Device and method for synthesizing trioxymethylene by salt effect reactive rectification

A technology of paraformaldehyde and reactive distillation, which is applied in separation methods, chemical instruments and methods, fractionation, etc., can solve the problems of unrelevant reporting, etc., and achieve the effects of reducing energy consumption, reducing the number of trays, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

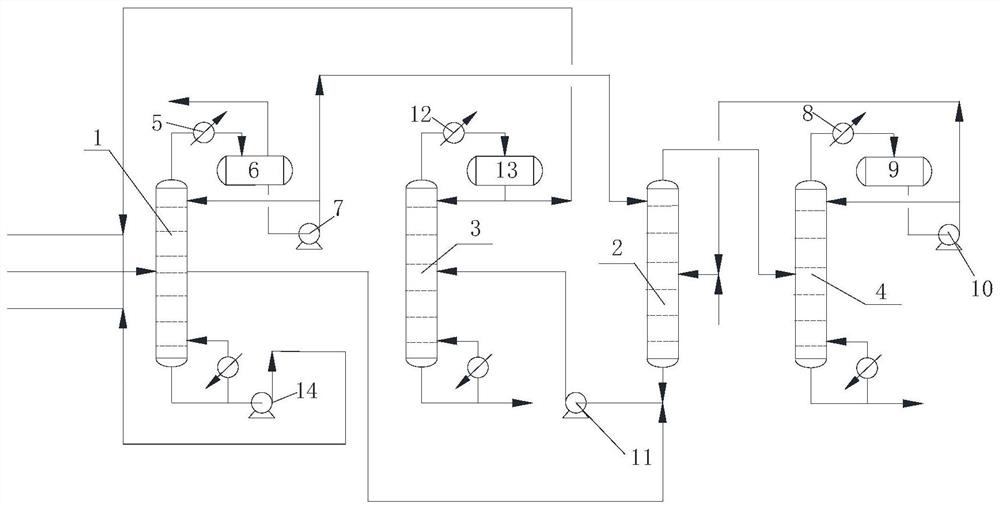

[0033] Embodiment 1: as figure 2Shown, a kind of device of salt effect reactive distillation synthesis paraformaldehyde, it comprises reactive distillation tower 1, extraction tower 2, concentration tower 3 and recovery tower 4, the middle part of reactive distillation tower 1 is provided with feed inlet, The middle material outlet of the reactive distillation tower 1 is connected to the inlet of the pump III 11, the top material outlet of the reactive distillation tower 1 is connected to the material inlet of the condenser I5, and the material outlet of the condenser I5 is connected to the inlet of the reflux tank I6 Connect, the outlet of reflux tank I 6 is connected with the inlet of pump II 7, and the outlet of pump II 7 is connected with the top reflux port of reactive distillation tower 1 and the material inlet of extraction tower 2 respectively; The top material outlet of extraction tower 2 is connected with the recovery The material inlet of tower 4 is connected, and ...

Embodiment 2

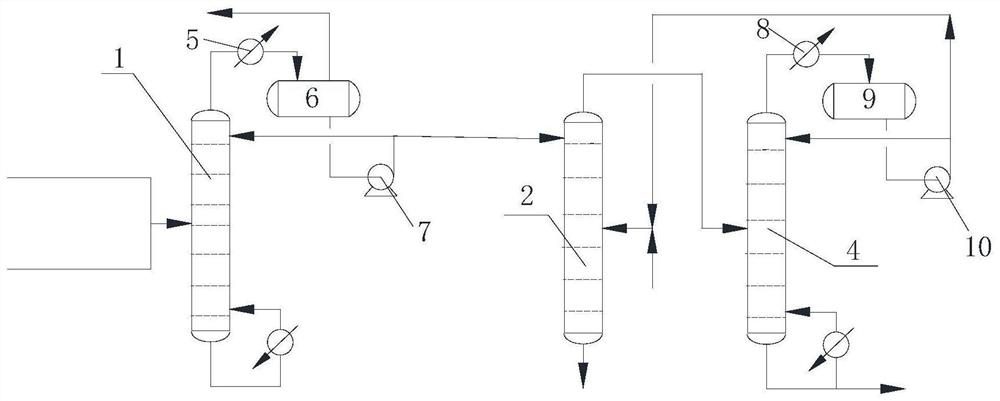

[0035] Embodiment 2: a kind of device of reactive distillation synthesis paraformaldehyde, its difference with embodiment 1 is that there is no concentrating tower, as image 3 As shown, it comprises a reactive distillation tower 1, an extraction tower 2 and a recovery tower 4, the middle part of the reactive distillation tower 1 is provided with a feed inlet, and the top material outlet of the reactive distillation tower 1 is connected with the material inlet of the condenser 15 , the material outlet of condenser I 5 is connected with the inlet of reflux tank I 6, the outlet of reflux tank I 6 is connected with the inlet of pump II 7, and the outlet of pump II 7 is respectively connected with the top reflux port of reactive distillation column 1 and the extraction tower The material inlet of 2 is connected; the top material outlet of extraction tower 2 is connected with the material inlet of recovery tower 4, and the bottom of recovery tower 4 is provided with paraformaldehyde...

Embodiment 3

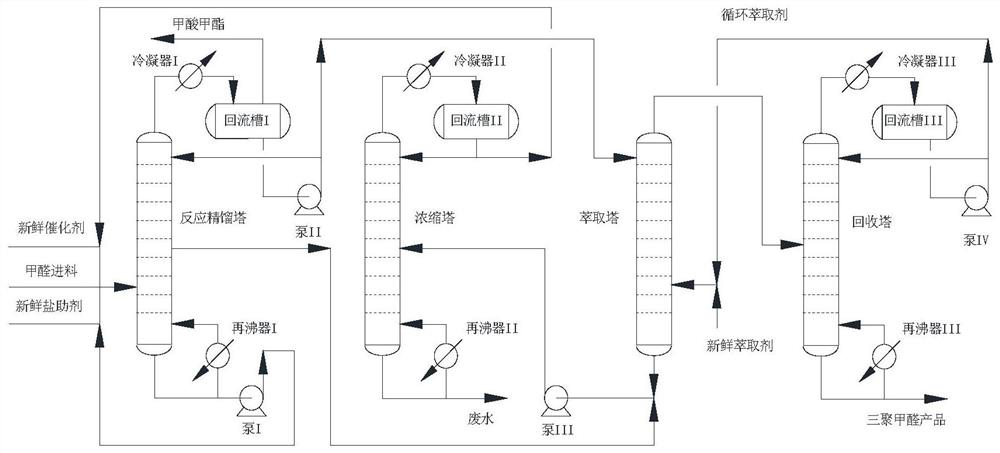

[0037] Embodiment 3: as figure 1 As shown, the method for synthesizing paraformaldehyde by salt effect reactive distillation using the device of Example 1 comprises the following steps: (1) reactive distillation generates a paraformaldehyde synthetic liquid; (2) extracts a paraformaldehyde synthetic liquid to obtain a rich The extract phase containing paraformaldehyde and the raffinate phase rich in water and formaldehyde; (3) the raffinate phase is concentrated and recovered formaldehyde solution; (4) the extraction agent is separated and recovered in the extract phase to obtain a paraformaldehyde product; wherein,

[0038] (1) Reactive distillation generates paraformaldehyde synthesis liquid: formaldehyde solution, catalyst and salt additives are added to the reactive distillation tower through the feed port provided in the middle of the reactive distillation tower, wherein the concentration of the feed formaldehyde solution is 65wt%; The concentration of catalyst sulfuric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com