Low-temperature-resistant fluororubber composition and application thereof

A technology of low temperature resistance and fluorine rubber, applied in the field of polymer rubber materials, can solve the problem that the low temperature resistance and chemical medium resistance of fluorine rubber composition need not be taken into account at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

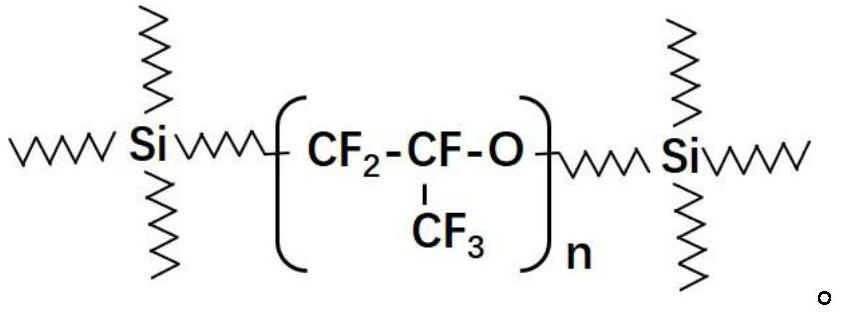

Method used

Image

Examples

Embodiment 1

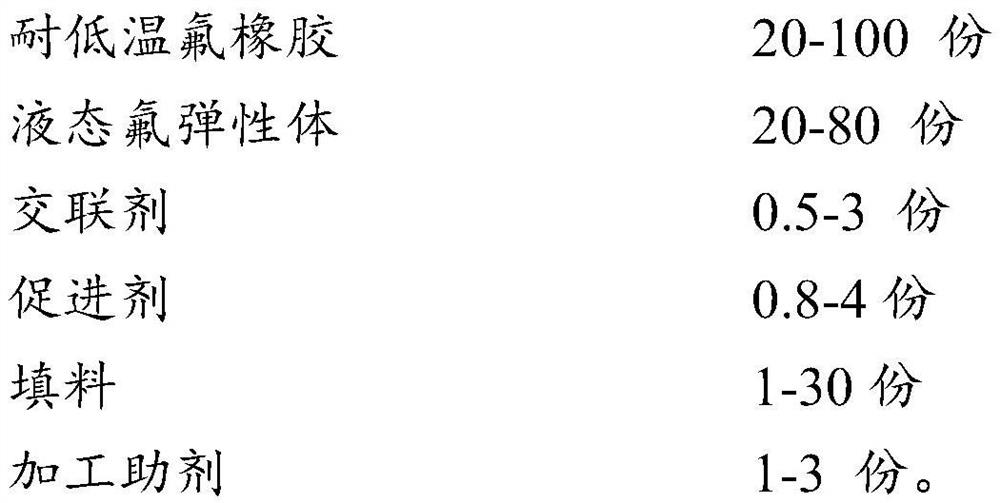

[0020] Embodiment 1 low temperature resistant fluororubber composition formula

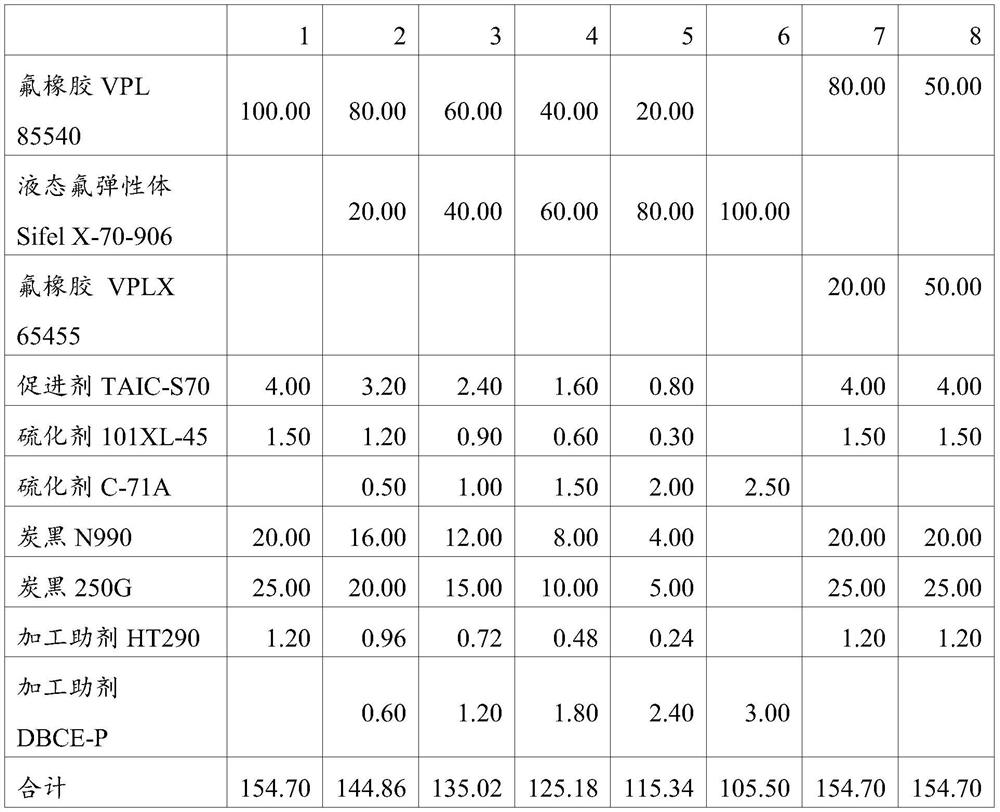

[0021] Table 1 shows the formulations of No. 1 to No. 8 fluororubber compositions, wherein, the detailed parts by weight of each component in the raw materials are shown in Table 1.

[0022] Table 1 No. 1-8 low-temperature fluororubber composition formula

[0023]

Embodiment 2

[0024] The performance test of embodiment 2 low temperature fluorine rubber composition

[0025] Weigh each component according to No. 1 to No. 8 formulations (parts by weight) in Example 1, wrap fluororubber and liquid fluoroelastomer on a double-roller open mill, and mix crosslinking agent, accelerator, carbon black And auxiliary materials such as processing aids are added to the open mill and mixed with fluororubber, and the roller temperature is lower than 80°C, and the mixture is evenly mixed and flakes are produced to obtain fluororubber compound. Under the condition of 180℃, 10 minutes of one-stage vulcanization, the mixed rubber is molded and vulcanized into a standard rubber test piece at 20MPa, and then second-stage vulcanized at 200℃ for 4 hours, and the fluororubber test piece is made according to the standard test sample. Sample and test, the performance test data results of No. 1-6 fluororubber compositions are shown in Table 2.

[0026] Among them, the test met...

Embodiment 3

[0038] Embodiment 3: Preparation of low temperature resistant fluororubber composition

[0039] (1) 50 parts by weight of fluororubber polymer Viton GLT600S and 50 parts by weight of liquid fluoroelastomer X-70-906 is masticated evenly on a double-roller mill and covered with rolls, and then 1 part by weight of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 1.25 parts by weight Parts of 1,6-bis-(tert-butylperoxycarboxy) hexane, 2 parts by weight of triallyl isocyanurate, 20 parts by weight of filler carbon black N990, 1 part by weight of processing The auxiliary agent HT290 is pre-mixed evenly, and gradually added to the open mill, and all the auxiliary materials are mixed with the fluororubber;

[0040] (2) After mixing the fluorine rubber with the auxiliary materials, cut the rubber mixture wrapped in rolls 5 times on the left and right sides, adjust the roller distance of the open mill to the minimum, roll or make triangular bags 10 times, and control the entire mixing tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com