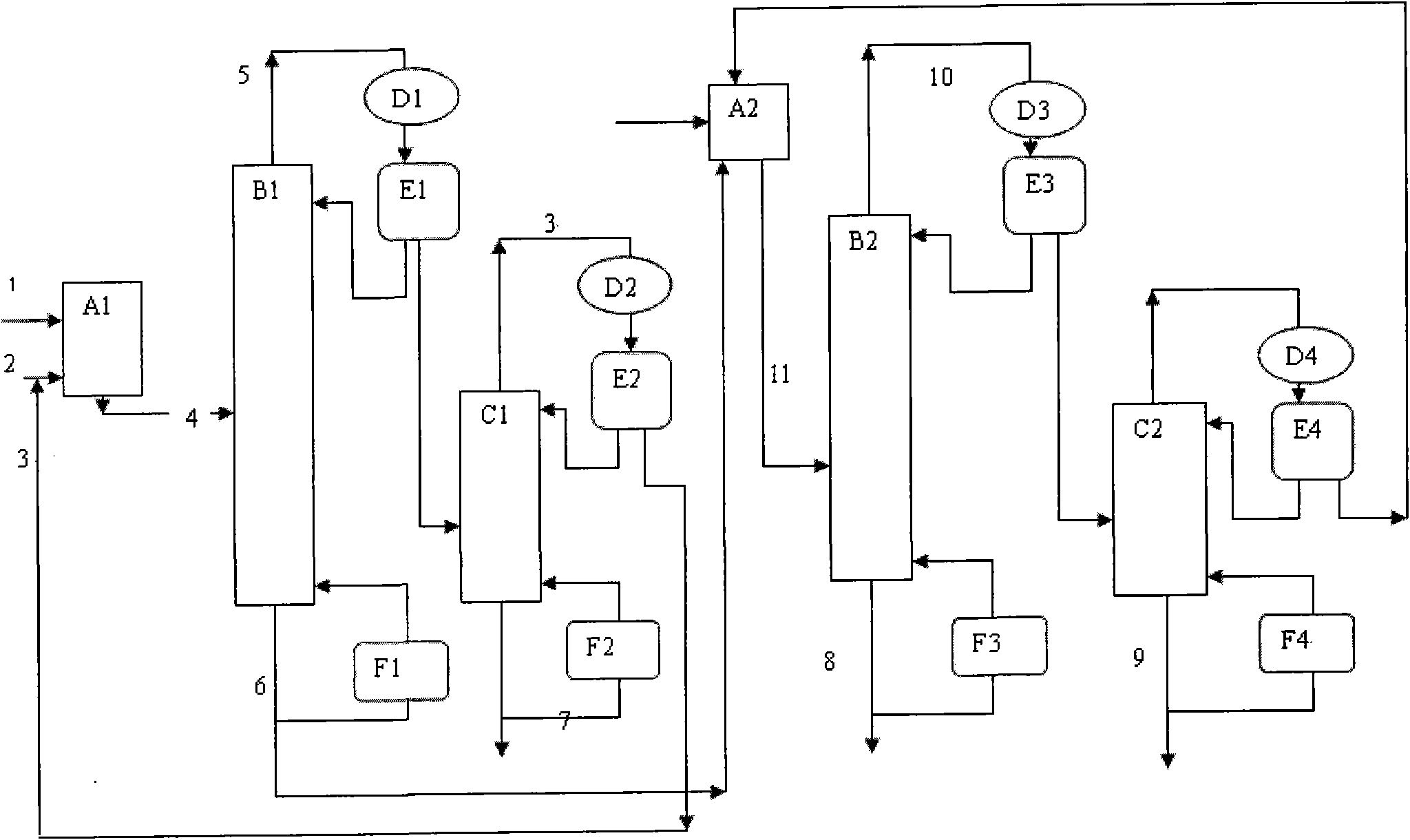

Method used

Image

Examples

Embodiment 1~6

[0039] Carry out by the above-mentioned method for separating unisexamethylene from C9 aromatic hydrocarbons, and concrete process condition, parameter and used catalyzer are shown in Table 3 and Table 4.

[0040] The C9 C9 aromatic hydrocarbon mixture used in the embodiment of the present invention is a reformed C9 aromatic hydrocarbon fraction, which contains 45.2% (weight) of trimethylbenzene, and its specific components and contents are shown in Table 1.

