Ceramic coating and application thereof as well as non-stick tableware and preparation method thereof

A technology for ceramic coatings and tableware, applied in the field of non-stick tableware and the preparation of the non-stick tableware, and the field of ceramic coatings, can solve the problems of difficulty in meeting spiritual and cultural aesthetic needs, single appearance and color expression, and weak non-stick layer, and achieve rich The effect of spiritual and cultural aesthetic needs, high degree of integration, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: This embodiment 1 provides four kinds of ceramic coatings with different component ratios

[0017] The concrete composition weight portion proportioning of four kinds of ceramic coatings is respectively as follows:

[0018] The first one: 4 parts of methyltrimethoxysilane, 35 parts of silica sol, 17 parts of isopropanol, and 13 parts of distilled water.

[0019] The second type: 4 parts of methyltrimethoxysilane, 35 parts of silica sol, 17 parts of isopropanol, 13 parts of distilled water, and 18 parts of yellow toner.

[0020] The third type: 5 parts of methyltrimethoxysilane, 37 parts of silica sol, 20 parts of isopropanol, 15 parts of distilled water, and 20 parts of cyan toner.

[0021] The fourth type: 6 parts of methyltrimethoxysilane, 40 parts of silica sol, 22 parts of isopropanol, 18 parts of distilled water, and 22 parts of red toner.

[0022] Weigh the corresponding component weights of the four kinds of ceramic coatings as required, and then ...

Embodiment 2

[0023] Embodiment 2: This embodiment 2 provides a kind of non-stick tableware and its preparation method

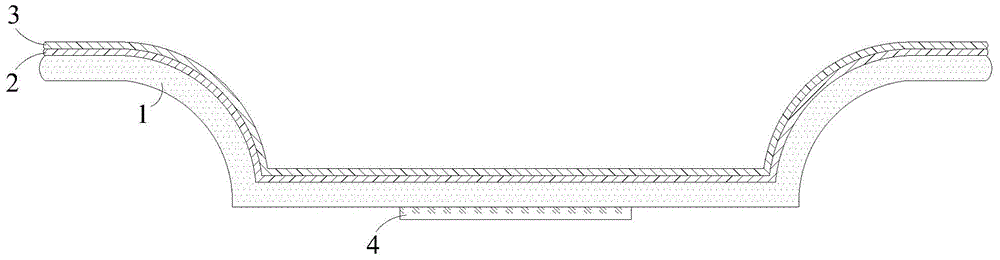

[0024] Such as figure 1 As shown, the non-stick tableware of the present embodiment includes a glass substrate 1, the upper surface of the glass substrate 1 is sprayed with a layer of color-ceramic coating 2, and the upper surface of the color-one ceramic coating 2 is sprayed with a layer of color-two ceramic coating 3. The lower surface of the glass substrate 1 is also pasted with decals 4 . Color one ceramic coating 2 is formed by spraying the third kind of ceramic coating in embodiment 1, and color two ceramic coating 3 is formed by spraying the fourth kind of ceramic coating in embodiment 1.

[0025] The preparation method of the non-stick tableware in the present embodiment 2 comprises the following steps:

[0026] (1) Pretreatment: Use brown emery with a particle size of 140-180 μm to dry-spray the surface of the glass substrate;

[0027] (2) Preheating: the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com