Organic silicon releasing coating mixture used in coating method with high solid content resolvent

A technology of anti-adhesive coatings and mixtures, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., and can solve problems such as unsatisfactory consumers and poor wetting properties of coating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

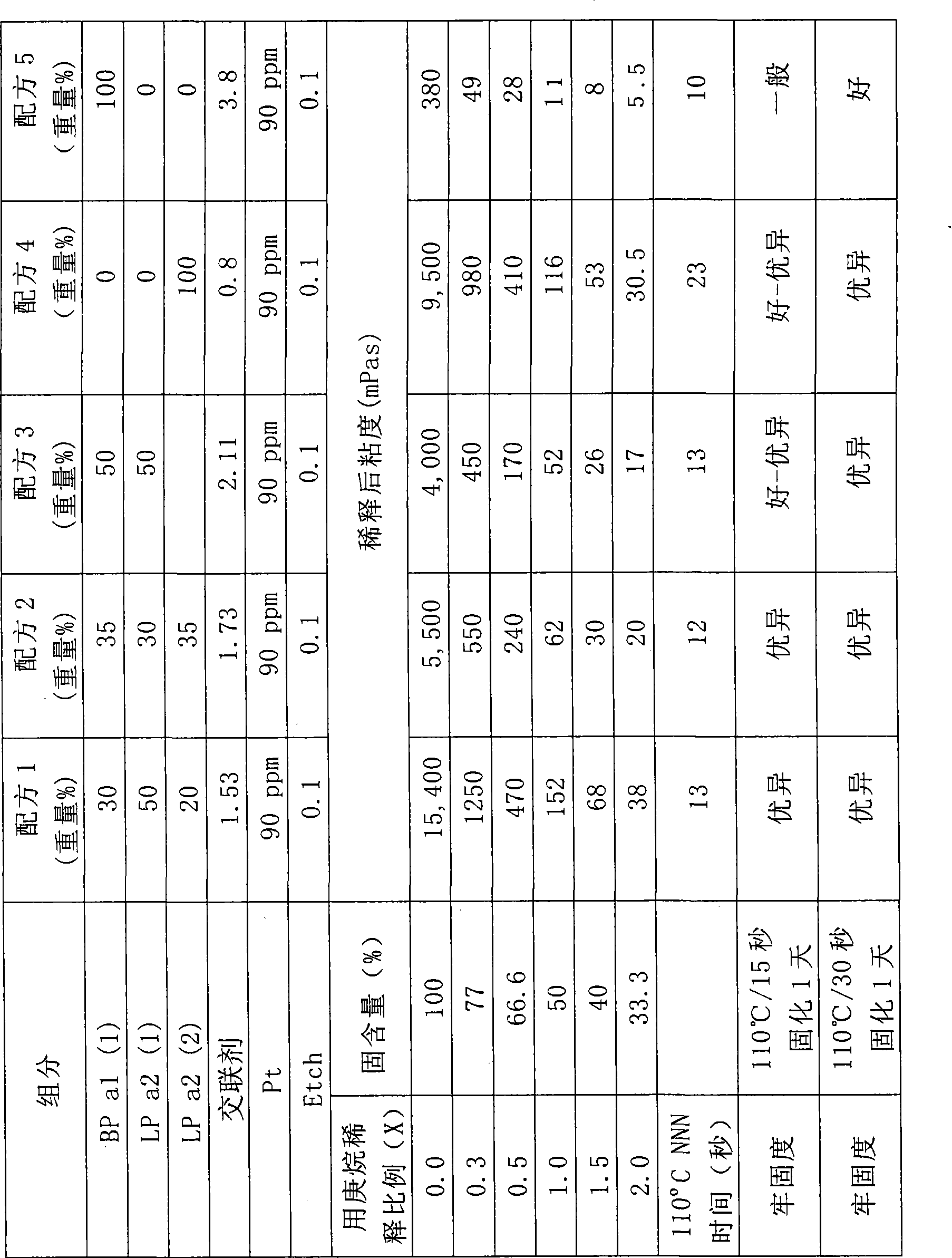

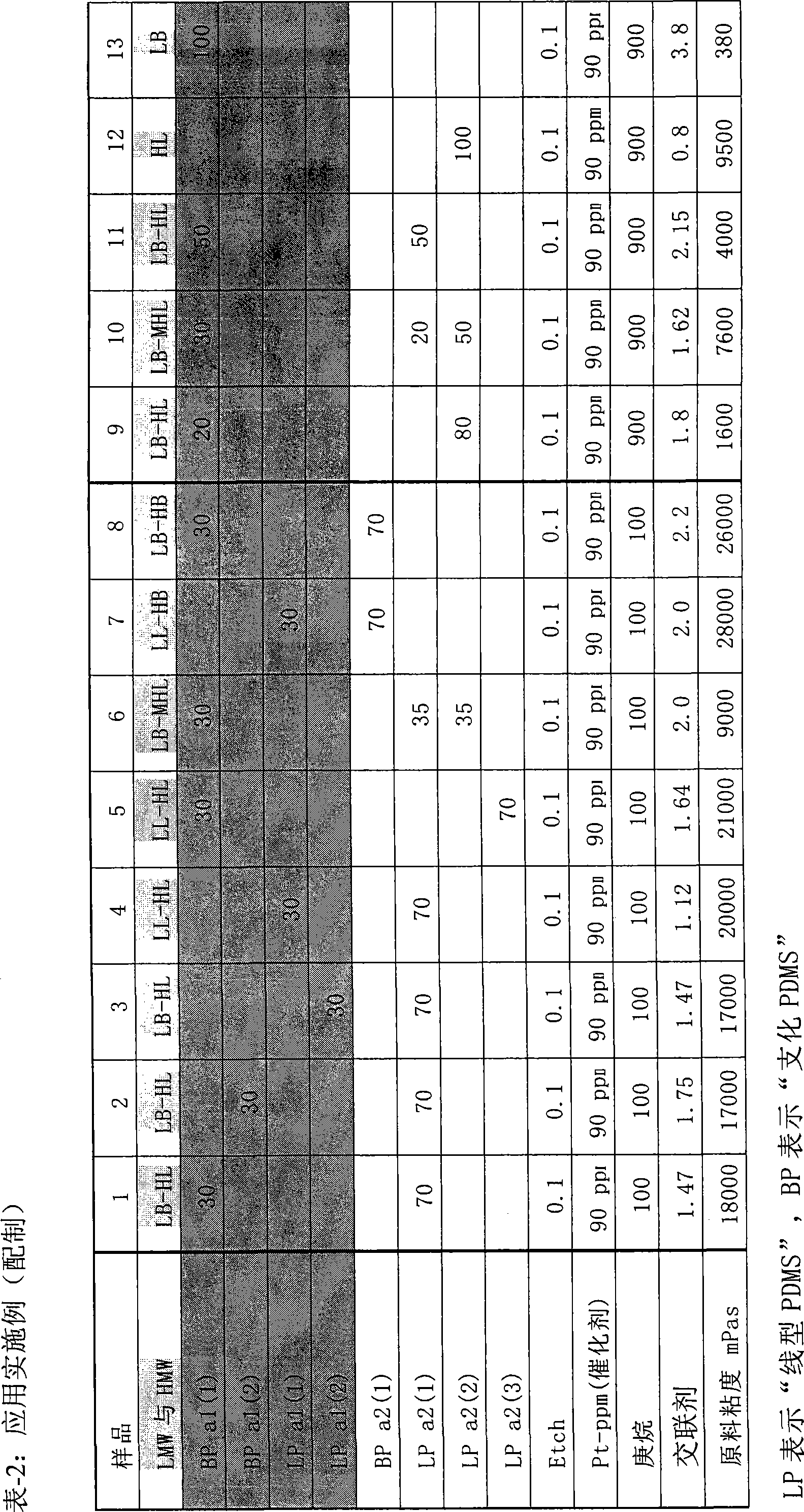

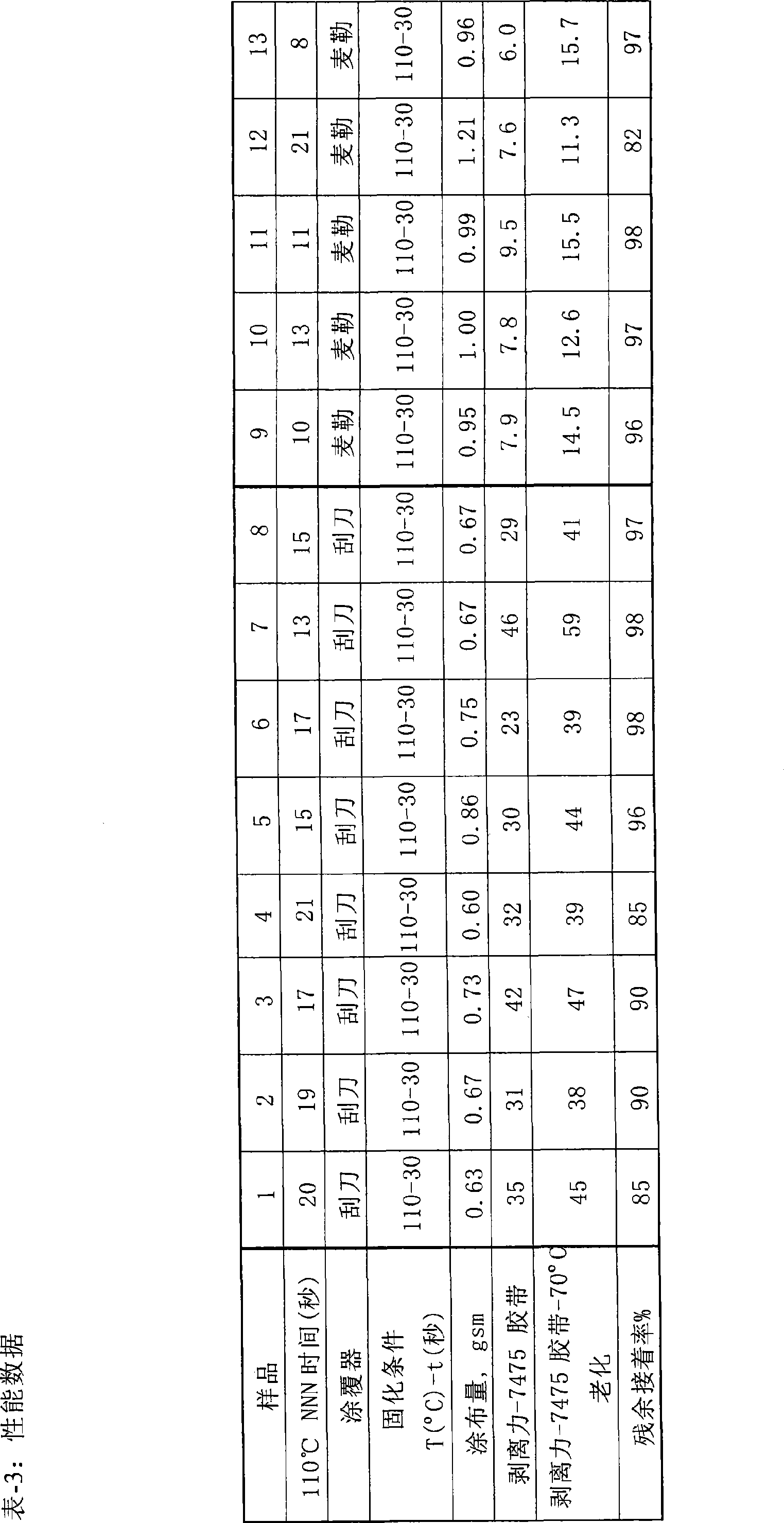

[0195] Examples and comparisons are given below to specifically describe the present invention. However, the present invention is not limited to the following examples. In the following examples and comparisons, parts are parts by weight and ppm means ppm by weight in each case. Viscosity, silicone coating curing speed, peeling force, residual adhesion ratio (SAS%), and coating weight were measured at 25° C. by the following methods.

[0196] 〔Viscosity〕

[0197] The viscosity of the organopolysiloxane and silicone release coating mixture was determined by using a Brookfield viscometer (Brookfield viscometer) (Model: LVF, with spindle #1, 2, 3, 4, and speed 6 to 60 rpm) at Measured at 25°C.

[0198] 〔Silicone coating〕

[0199] The silicone anti-stick coating mixture is coated on PE kraft paper (PE coater) by a knife coater (Euclid Lab Coater, model: #E BC12M1), i.e. a "squeegee". film) to provide the coat weights described in the table below, and then cured under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com