Composite nanoparticles as well as preparation method and application thereof

A composite nanoparticle and nanoparticle technology, applied in the field of tumor radiation therapy sensitizing drugs, can solve the problem that the requirements of photothermal therapy cannot be well met, the preparation and functionalization conditions are harsh, and the morphology of nano gold is prone to change, etc. It can improve the hypoxic microenvironment of tumors, facilitate large-scale industrial production, and achieve the effect of large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of composite nano particle, its preparation method comprises the following steps:

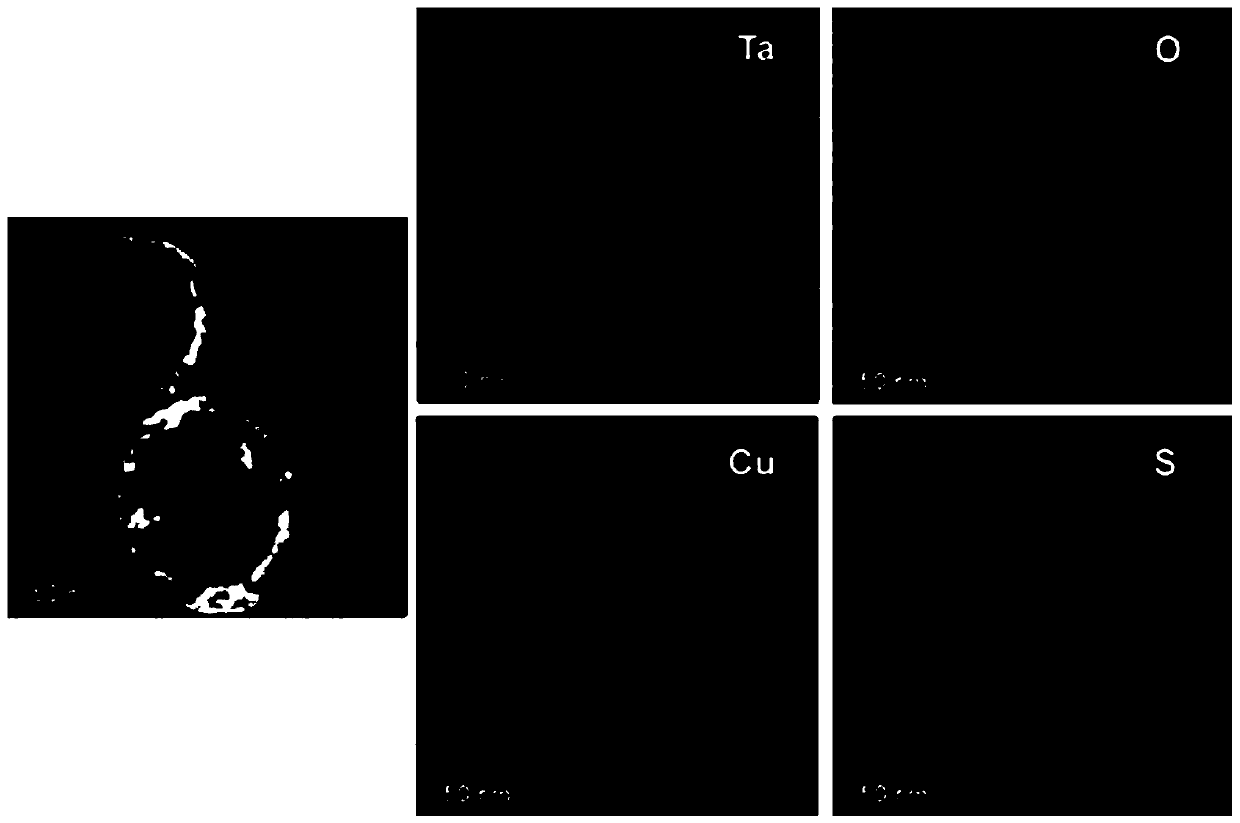

[0043] 1) Disperse 40 μL of tantalum ethanol in 800 μL of absolute ethanol to prepare a tantalum-containing mother solution, and then add the tantalum-containing mother solution dropwise into the ethanol solution (1 mL of absolute ethanol + 10 mL of deionized water) for 2 minutes. Stir at room temperature for 10 minutes, then centrifuge, and wash the centrifuged solid product with deionized water to obtain hollow mesoporous tantalum oxide nanoparticles (HMT);

