Preparation method of single-component silane-terminated liquid fluorine sealing rubber

A liquid fluororubber and sealant technology, applied in chemical instruments and methods, adhesives, adhesive additives, etc., can solve the problems of unenvironmental protection and high toxicity, and achieve the effect of good low temperature resistance, high cost performance and wide range of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

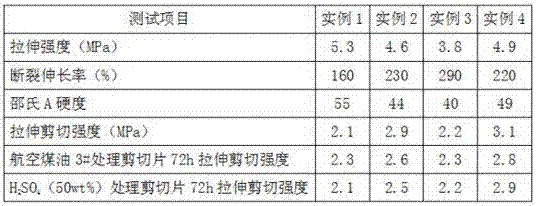

Examples

Embodiment 1

[0025] First, carboxyl-terminated liquid fluororubber (carboxyl-terminated poly(vinylidene fluoride-co-tetrafluoroethylene), carboxyl content of 1 wt%, number average molecular weight of 2000) was dissolved in the organic solvent tetrahydrofuran in a 10L glass reactor. The weight ratio of carboxyl-terminated poly(vinylidene fluoride-co-tetrafluoroethylene) to tetrahydrofuran was 1:2, and the dissolution process was carried out at room temperature 23°C; then, 3-(2,3-epoxy Propoxy)propyltrimethoxysilane, the carboxyl group in its carboxyl-terminated poly(vinylidene fluoride-co-tetrafluoroethylene) and the epoxy group in 3-(2,3-glycidoxy)propyltrimethoxysilane The molar ratio is 1:1; Then, add sodium hydroxide catalyst again, the dosage is 0.2wt% of carboxy-terminated poly(vinylidene fluoride-co-tetrafluoroethylene), stir under nitrogen condition, react 4h after stirring, react The temperature is controlled at 50°C; finally, to end the reaction, slowly add hydrochloric acid to th...

Embodiment 2

[0028]First, carboxyl-terminated liquid fluororubber (carboxyl-terminated poly(vinylidene fluoride-co-hexafluoropropylene), carboxyl content of 4 wt%, number average molecular weight of 8000) was dissolved in organic solvent trifluoroacetic acid in a 10L glass reactor , the weight ratio of carboxyl-terminated poly(vinylidene fluoride-co-hexafluoropropylene) to trifluoroacetic acid is 1:5, and the dissolution process is carried out at room temperature 23°C; then, add 2-(3, 4-epoxycyclohexyl)methyltrimethoxysilane, carboxyl group in carboxyl-terminated poly(vinylidene fluoride-co-hexafluoropropylene) and 2-(3,4-epoxycyclohexyl)methyltrimethoxysilane The molar ratio of epoxy group in oxysilane is 1:3; Then, add potassium hydroxide catalyst again, consumption is the 0.2wt% of carboxy-terminated poly(vinylidene fluoride-co-hexafluoropropylene), stir under nitrogen condition React for 8 hours, and the reaction temperature is controlled at 120°C; finally, to end the reaction, slowly ...

Embodiment 3

[0031] First, carboxyl-terminated liquid fluororubber (carboxyl-terminated poly(tetrafluoroethylene-co-hexafluoropropylene), carboxyl content of 3 wt%, number average molecular weight of 6000) was dissolved in organic solvent acetone in a 10L glass reactor. The weight ratio of carboxyl-terminated poly(tetrafluoroethylene-co-hexafluoropropylene) to acetone was 1:3, and the dissolution process was carried out at room temperature 23°C; then, 2-(3,4-epoxy Cyclohexyl)methyltriethoxysilane, carboxyl group in carboxyl-terminated poly(tetrafluoroethylene-co-hexafluoropropylene) and 2-(3,4-epoxycyclohexyl)methyltriethoxy The molar ratio of the epoxy group in the silane is 1:2; Then, add sodium ethylate catalyst again, consumption is the 0.2wt% of carboxyl-terminated poly(tetrafluoroethylene-co-hexafluoropropylene), stir reaction 6h under nitrogen condition, The reaction temperature is controlled at 100°C; finally, to end the reaction, slowly add hydrochloric acid to the reaction system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com