Air separation fractionating tower system and technology utilizing air separation fractioning tower system to prepare low-purity oxygen

A fractionation tower, low-purity oxygen technology, applied in refrigeration and liquefaction, lighting and heating equipment, liquefaction, etc., can solve the problems of not being able to produce nitrogen and liquid products at the same time, occupy a large area, and limit oxygen production to achieve operating pressure Reduction, equipment investment reduction, the effect of equipment investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

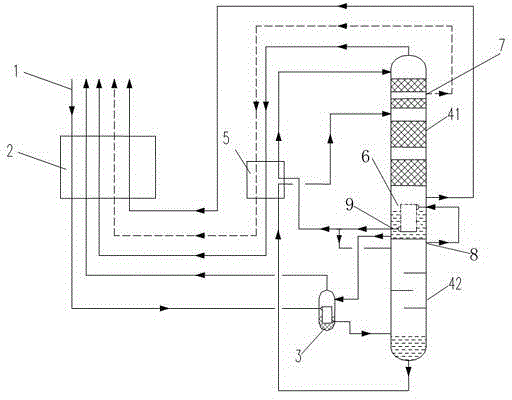

[0031]A kind of air fractionation tower system, comprises the fractionation tower that is made up of fractionation tower upper tower 41, condensation evaporator 6 and fractionation tower lower tower 42, condensation evaporator 6 tops communicate with fractionation tower upper tower 41 bottoms, condensation evaporator bottom 6 and The top of the lower tower 42 of the fractionating tower is connected, and the pressure air pipeline 1 is connected to the main heat exchanger 2, the liquid oxygen evaporator 3 and the lower tower 42 of the fractionating tower in sequence, and the bottom outlet of the lower tower 42 of the fractionating tower is connected to the upper tower 41 of the fractionating tower through the subcooler 5 (fractionation The number of trays of the upper tower 41 is 48) at the 15th-18th tray; the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com