[0041] Table 1 Composition and boiling point of raw materials of C9 aromatics

[0042] component name

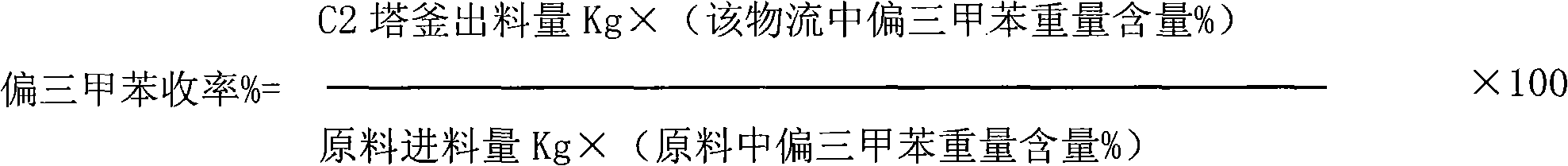

[0043] The yield of C9 aromatics raw material obtained by separation of trimethylbenzene is calculated by the following formula:

[0044]

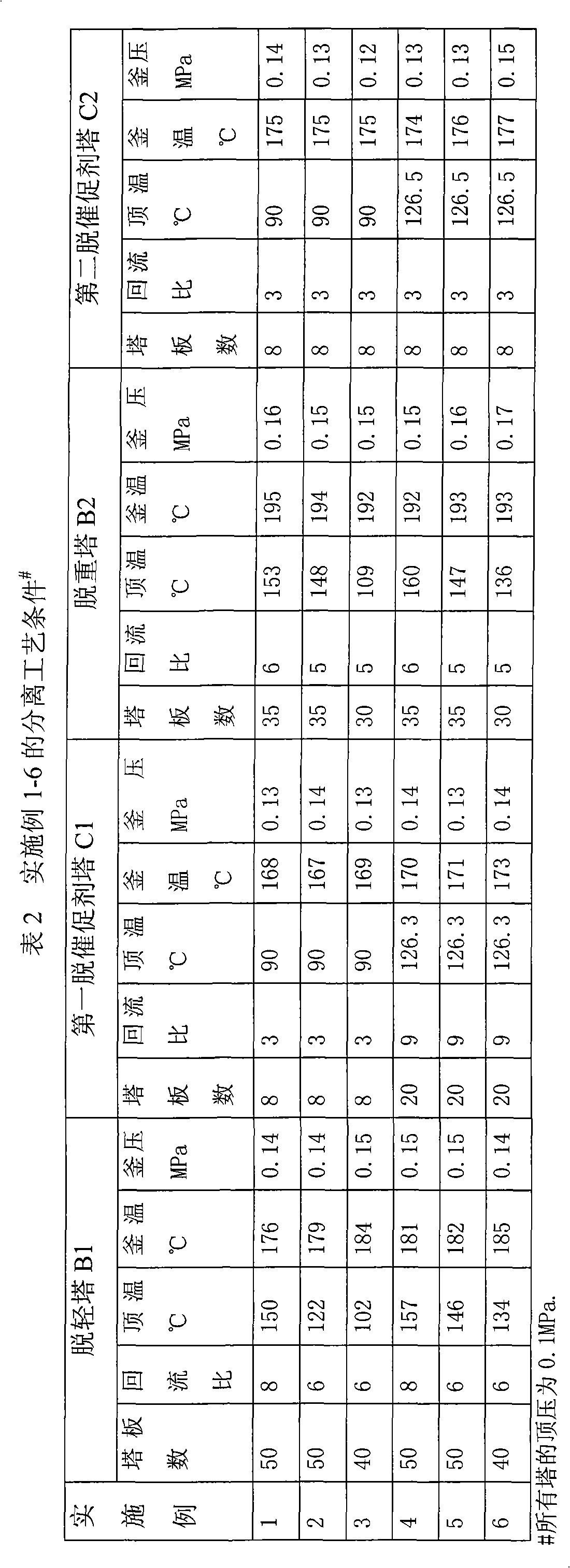

[0045] The separation process condition and separation result of embodiment 1-6 are listed in table 2-4 respectively

[0046]

[0047]

[0048] Table 4 embodiment 1-6 separation result

[0049] Example

[0050] Can find out from above result: accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com