High-strength high-toughness fluorine-containing polyurethane and preparation method thereof

A high-strength, high-toughness, polyurethane technology, applied in the field of high-strength, high-toughness fluorine-containing polyurethane and its preparation, can solve the problems of tensile strength and elongation at break to be improved, and achieve the goal of simple method, mild reaction conditions and great application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

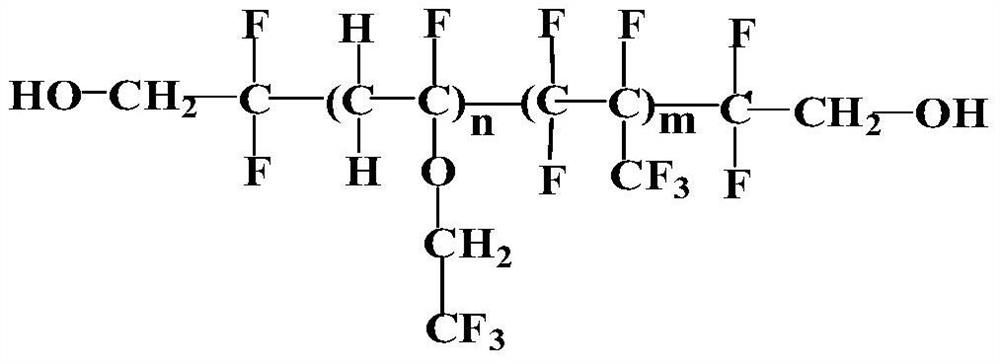

Method used

Image

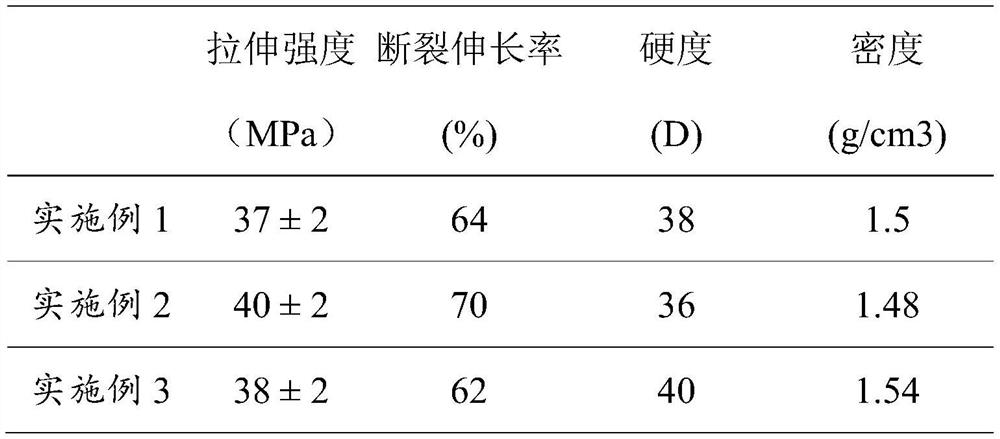

Examples

Embodiment 1

[0019] The preparation process of the high-strength and high-toughness fluorine-containing polyurethane in the present embodiment is as follows:

[0020] First, add 47g of polyoxypropylene glycol PPG with a molecular weight of 3000g / mol and 3g of hydroxyl-terminated liquid fluororubber with a molecular weight of 800g / mol into a four-necked flask, and vacuumize at 110°C for 2h to remove water.

[0021] Then, the temperature was lowered to 80°C, and 6g of isophorone diisocyanate IPDI, 0.1g of dibutyltin dilaurate, 20g of ethyl acetate and 10g of dimethyl sulfoxide were successively added to the four-necked flask, and nitrogen was blown. During the reaction, every Sampling was taken every half hour, and the change of the -NCO group peak was observed with an infrared spectrometer until the -NCO group no longer decreased, and an isocyanate-terminated fluorine-containing polyurethane prepolymer was obtained.

[0022] Then, 4.2 g of fluorodiol was dissolved in 2.1 g of dimethyl sulfo...

Embodiment 2

[0025] The preparation process of the high-strength and high-toughness fluorine-containing polyurethane in the present embodiment is as follows:

[0026] First, 45.5 g of polytetrahydrofuran ether glycol PTMG with a molecular weight of 2000 g / mol and 4.5 g of hydroxyl-terminated liquid fluororubber with a molecular weight of 800 g / mol were added to a four-necked flask, and the water was removed by vacuuming at 110°C for 2 hours.

[0027] Then, the temperature was lowered to 80°C, and 6g of hexamethylene diisocyanate HDI, 0.1g of dibutyltin dilaurate, 20g of ethyl acetate and 10g of dimethyl sulfoxide were successively added to the four-necked flask, and nitrogen was blown. During the reaction, every Sampling was taken every half hour, and the change of the -NCO group peak was observed with an infrared spectrometer until the -NCO group no longer decreased, and an isocyanate-terminated fluorine-containing polyurethane prepolymer was obtained.

[0028] Then, 1 g of 2,2,3,3-tetraf...

Embodiment 3

[0031] The preparation process of the high-strength and high-toughness fluorine-containing polyurethane in the present embodiment is as follows:

[0032] First, 47g of polyoxypropylene glycol PPG with a molecular weight of 3000g / mol and 3g of hydroxyl-terminated liquid fluororubber with a molecular weight of 800g / mol were added to a four-necked flask, and the water was removed by vacuuming at 110°C for 2h.

[0033] Then, the temperature was lowered to 80°C, and 8g perfluorotrimethylene diisocyanate, 0.1g dibutyltin dilaurate, 20g ethyl acetate and 10g dimethyl sulfoxide were successively added to the four-necked flask, and nitrogen was blown. During the reaction, every Sampling was taken every half hour, and the change of the -NCO group peak was observed with an infrared spectrometer until the -NCO group no longer decreased, and an isocyanate-terminated fluorine-containing polyurethane prepolymer was obtained.

[0034] Then, dissolve 1 g of fluorine-containing diamine in 0.5 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com