Environment-friendly multifunctional composite negative-pressure drain wound-protection sponge and preparation method thereof

An environmentally friendly, negative pressure drainage technology, applied in the field of medical negative pressure sponges, can solve the problems of wound granulation tissue growing into the cavity, secondary wound damage, easy drying and hardening, etc., to improve safety and biocompatibility Sexuality, preventing tissue adhesion, and reducing artificial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

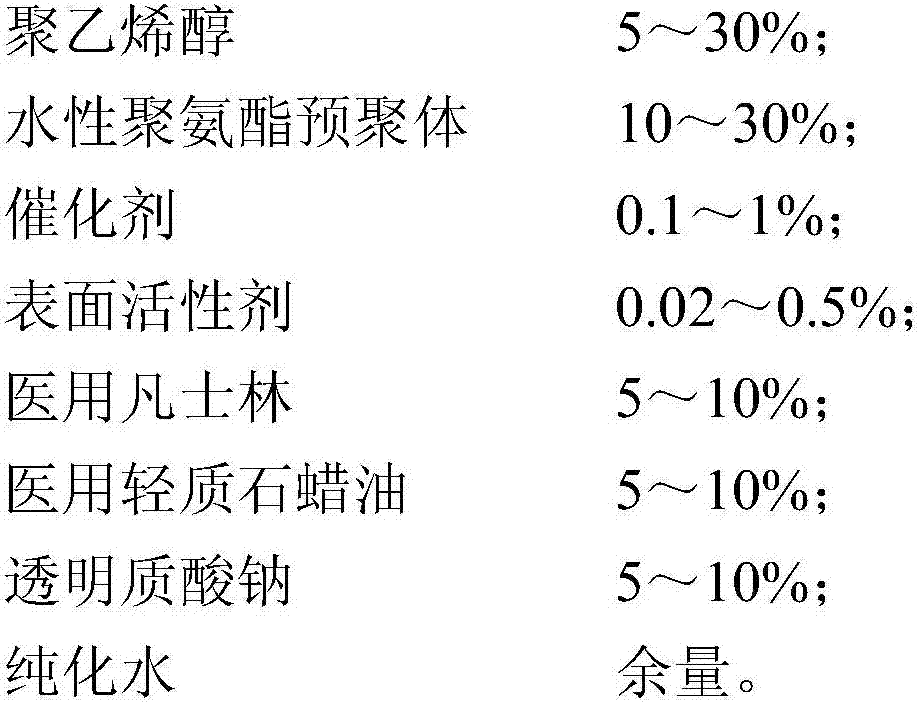

[0028] The raw materials of an environment-friendly multifunctional composite negative pressure drainage and wound protection sponge are prepared respectively according to the following ratios:

[0029]

[0030] Among them, the polymerization degree of polyvinyl alcohol is 80,000; the catalyst is stannous octoate; the surfactant is sodium lauryl sulfate; the water-based polyurethane prepolymer is polyester type.

[0031] Prepare an environment-friendly multifunctional composite negative pressure drainage wound protection sponge according to the following steps:

[0032] Step A: Dissolve PVA in purified water at 90-100°C and stir for 60-90 minutes to a colorless and transparent solution, then cool down to 50-60°C to obtain system a with a content of

[0033] Step B: Take 70% of system a, add water-based polyurethane prepolymer, surfactant and catalyst and stir rapidly for 1-10 minutes to obtain system b;

[0034] Step C: take medical vaseline and light paraffin oil for medi...

