High performance low environmental impact detackifier

A technology of flocculant and amphoteric salt, which is applied in the field of improved separation, can solve problems such as continuous difficulties and difficulties, achieve low environmental impact, improve anti-sticking performance, and improve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

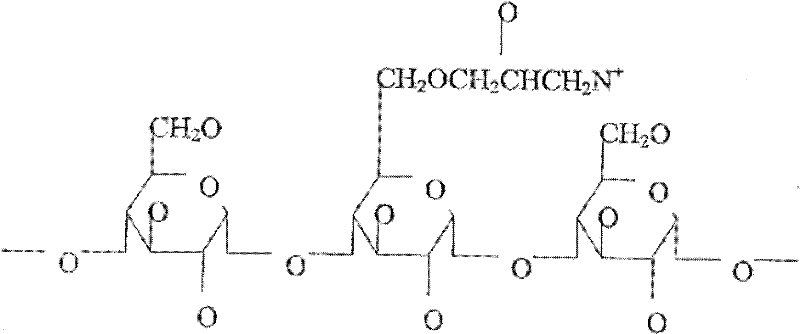

Image

Examples

Embodiment 1

[0038] This example demonstrates the effectiveness of compositions of the present invention prepared by the aforementioned treatment "A".

[0039] paint

Embodiment 2

[0041] The examples that follow demonstrate the importance of each component in the performance of the invention. In Example 2, the polymer component has been removed, leaving only cationic starch and aluminum hydrochlorate (ACH). (In this and subsequent examples used, the amount of residual chemical constituents was increased to maintain an equal amount of active solids for all tests.)

[0042] paint

Embodiment 3

[0044] In Example 3, the cationic starch component has been removed, leaving only the polymer and aluminum hydrochlorate (ACH).

[0045] paint

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com