High-corrosion-resistance aluminum alloy composite material and preparation method thereof

A high corrosion resistance, composite material technology, applied in anti-corrosion coatings, fire-resistant coatings, polyurea/polyurethane coatings, etc., can solve the problems of limited use, lack of corrosion resistance of aluminum alloys, etc., to prevent oxidation, excellent high temperature resistance and the effect of improving chemical stability and chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

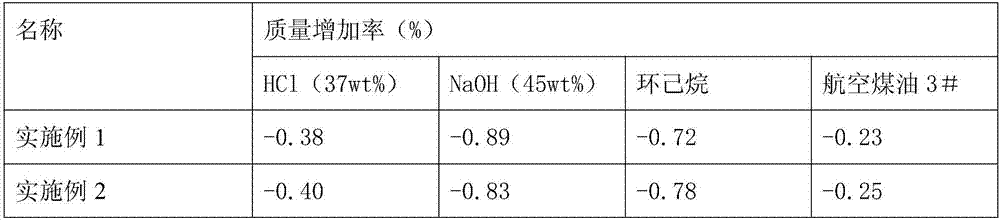

Examples

Embodiment 1

[0044] A high-corrosion-resistant aluminum alloy composite material includes an aluminum alloy composite material and a corrosion-resistant coating, and the corrosion-resistant coating is a carborane-liquid fluoropolymer coating.

[0045] The carborane-liquid fluoropolymer is prepared by the following method: the high-pressure reactor is ventilated with nitrogen to replace the atmosphere, and then the carboxyl-terminated liquid fluoropolymer (vinylidene fluoride-tetrafluoroethylene-hexafluoropropylene) is sequentially added under the condition of nitrogen. Copolymer, carboxyl mass percentage content is 2.01%, number average molecular weight Mn=3500, weight average molecular weight Mw=1.6×10 3 ) tetrahydrofuran solution, 1,7-dimethylolcarborane, dicyclohexylcarbodiimide, 4-dimethylaminopyridine, p-toluenesulfonic acid, stirred and reacted at 70°C and 1.0Mpa for 48h , cooled to room temperature, discharging, filtering, and the filtrate was separated by column chromatography, was...

Embodiment 2

[0059] A high-corrosion-resistant aluminum alloy composite material includes an aluminum alloy composite material and a corrosion-resistant coating, and the corrosion-resistant coating is a carborane-liquid fluoropolymer coating.

[0060] The carborane-liquid fluoropolymer is prepared by the following method: the high-pressure reactor is ventilated with nitrogen to replace the atmosphere, and then the carboxyl-terminated liquid fluoropolymer (vinylidene fluoride-tetrafluoroethylene-hexafluoropropylene) is sequentially added under the condition of nitrogen. Copolymer, carboxyl mass percentage content is 2.01%, number average molecular weight Mn=3500, weight average molecular weight Mw=1.6×10 3 ) tetrahydrofuran solution, 1,7-dimethylolcarborane, dicyclohexylcarbodiimide, 4-dimethylaminopyridine, p-toluenesulfonic acid, stirred and reacted at 70°C and 1.0Mpa for 48h , cooled to room temperature, discharging, filtering, and the filtrate was separated by column chromatography, was...

Embodiment 3

[0073] A method for preparing a highly corrosion-resistant aluminum alloy composite material, comprising the following steps:

[0074] (1) Dry the dicarbo-closed-dodecacarborane powder and the raw material powders of aluminum alloy, then put them into a "V" type powder mixer, and mix them at a speed of 35r / min 36h;

[0075] (2) Put the mixed powder obtained in step 1 into a VC high-efficiency mixer, and mix for 60 minutes under the condition of a rotating speed of 120r / min;

[0076] (3) Place the mixed powder obtained in step 1 in a stirring ball mill, fill it with liquid nitrogen, and start ball milling when all the balls are submerged in liquid nitrogen, the ball-to-material ratio is 30:1, and ball mill for 4 to 6 hours;

[0077] (4) Put the composite powder uniformly mixed by ball mill into the prefabricated graphite mold, and carry out surface activation treatment in the plasma activation sintering furnace, the loading time is 3-5min, the voltage is 30kV, and the current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com