High-corrosion-resistance aluminum alloy composite and preparation method thereof

A technology of high corrosion resistance and composite materials, which is applied in the direction of coating, pretreatment surface, and device for coating liquid on the surface, etc. Combined with problems such as insufficient stability, the effects of avoiding loose material structure, excellent high temperature resistance and chemical stability, and preventing oxidation are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

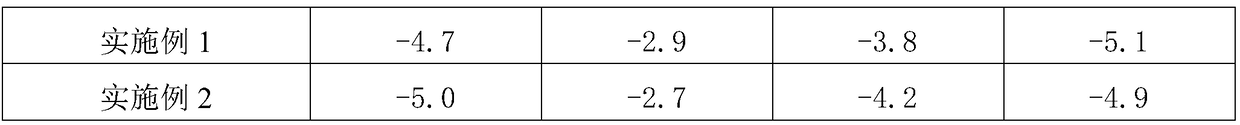

Embodiment 1

[0057] A high corrosion-resistant aluminum alloy composite material, comprising an aluminum alloy composite material and a corrosion-resistant coating, the corrosion-resistant coating being a carborane-liquid fluoropolymer coating;

[0058] The aluminum alloy composite material includes a matrix aluminum alloy and a reinforcing phase distributed in the matrix aluminum alloy;

[0059] The chemical composition of the base aluminum alloy includes:

[0060] 1.5 wt% Mg;

[0061] 1.0wt% Si;

[0062] 0.5 wt% Co;

[0063] 0.8 wt% Mo;

[0064] 0.3 wt% RE;

[0065] 0.5 wt% Zn;

[0066] 0.03 wt% Cr;

[0067] The balance is aluminum;

[0068] The reinforcing phase is SiO 2 coated graphene.

[0069] The base aluminum alloy and SiO 2 The weight ratio of coated graphene is 1:0.01.

[0070] The carborane-liquid fluoropolymer is prepared by the following method: the high-pressure reactor is ventilated with nitrogen to replace the atmosphere, and then sequentially added a tetrahydrof...

Embodiment 2

[0076] A high corrosion-resistant aluminum alloy composite material, comprising an aluminum alloy composite material and a corrosion-resistant coating, the corrosion-resistant coating being a carborane-liquid fluoropolymer coating;

[0077] The aluminum alloy composite material includes a matrix aluminum alloy and a reinforcing phase distributed in the matrix aluminum alloy;

[0078] The chemical composition of the base aluminum alloy includes:

[0079] 2 wt% of Mg;

[0080] 1.0wt% Si;

[0081] 0.8 wt% Co;

[0082] 0.5 wt% Mo;

[0083] 0.3 wt% RE;

[0084] 0.2 wt% Zn;

[0085] 0.05 wt% Cr;

[0086] The balance is aluminum;

[0087] The reinforcing phase is SiO 2 coated graphene. The base aluminum alloy and SiO 2 The weight ratio of coated graphene is 1:0.05.

[0088] The carborane-liquid fluoropolymer is prepared by the following method: the high-pressure reactor is ventilated with nitrogen to replace the atmosphere, and then sequentially added a tetrahydrofuran sol...

Embodiment 3

[0095] A method for preparing a highly corrosion-resistant aluminum alloy composite material, comprising the following steps:

[0096] (1) SiO 2 Add the coated graphene into the solvent for ultrasonic dispersion for 10-20 minutes, then add aluminum alloy powder, stir and mix evenly, ultrasonically disperse for 10-20 minutes, and obtain the mixed powder after removing the solvent;

[0097] (2) Put the mixed powder prepared in step 1 into a VC high-efficiency mixer, and mix for 60 minutes under the condition of a rotating speed of 120r / min;

[0098] (3) Place the mixed powder obtained in step 2 in a stirring ball mill, fill it with liquid nitrogen, and start ball milling when all the balls are submerged in liquid nitrogen, the ball-to-material ratio is 30:1, and ball mill for 4 to 6 hours;

[0099] (4) Put the composite powder uniformly mixed by ball mill into the prefabricated graphite mold, and carry out surface activation treatment in the plasma activation sintering furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com