Preparation method and solidification method of silicyl-terminated liquid fluorine polymer

A silyl-terminated, liquid fluorine technology, which is applied in the preparation and curing of silyl-terminated liquid fluoropolymers, can solve problems that affect the service life of the product and cannot meet the requirements of curing and use, and achieve good chemical resistance and low cost. Inexpensive, simple and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 8g of carboxyl-terminated liquid fluoropolymer (vinylidene fluoride-hexafluoropropylene copolymer, carboxyl mass percentage content 2.14%, number average molecular weight Mn=6.2×10 3 , weight average molecular weight Mw=11.7×10 3 , the following examples are not described, all of this substance) was dissolved in 50g of tetrahydrofuran, added to a 250mL four-neck flask, and pentafluorophenol (PFP, 0.81 g, 4.37 mmol), dicyclohexylcarbodiimide (DCC , 1.12 g, 5.47 mmol), 4-dimethylaminopyridine (DMAP, 0.026 g, 0.21 mmol), p-toluenesulfonic acid (TsOH, 0.041 g, 0.21 mmol), at 25 o The reaction was stirred at C for 24h. There will be white suspended matter in the system, filter the product system to remove the white solid matter, drop the filtrate into petroleum ether, and purify the product. The solvent was evaporated by rotary evaporation, and the product was dried under vacuum at 60° C. for 24 h. 7.03 g of a yellow viscous liquid were obtained. Infrared analysis showed...

Embodiment 2

[0022] 8g of carboxyl-terminated liquid fluoropolymer (vinylidene fluoride-tetrafluoroethylene-hexafluoropropylene copolymer, the mass percentage of carboxyl group is 2.21%, the number average molecular weight Mn=2.2×10 3 , weight average molecular weight Mw=3.6×10 3 ) was dissolved in 50g tetrahydrofuran / dichloromethane mixed solution, added to a 250mL four-necked flask, and pentafluorophenol (PFP, 0.81 g, 4.37 mmol), dicyclohexylcarbodiimide (DCC, 1.12 g, 5.47 mmol), 4-dimethylaminopyridine (DMAP, 0.026 g, 0.21 mmol), p-toluenesulfonic acid (TsOH, 0.041 g, 0.21 mmol), at 25 o The reaction was stirred at C for 8h. There will be white suspended matter in the system, filter the product system to remove the white solid matter, drop the filtrate into petroleum ether, and purify the product. The solvent was evaporated by rotary evaporation, and the product was dried under vacuum at 60° C. for 24 h. 7.46 g of a yellow viscous liquid were obtained. Infrared analysis showed that ...

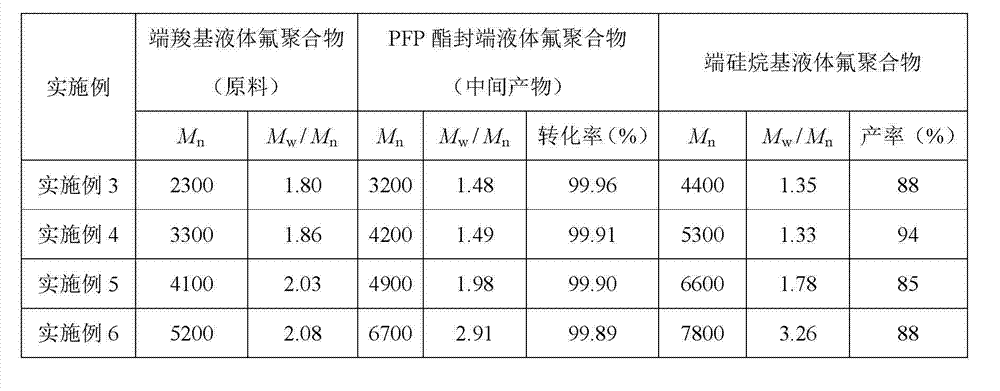

Embodiment 3~6

[0025] The specific implementation method is the same as in Example 1, except that the molecular weight of the raw material changes, and the specific changes are as shown in the table, and the obtained results are also listed in the table. where: M n and M w / M n is the number-average molecular weight of the polymer tested by GPC; the conversion rate of the intermediate product is calculated by dividing the carboxyl content of the product after the reaction by the carboxyl content in the raw material.

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com