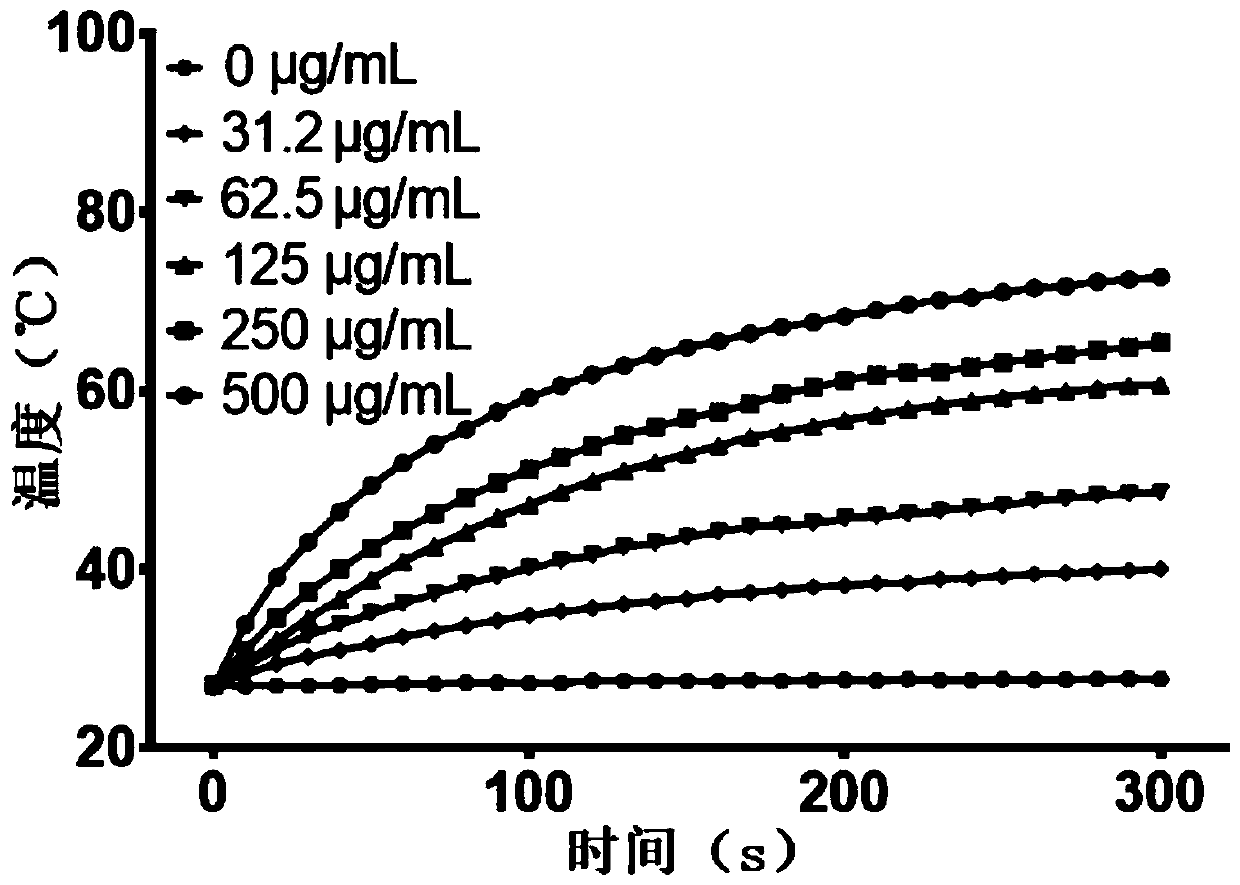

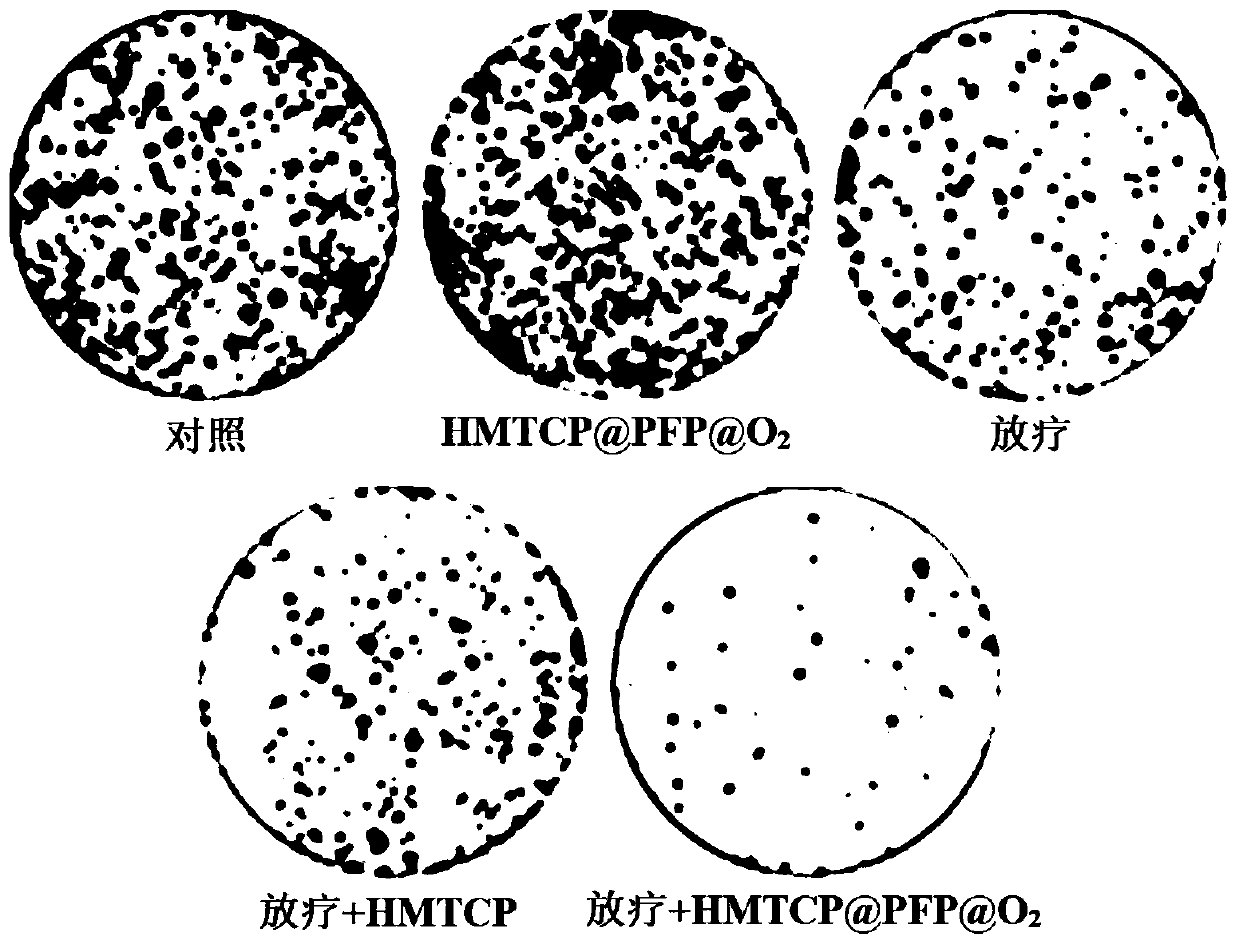

[0044] 2) Disperse 10 mg of hollow mesoporous tantalum oxide nanoparticles in 10 mL of deionized water, and then add 50 mg of CuCl 2 2H 2 O, stirred at room temperature for 6h, then added 100mg of polyvinylpyrrolidone with a number average molecular weight of 1000g / mol, stirred at room temperature for 1h, then added 50mg of Na 2 S·9H 2 O, heated to 80°C and stirred for 10 minutes, then stopped heating, continued to stir ...

Embodiment 2

[0058] A kind of composite nano particle, its preparation method comprises the following steps:

[0059] 1) Disperse 40 μL of tantalum ethanol in 800 μL of absolute ethanol to prepare a tantalum-containing mother solution, and then add the tantalum-containing mother solution dropwise into the ethanol solution (2 mL of absolute ethanol + 9 mL of deionized water) for 2 minutes. Stir at room temperature for 10 min, then centrifuge, and wash the centrifuged solid product with deionized water to obtain hollow mesoporous tantalum oxide nanoparticles (HMT).

[0060] 2) Disperse 10 mg of hollow mesoporous tantalum oxide nanoparticles in 10 mL of deionized water, and then add 20 mg of CuCl 2 2H 2 O, stirred at room temperature for 6h, then added 100mg of polyvinylpyrrolidone with a number average molecular weight of 40000g / mol, stirred at room temperature for 1h, then added 20mg of Na 2 S·9H 2 O, heated to 80°C and stirred for 10 minutes, then stopped heating, continued to stir for ...

Embodiment 3

[0068] A kind of composite nano particle, its preparation method comprises the following steps:

[0069] 1) Disperse 40 μL of tantalum ethanol in 800 μL of absolute ethanol to prepare a tantalum-containing mother solution, and then add the tantalum-containing mother solution dropwise into the ethanol solution (1 mL of absolute ethanol + 10 mL of deionized water) for 2 minutes. Stir at room temperature for 10 min, then centrifuge, and wash the centrifuged solid product with deionized water to obtain hollow mesoporous tantalum oxide nanoparticles (HMT).

[0070] 2) Disperse 10 mg of hollow mesoporous tantalum oxide nanoparticles in 10 mL of deionized water, and then add 50 mg of CuCl 2 2H 2 O, stirred at room temperature for 6h, then added 100mg of polyvinylpyrrolidone with a number average molecular weight of 40000g / mol, stirred at room temperature for 1h, then added 50mg of Na 2 S·9H 2 O, heated to 60°C and stirred for 10 minutes, then stopped heating, continued to stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com