Weather-resistant fluorine coating, weather-resistant fluorine coat, photovoltaic adhesive film and preparation method thereof

A fluorine coating, weather-resistant technology, applied in coatings, photovoltaic power generation, polyurea/polyurethane coatings, etc., can solve the problems of chalking, cracking, and the coating is easy to lose light, and achieve better weather resistance and uniform coating thickness. , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

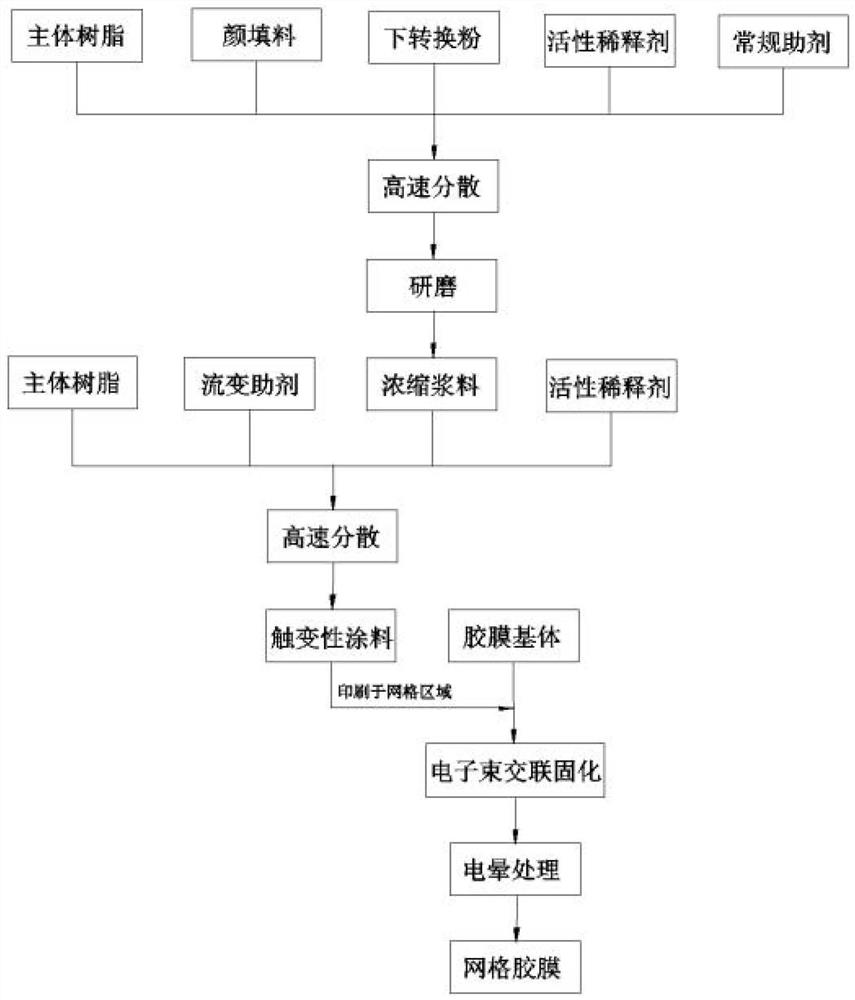

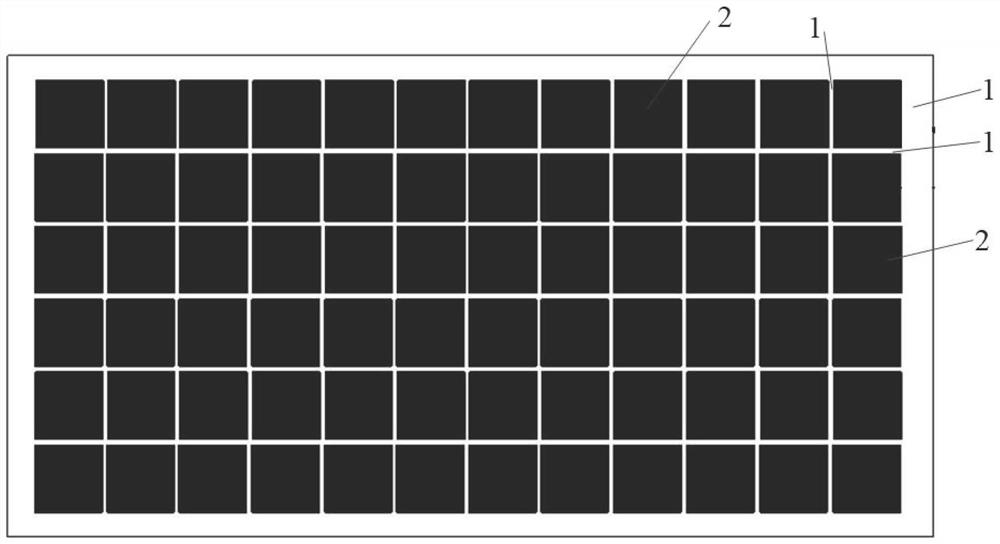

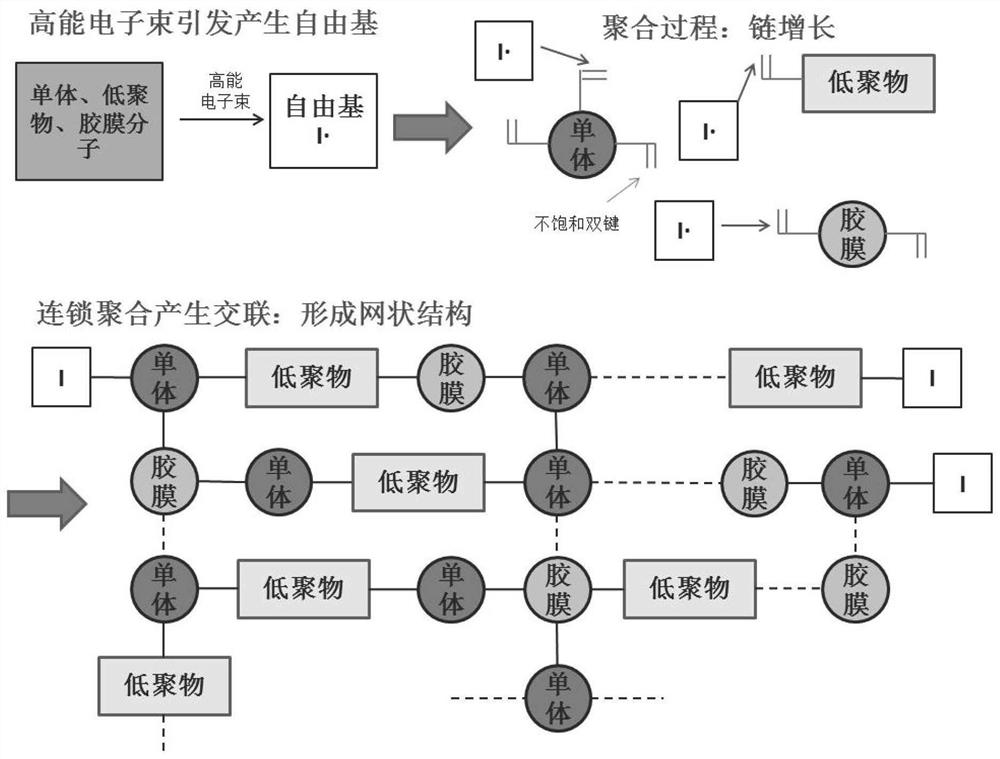

[0039] Optionally, the adhesive film base includes but not limited to transparent adhesive film, white adhesive film, black adhesive film, colored adhesive film, etc., the type of adhesive film is one of the upper layer adhesive film or the lower layer adhesive film, and its coating The printing surface is the side close to the cell, and the printing surface of the adhesive film is not embossed or the embossing depth is ≤0.5mm. further, see figure 1 , the invention provides a method for preparing a photovoltaic grid adhesive film, comprising: preparing an electron beam-cured weather-resistant fluorine coating; coating the weather-resistant fluorine coating on the printed grid area on the adhesive film substrate; electron beam crosslinking and curing; Corona treatment.

[0040] Optionally, the printing area on the adhesive film substrate needs to extend 1-3 mm to the battery sheet coverage area on the basis of the grid area.

