Solid wood fiber/SiO2 aerogel composite thermal insulation material and preparation method thereof

A technology of composite thermal insulation material and airgel, which is applied in the field of thermal insulation materials, can solve the problems of low mechanical strength and poor toughness of silica airgel, and solve the problems of easy water absorption and low utilization rate, increased hydrophobicity, and improved thermal insulation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

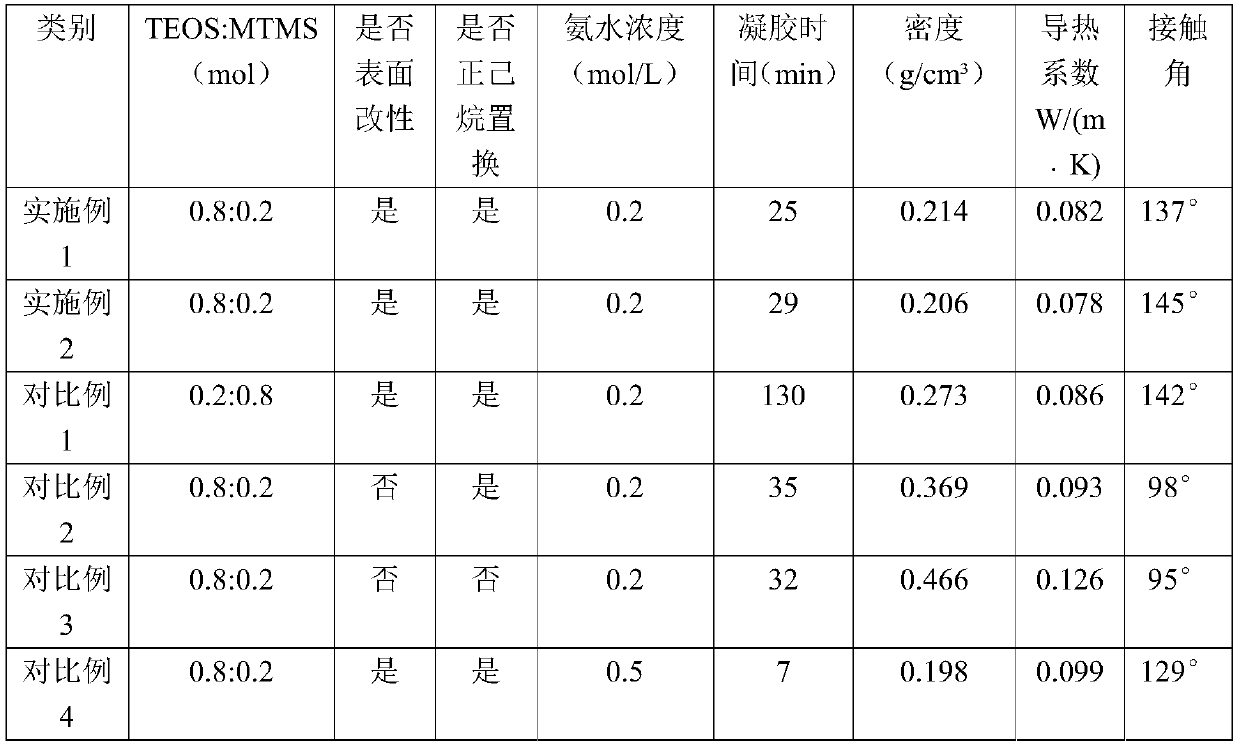

Examples

Embodiment 1

[0028] The solid wood fiber / SiO 2 The preparation method of the airgel composite thermal insulation material specifically comprises the following steps:

[0029] (1) Preparation of wood fiber matrix: 40g sodium hydroxide and 20.16g sodium sulfite were dissolved in 400ml water and mixed evenly to obtain NaOH (2.5mol / L) and NaOH 2 SO 3 (0.4mol / L) of the mixed solution A, the Balse wood block (20 × 20 × 20mm) was immersed in the mixed solution A and boiled for 16h, then it was taken out and rinsed with distilled water, and placed in 2.5mol / L H 2 o 2 Boil in medium until the yellow color disappears, take out and rinse with distilled water to obtain the balse fibrous matrix;

[0030] (2) Tetraethyl orthosilicate (TEOS), methyltrimethoxysilane (MTMS), absolute ethanol, deionized water, dimethylformamide (DMF) according to the ratio of 0.8:0.2:6:4:0.4 After the molar ratio is mixed uniformly, a colorless and transparent solution B is obtained, and then the balse fibrous matrix ob...

Embodiment 2

[0039] The solid wood fiber / SiO 2 The preparation method of the airgel composite thermal insulation material specifically comprises the following steps:

[0040] (1) Preparation of wood fiber matrix: 40g sodium hydroxide and 20.16g sodium sulfite were dissolved in 400ml water and mixed evenly to obtain NaOH (2.5mol / L) and NaOH 2 SO 3 (0.4mol / L) of the mixed solution A, the balse wood block (20 × 20 × 20mm) immersed in the mixed solution A boiled for 24h, took out and rinsed with distilled water, put it in H 2 0 2 (2.5mol / L) until the yellow disappears, take out and rinse with distilled water to obtain the Balse fibrous matrix;

[0041] (2) Tetraethyl orthosilicate (TEOS), methyltrimethoxysilane (MTMS), absolute ethanol, deionized water, dimethylformamide (DMF) according to the ratio of 0.8:0.2:6:4:0.4 After the molar ratio is mixed uniformly, a colorless and transparent solution B is obtained, and then the balse fibrous matrix obtained in the step (1) is fully immersed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com