Low-temperature curing polyether sulfone coating composition and preparation method thereof, as well as coating process

A technology of polyethersulfone and composition, which is applied in the field of low-temperature curing polyethersulfone coating composition and its preparation, which can solve the problems of polyethersulfone coatings that require high-temperature curing performance and decrease, and achieve acid, alkali, salt and organic solvent resistance Strong ability, good anti-corrosion performance, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

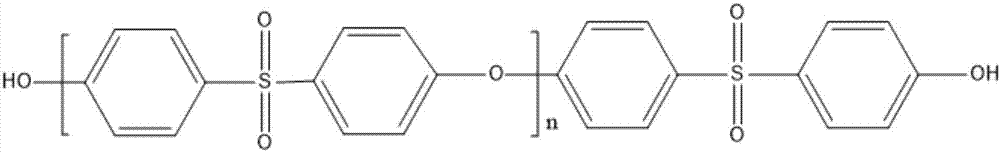

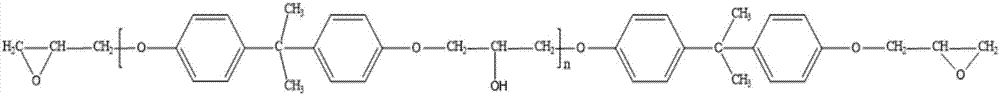

Method used

Image

Examples

Embodiment 1

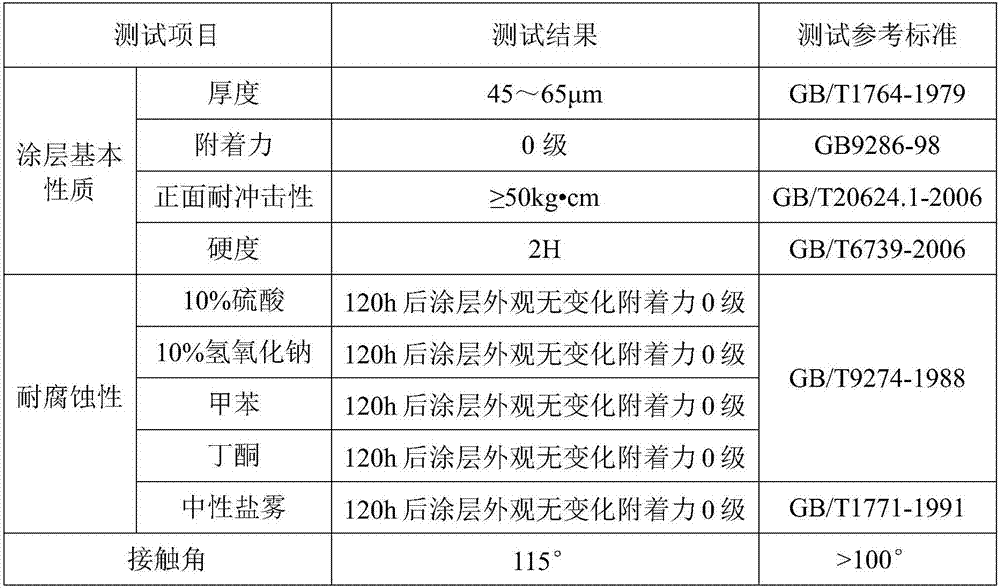

[0048]At a stirring speed of 3800r / min, 18g of polyethersulfone resin with an inherent viscosity of 0.34 was dissolved in a composite solvent composed of 36g of dimethylacetamide, 28g of toluene, and 8g of methyl ethyl ketone, and then 4g of polyethersulfone resin was added in sequence. Tetrafluoroethylene micropowder, 3.5g of chromium trioxide, 0.5g of titanium dioxide, 1.4g of organic bentonite and 3.3g of epoxy resin E44 were ground in a sand mill for 2 hours to prepare a coating. Add 2.3g modified phenalkamide curing agent LITE3100 (manufactured by U.S. Cardolite Company) before spraying, stir for 0.3 hour and ripen, utilize air spray gun and air compressor to spray the coating after ripening on the steel plate through sandblasting, at 168 °C for 2 hours, then cooled to room temperature for testing.

[0049] Test Results:

[0050]

Embodiment 2

[0052] At a stirring speed of 3600r / min, dissolve 20g of polyethersulfone resin with a logarithmic viscosity of 0.34 in a composite solvent consisting of 42g of dimethylacetamide and 30g of toluene, and then add 1g of polytetrafluoroethylene micropowder in sequence , 4g of chromium trioxide, 1g of fumed silica and 4g of epoxy resin E44 were ground in a sand mill for 4 hours to make a coating. Before spraying, add 3g of modified phenalkamide curing agent LITE3100 (manufactured by Cardolite, USA), stir for 0.4 hours to mature, and use an air spray gun and an air compressor to spray the cured coating on the steel plate through sandblasting, at 170 ° C Bake dry for 6 hours, then cool to room temperature for testing.

[0053] Test Results:

[0054]

Embodiment 3

[0056] At a stirring speed of 3400r / min, 15g of polyethersulfone resin with an inherent viscosity of 0.34 was dissolved in a composite solvent composed of 30g of dimethylacetamide, 35g of toluene, and 8g of methyl ethyl ketone, and then 5g of polyethersulfone resin was added in sequence. Tetrafluoroethylene micropowder, 2g of graphite, 4g of titanium dioxide, 2g of organic bentonite and 2.5g of epoxy resin E44 were ground in a sand mill for 6 hours to prepare a coating. Add 1.6g modified phenalkamide curing agent LITE3100 (manufactured by U.S. Cardolite company) before spraying, stir for 0.5 hour and ripen, utilize air spray gun and air compressor to spray the coating after ripening on the steel plate through blasting, at 170 °C for 2 hours, then cooled to room temperature for testing.

[0057] Test Results:

[0058]

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com