[0041] Optionally, the method of applying the wea...

Embodiment 1

[0046] According to the raw material formula shown in Table 2, the fluorine coating was prepared, stirred and ground. Grinding stage: stirring speed is 1000 rpm, stirring time is 30min, grinding speed is 1000 rpm, flow rate is 800kg / h, grinding 3 times; secondary batching stage: 800 rpm, dispersion time is 90min, mixing material Temperature ≤ 60°C. Transfer the prepared white paint to a piece of transparent EVA adhesive film by screen printing, and carry out electron beam curing. The electron beam irradiation dose is 15kGy, and the corona intensity is 4.5kW, and then the photovoltaic grid adhesive film can be made.

[0047] The raw material formula of table 2 embodiment 1

[0048]

[0049]

Embodiment 2

[0051] According to the raw material formula shown in Table 3, the fluorine coating was prepared, stirred and ground. Grinding stage: stirring speed is 1000 rpm, stirring time is 30min, grinding speed is 1000 rpm, flow rate is 800kg / h, grinding 3 times; secondary batching stage: 800 rpm, dispersion time is 90min, mixing material Temperature ≤ 60°C. The prepared white paint was transferred to a transparent POE film by screen printing, and then cured by electron beam. The electron beam irradiation dose was 15kGy and the corona intensity was 5.0kW, and then the photovoltaic grid film could be made.

[0052] The raw material formula of table 3 embodiment 2

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com