Embodiment 2

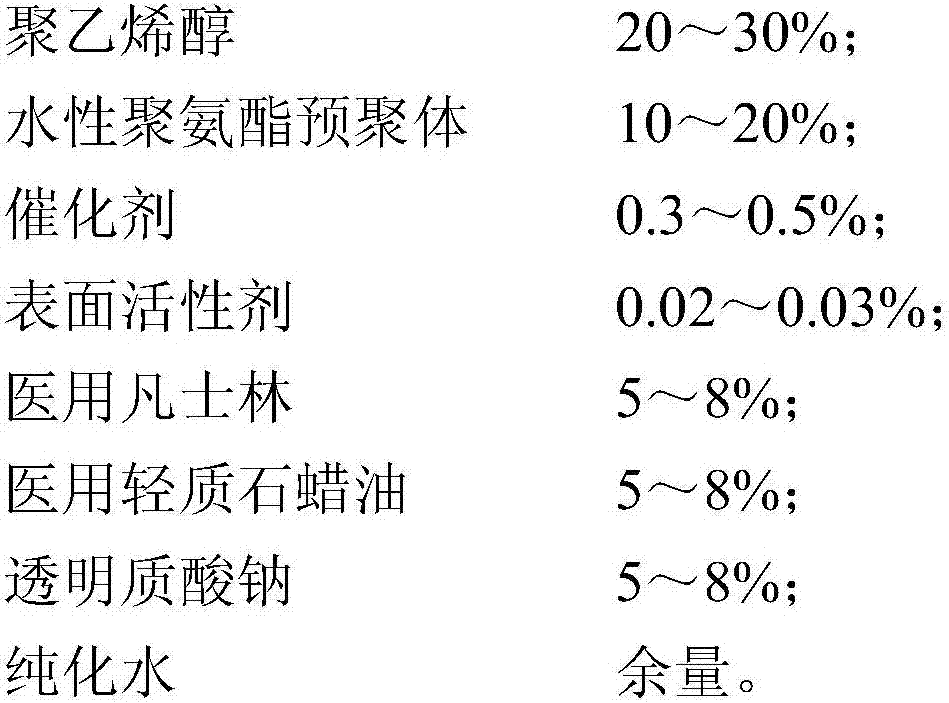

[0039] The raw materials of an environment-friendly multifunctional composite negative pressure drainage and wound protection sponge are prepared respectively according to the following ratios:

[0040]

[0041]

[0042] Wherein, the degree of polymerization of polyvinyl alcohol is 100,000; the catalyst is triethanolamine; the surfactant is sodium lauryl sulfate; the water-based polyurethane prepolymer is polyether type.

[0043] Prepare an environment-friendly multifunctional composite negative pressure drainage wound protection sponge according to the following steps:

[0044] Step A: Dissolve PVA in purified water at 90-100°C and stir for 60-90 minutes to a colorless and transparent solution, then cool down to 50-60°C to obtain system a with a content of

[0045] Step B: Take 65% of system a, add water-based polyurethane prepolymer, surfactant and catalyst and stir rapidly for 1-10 minutes to obtain system b;

[0046] Step C: take medical vaseline and light paraffin ...

Embodiment 3

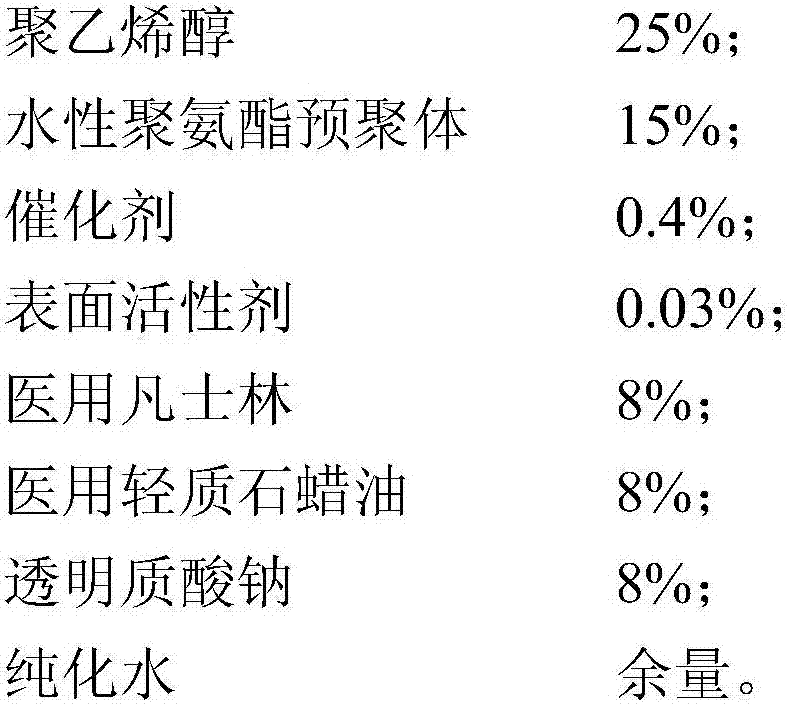

[0051]The raw materials of an environment-friendly multifunctional composite negative pressure drainage and wound protection sponge are prepared respectively according to the following ratios:

[0052]

[0053]

[0054] Among them, the polymerization degree of polyvinyl alcohol is 120,000; the catalyst is pentamethyldiethylenetriamine; the surfactant is stearic acid; the water-based polyurethane prepolymer is polyolefin type.

[0055] Prepare an environment-friendly multifunctional composite negative pressure drainage wound protection sponge according to the following steps:

[0056] Step A: Dissolve PVA in purified water at 90-100°C and stir for 60-90 minutes to a colorless and transparent solution, then cool down to 50-60°C to obtain system a with a content of

[0057] Step B: Take 60% of system a, add water-based polyurethane prepolymer, surfactant and catalyst and stir rapidly for 1-10 minutes to obtain system b;

[0058] Step C: take medical vaseline and light para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com