Leak sensor for side detection

A sensor and sensor layer technology, applied in the field of leak sensors, can solve problems such as inability to detect leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

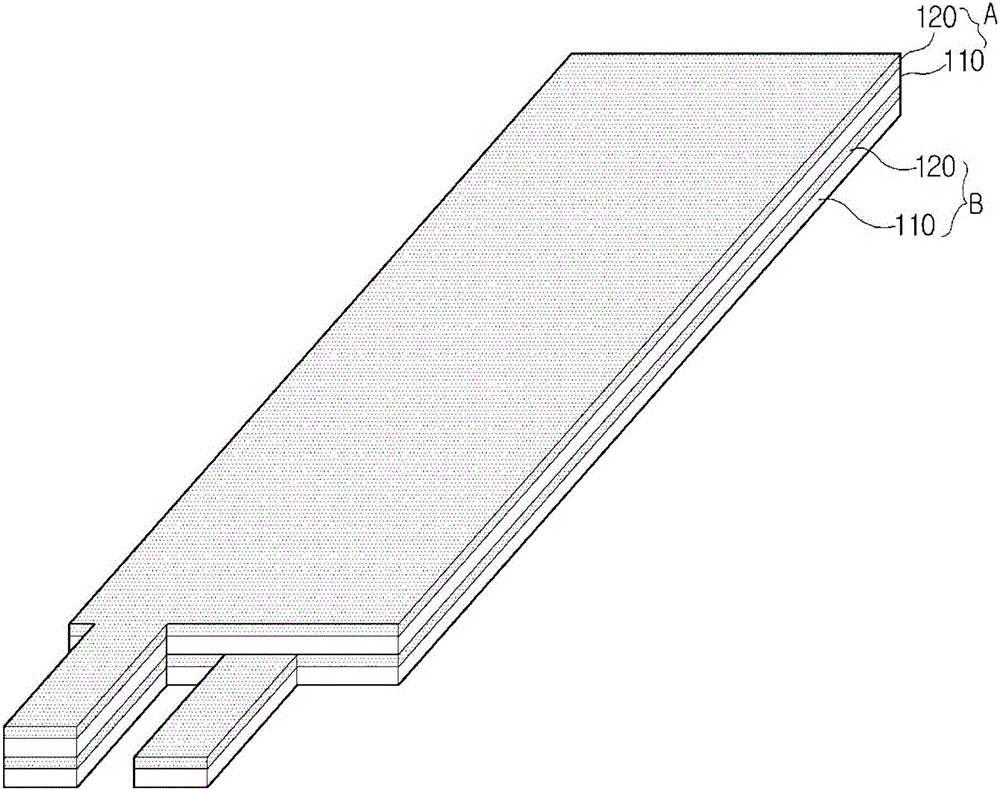

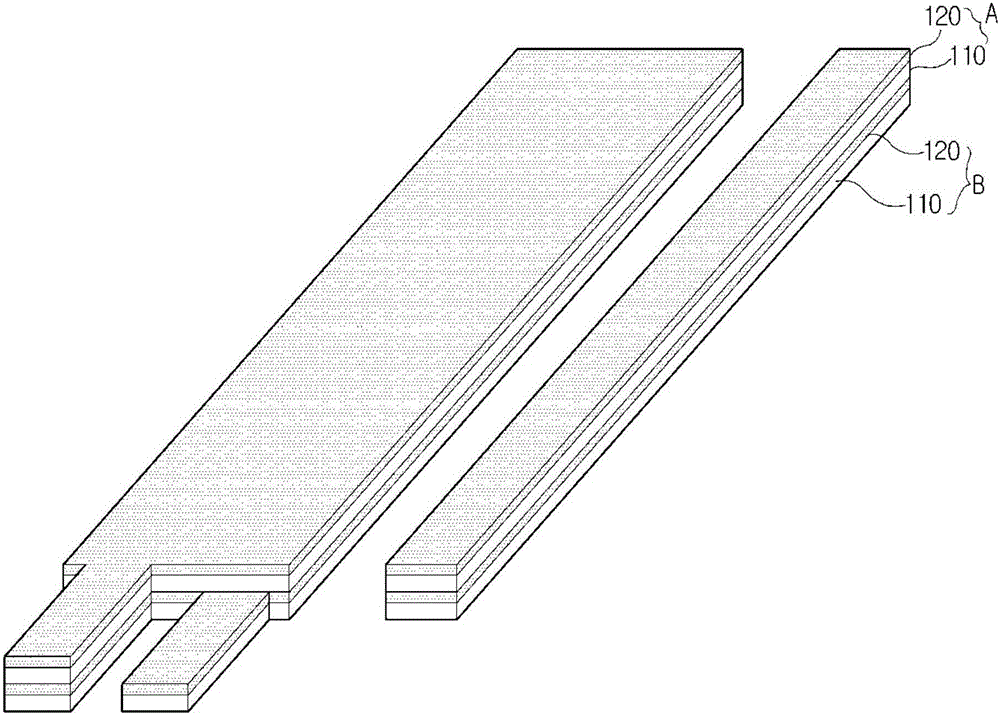

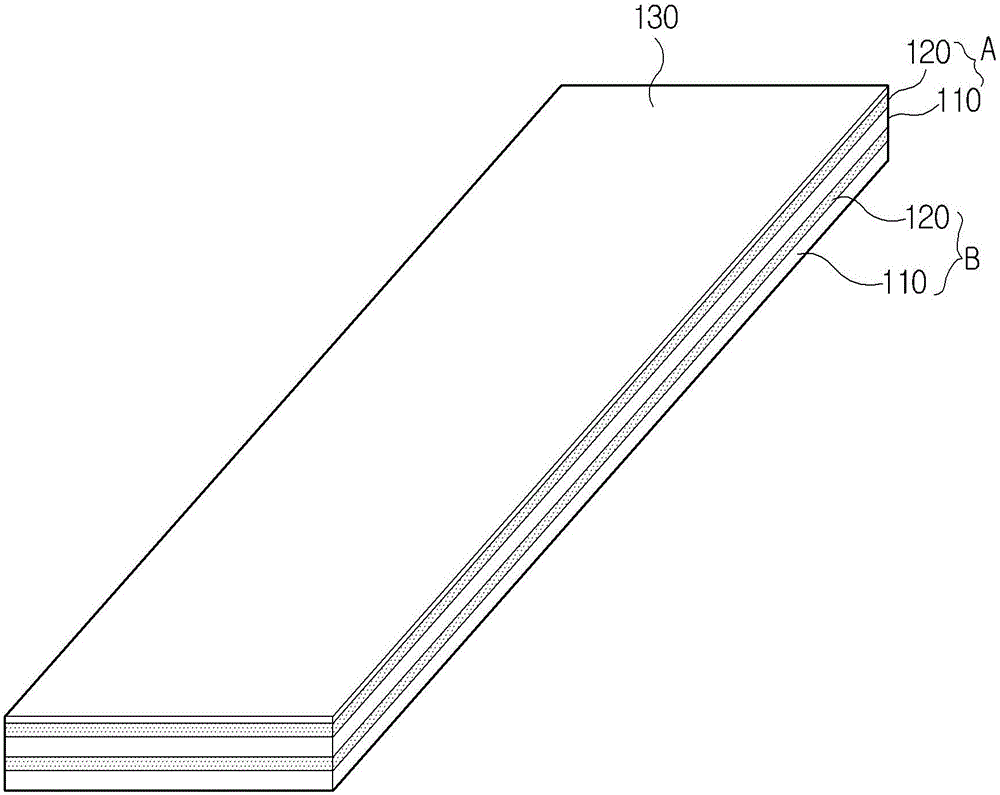

[0026] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0027] refer to figure 1 and figure 2 , The leak sensor for lateral detection according to the first embodiment of the present invention includes a base layer 110 having corrosion resistance to chemical agents and a sensor layer 120 also having corrosion resistance to chemical agents.

[0028] The base layer 110 is formed by immersing a plate-like structure in a resin solution (in particular, a fluorine-based resin solution) for a predetermined time. Here, the plate structure is a structure forming a frame of the base layer 110, and may be formed of mesh-like glass fibers. Alternatively, the base layer 110 may be formed as a plate-like structure formed of resin, particularly fluorine-based resin.

[0029] The sensor layer 120 includes a leak detection part having a predetermined area, which is formed by mixing a fluorine-based liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com