High-temperature-resistant composite release film

A release film and high-temperature-resistant technology, which is applied in the field of film materials, can solve the problems of high cost, expensive raw materials, and low hygroscopicity of fluororesin release films, and achieve excellent anti-sticking and isolation effects, compact structure and easy peeling, high temperature Dimensional stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

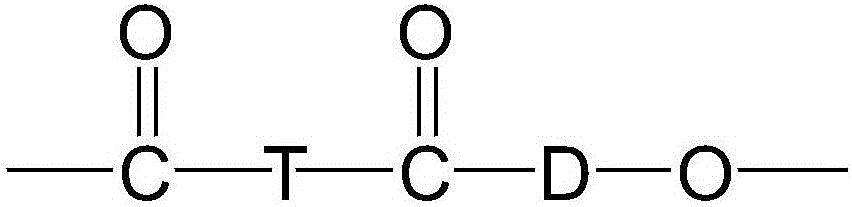

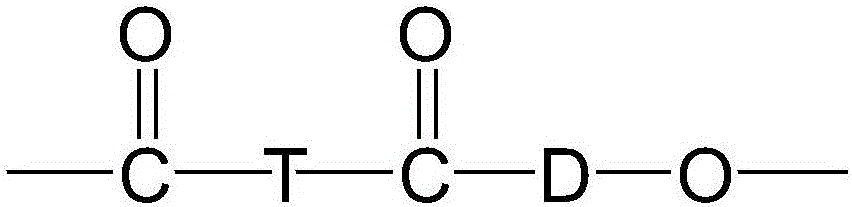

Method used

Image

Examples

Embodiment 1

[0028] Get 18 parts of silicone elastomer emulsion DC7935 (commercially available), 2 parts of crosslinking agent DC7975 (commercially available), 110 parts of deionized water; the above materials are dispersed evenly by a high-shear emulsifier to obtain a solid content of 5%. silicone elastomer adhesives.

[0029] The release layer is made of PET and polycarbonate by co-extrusion process to form a film.

[0030] The high-temperature resin film layer is made of ethylene-tetrafluoroethylene copolymer material (the molar content of tetrafluoroethylene monomer is 51%) through T-die method.

[0031] The release layer and the high-temperature resin film layer are bonded and compounded by silicone elastomer adhesive. The thickness of the adhesive layer was 0.05 μm.

Embodiment 2

[0033] Take 27 parts of silicone elastomer emulsion DC7935 (commercially available), 2 parts of crosslinking agent DC7975 (commercially available), 110 parts of deionized water; the above materials are dispersed evenly by a high-shear emulsifier to obtain a solid content of 8%. silicone elastomer adhesives.

[0034] The release layer is made of polyethylene naphthalate and polycarbonate and extruded into a film by co-extrusion process.

[0035] The high-temperature resin film layer is made of ethylene-tetrafluoroethylene copolymer material (the molar content of tetrafluoroethylene monomer is 55%) through T-die method.

[0036] The release layer and the high-temperature resin film layer are bonded and compounded by silicone elastomer adhesive. The thickness of the adhesive layer was 0.8 μm.

Embodiment 3

[0038] Get 38 parts of silicone elastomer emulsion DC7935 (commercially available), 3 parts of crosslinking agent DC7975 (commercially available), 110 parts of deionized water; the above materials are dispersed evenly by a high-shear emulsifier to obtain a solid content of 10%. silicone elastomer adhesives.

[0039] The release layer is extruded into a film by co-extrusion process of PET and polyethylene.

[0040] The high-temperature resin film layer is made of ethylene-tetrafluoroethylene copolymer (the molar content of the tetrafluoroethylene monomer is 60%) through a T-die method.

[0041] The release layer and the high-temperature resin film layer are bonded and compounded by silicone elastomer adhesive. The thickness of the adhesive layer was 1 μm.

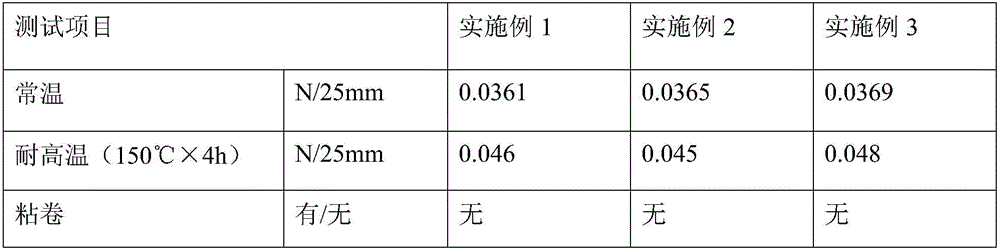

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com