Fire prevention and extinguishing gel material for mine and preparation method thereof

A gel material, fire prevention technology, applied in fire rescue and other directions, can solve the problems of too fast, endanger the health of underground workers, waste of raw materials, etc., and achieve the effects of simple preparation process, controllable gel time, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

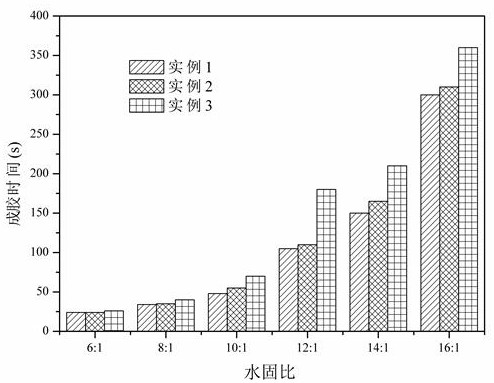

Embodiment 1

[0024] Take 0.6g of solid water glass, 0.3g of sodium bicarbonate, 0.8g of fly ash, 0.7g of calcium hydroxide, 0.5g of magnesium aluminum silicate and 2.5g of sodium bentonite and mix evenly, divide the material into 6 parts according to the water-solid ratio Add water to 6:1, 8:1, 10:1, 12:1, 14:1 and 16:1 respectively and stir well to prepare fire extinguishing gel.

Embodiment 2

[0026] Take 0.65g of solid water glass, 0.35g of sodium bicarbonate, 0.75g of fly ash, 0.6g of calcium hydroxide, 0.4g of magnesium aluminum silicate and 3g of sodium bentonite and mix evenly, and divide the material into 6 parts according to the water-solid ratio of 6 : 1, 8: 1, 10: 1, 12: 1, 14: 1 and 16: 1 respectively add water and stir well to prepare fire extinguishing gel.

Embodiment 3

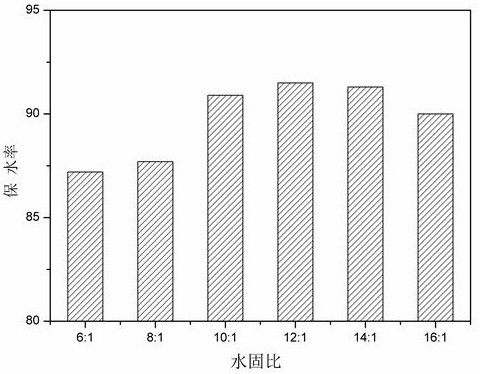

[0028] Take 0.7g solid water glass, 0.4g sodium bicarbonate, 0.7g fly ash, 0.5g calcium hydroxide, 0.3g magnesium aluminum silicate and 2g sodium bentonite and mix evenly, divide the material into 6 parts according to the water-solid ratio 6 : 1, 8: 1, 10: 1, 12: 1, 14: 1 and 16: 1 respectively add water and stir well to prepare fire extinguishing gel. For the gel-forming characteristics and colloid performance of 18 parts of fire-preventing gels prepared in Examples 1-3, the following methods were designed to test:

[0029] (1) Observing the flow of the mixture, it is measured that by changing the water-solid ratio, the gelling time of the gel can be controlled between 24 seconds and 360 seconds, which meets the "wide ratio" of short-distance filling and long-distance transport plugging need.

[0030] (2) The prepared gel is placed at room temperature, and the mass change of the gel is measured every other week and whether the surface of the gel is cracked. The experimental ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com