High-temperature-resistant antibacterial cable

An antibacterial and high temperature resistant technology, applied in the field of cables, can solve the problems of people's life and property safety, unsatisfactory antibacterial performance, easy to be eroded by bacteria, etc., to improve high temperature resistance, good compatibility, overcome the Poor workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

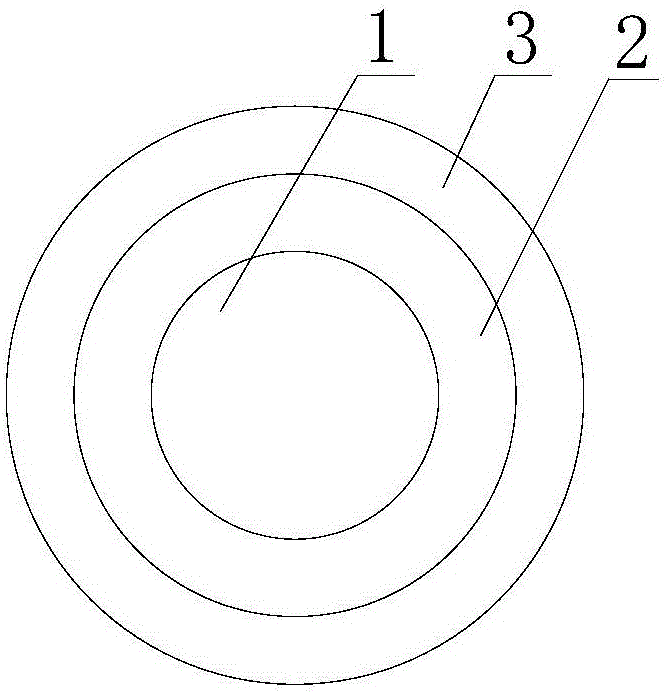

[0019] figure 1 It is the structural representation of the high temperature resistant antibacterial cable of the present invention; figure 1 , a kind of high temperature resistant antibacterial cable that the present invention proposes, comprises conductor 1, is covered with fluoroplastic insulation layer 2 outside described conductor 1, is covered with sheath 3 outside described fluoroplastic insulation layer 2; Wherein, The sheath 3 is prepared from a silicone rubber composite material, and the raw materials of the silicone rubber composite material include by weight: 85 parts of silicone rubber, 235 parts of fluororubber, 20 parts of EPDM rubber, ethylene-methacrylic acid 2 parts of copolymer, 12 parts of epoxy resin, 0.2 parts of zinc oxide, 1.2 parts of stearic acid, 0.5 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane, fumed white 25 parts of carbon black, 2 parts of alumina, 15 parts of talc powder, 3 parts of quartz powder, 15 parts of wollastonite, 1 part of...

Embodiment 2

[0021] refer to figure 1 , a kind of high temperature resistant antibacterial cable that the present invention proposes, comprises conductor 1, is covered with fluoroplastic insulation layer 2 outside described conductor 1, is covered with sheath 3 outside described fluoroplastic insulation layer 2; Wherein, The sheath 3 is prepared from a silicone rubber composite material, and the raw materials of the silicone rubber composite material include by weight: 70 parts of silicone rubber, 2315 parts of fluororubber, 15 parts of EPDM rubber, ethylene-methacrylic acid 8 parts of copolymer, 3 parts of epoxy resin, 1 part of zinc oxide, 0.3 parts of stearic acid, 2 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane, vapor phase whitening 10 parts of carbon black, 12 parts of alumina, 2 parts of talc powder, 12 parts of quartz powder, 4 parts of wollastonite, 3 parts of nano copper, 2 parts of nano cerium oxide, 20 parts of modified nano silicon dioxide, hexamethyl di 2 parts o...

Embodiment 3

[0023] refer to figure 1 , a kind of high temperature resistant antibacterial cable that the present invention proposes, comprises conductor 1, is covered with fluoroplastic insulation layer 2 outside described conductor 1, is covered with sheath 3 outside described fluoroplastic insulation layer 2; Wherein, The sheath 3 is prepared from a silicone rubber composite material, and the raw materials of the silicone rubber composite material include by weight: 80 parts of silicone rubber, 237 parts of fluororubber, 20 parts of EPDM rubber, ethylene-methacrylic acid 4.5 parts of copolymer, 14 parts of epoxy resin, 0.5 parts of zinc oxide, 1 part of stearic acid, 1.1 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane, fumed white 22 parts of carbon black, 4 parts of alumina, 12 parts of talc powder, 6 parts of quartz powder, 10 parts of wollastonite, 1.6 parts of nano copper, 4 parts of nano cerium oxide, 10 parts of modified nano silicon dioxide, hexamethyl di 6 parts of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com