Modified waterborne polyurethane resin for safety gloves, as well as preparation method thereof

A technology of water-based polyurethane and labor protection gloves, applied in the chemical field, can solve the problems of poor wear resistance, anti-adhesion and bonding strength, achieve storage stability and good hydrolysis resistance, improve wear resistance and weather resistance, Feel good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

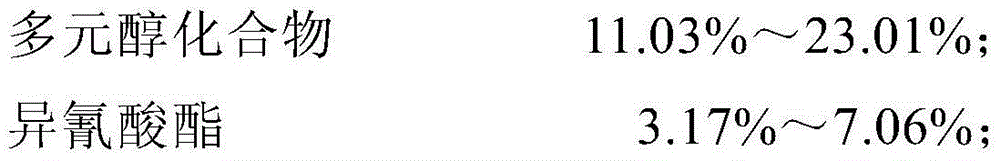

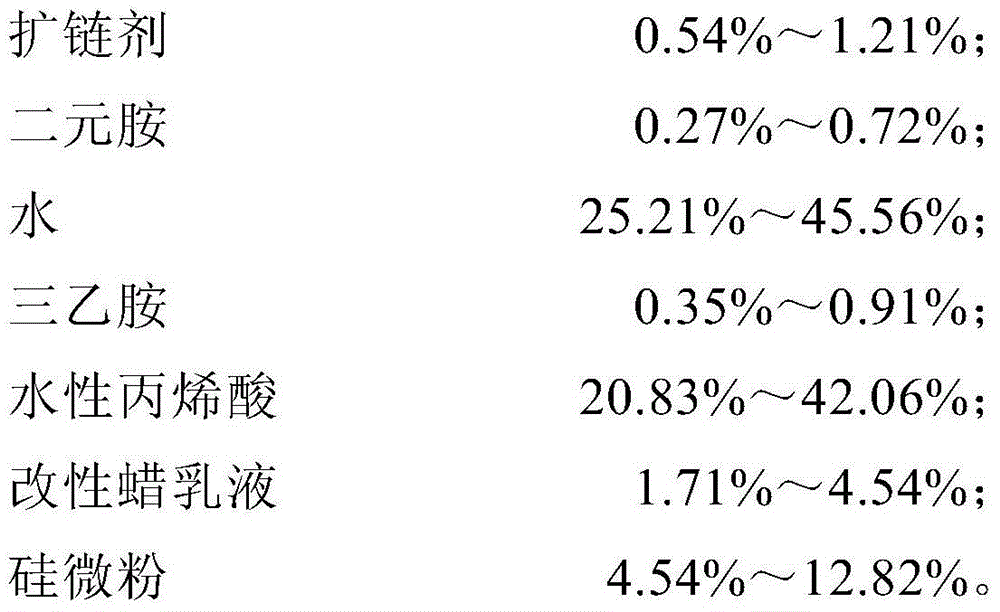

Method used

Image

Examples

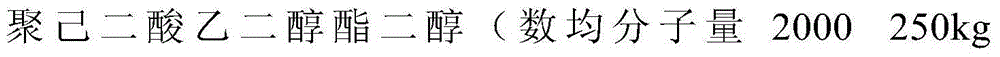

Embodiment 1

[0030]

[0031]

[0032] Put 250kg of polybutylene adipate diol and 74.35kg of isophorone diisocyanate into the reaction kettle, raise the temperature to 80-85°C, and react for 2-3 hours to reach the theoretical isocyanate content, then cool down the reaction system to Add 12.64kg of 2,2-dimethylolpropionic acid at 70~80℃, react until the theoretical isocyanate content is 2.87%, cool down the reaction system below 50℃, add 7.87kg of triethylamine for neutralization, and cool down to below 40℃ A polyurethane prepolymer is obtained. Put 527.66kg of deionized water into the emulsification tank, add 344.86kg of the synthesized prepolymer at a dispersion speed of 1000~1200r / min, add 6.92kg of anhydrous ethylenediamine and the residual isocyanate in the system after emulsification for 40~60min Cyanate reacted, and obtained water-based polyurethane emulsion after reacting for 30 minutes.

[0033] Then add 293.14kg of water-based acrylic acid, 58.63kg of ultra-fine spherical si...

Embodiment 2

[0035]

[0036]

[0037] Put 200kg of polybutylene adipate diol and 64.86kg of isophorone diisocyanate into the reaction kettle, raise the temperature to 80-85°C, react for 2-3 hours to reach the theoretical isocyanate content, then cool down the reaction system Add 11.03kg of 2,2-dimethylolpropionic acid to 70-80°C, react until the theoretical isocyanate content is 3.33%, cool the reaction system below 50°C, add 7.08kg of triethylamine for neutralization, and cool down to 40°C The polyurethane prepolymer was obtained as follows. Put 592.27kg of deionized water into the emulsification tank, add 282.97kg of the synthesized prepolymer at a dispersion speed of 1000~1200r / min, add 6.58kg of anhydrous ethylenediamine and the residual isocyanate in the system after emulsification for 40~60min Cyanate reacted, and obtained water-based polyurethane emulsion after reacting for 30 minutes.

[0038] Then add 592.27kg of water-based acrylic acid, 197.42kg of ultra-fine spherical si...

Embodiment 3

[0040]

[0041] Put 200kg of polybutylene adipate diol and 54.43kg of isophorone diisocyanate into the reaction kettle, raise the temperature to 80-85°C, and react for 2-3 hours to reach the theoretical isocyanate content, then cool the reaction system to Add 9.23kg of 2,2-dimethylolpropionic acid at 70~80℃, the reaction reaches a theoretical isocyanate content of 2.42%, the temperature of the reaction system is lowered to below 50℃, neutralized by adding 5.92kg of triethylamine, and the temperature is lowered to below 40℃ A polyurethane prepolymer is obtained. Put 509.14kg of deionized water into the emulsification tank, add 269.58kg of the synthesized prepolymer at a dispersion speed of 1000~1200r / min, add 4.57kg of anhydrous ethylenediamine and the residual isocyanate in the system after emulsification for 40~60min Cyanate reacted, and obtained water-based polyurethane emulsion after reacting for 30 minutes.

[0042] Then add 261.10kg of water-based acrylic acid, 52.22k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com