A kind of separation method and device of ethanol and ethyl acetate

A technology of ethyl acetate and ethanol, which is applied in the field of separation of ethanol and ethyl acetate, can solve the problems of large tower load and large reflux, reduce the number of plates and reflux ratio, reduce energy consumption of separation, and reduce system circulating water volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

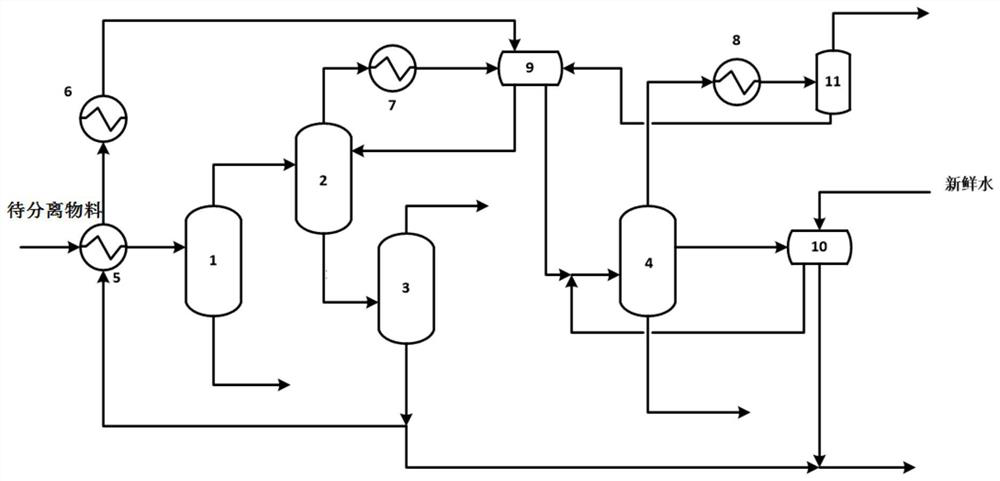

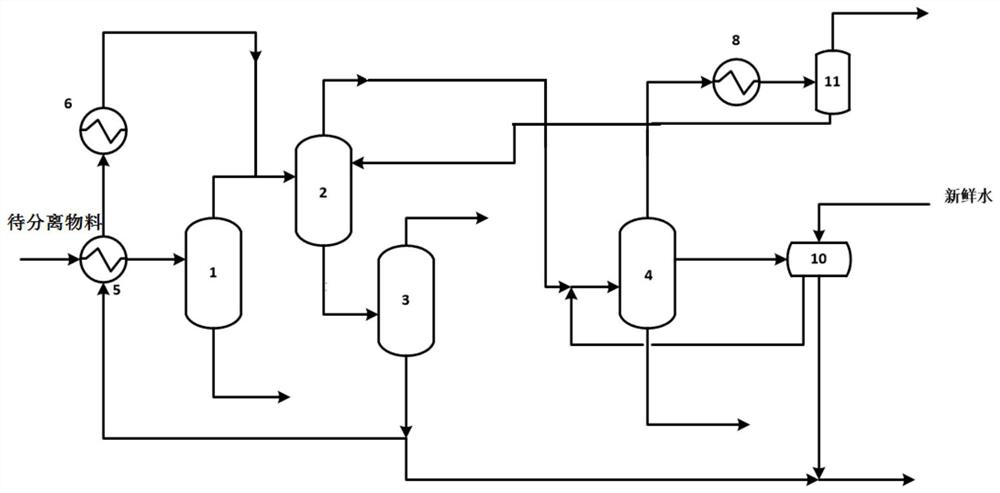

[0038]According to a preferred embodiment of the present invention, the conditions for rectification in the ethanol rectification tower 3 include: the temperature at the top of the tower is 30-78°C, the pressure at the top of the tower is 0.01-0.1MPa, the temperature at the bottom of the tower is 74-104°C, The pressure at the bottom of the tower is 0.04-0.13MPa, the number of plates is 29-40, and the reflux ratio is 10-20; more preferably, the temperature at the top of the tower is 60-78°C, the pressure at the top of the tower is 0.06-0.1MPa, and the temperature at the bottom of the tower is 94-104°C, the pressure at the bottom of the tower is 0.08-0.13MPa, the number of plates is 34-38, and the reflux ratio is 13-18.

[0039] According to a specific embodiment of the present invention, the second distillate can be condensed through the first condenser 7 (preferably condensed to 20-30°C), and then passed into the top separator 9 of the ethanol separation tower.

[0040] Accord...

specific Embodiment approach

[0057] According to a specific embodiment of the present invention, the method also includes cooling the heat-exchanged third residue with a cooler 6 (preferably cooled to 20-50° C.) and then sending it to the top separator 9 of the ethanol separation tower .

[0058] According to a preferred embodiment of the present invention, the conditions for distillation and separation in the acetic acid separation tower 1 include: the temperature at the top of the tower is 35-90°C, the pressure at the top of the tower is 0.01-0.11MPa, and the temperature at the bottom of the tower is 97-130°C. The bottom pressure is 0.06-0.16MPa, the number of trays is 16-27, and the reflux ratio is 2.5-5; more preferably, the temperature at the top of the tower is 75-85°C, the pressure at the top of the tower is 0.06-0.1MPa, and the temperature at the bottom of the tower is 115 -125°C, the pressure at the bottom of the tower is 0.1-0.15MPa, the number of trays is 20-24, and the reflux ratio is 3-5.

...

Embodiment 1

[0078] This embodiment is used to illustrate the separation method and device for ethanol and ethyl acetate provided by the present invention.

[0079] 1) if figure 1 As shown, the material to be separated containing ethanol, ethyl acetate and acetic acid (see Table 1 for specific composition) is preheated to 59 ° C through heat exchanger 5 and sent to acetic acid separation tower 1 for distillation and separation (see Table 2 for specific conditions) ), a first distillate is obtained at the top of the column, and a first residue mainly containing acetic acid and water is obtained at the bottom of the column.

[0080] 2) The first distillate is sent to the ethanol separation tower 2 for distillation and separation (see Table 2 for specific conditions), the second distillate is obtained at the top of the tower, and the second residue mainly containing ethanol and water is obtained at the bottom of the tower , the second residue is rectified in the ethanol rectification tower 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com