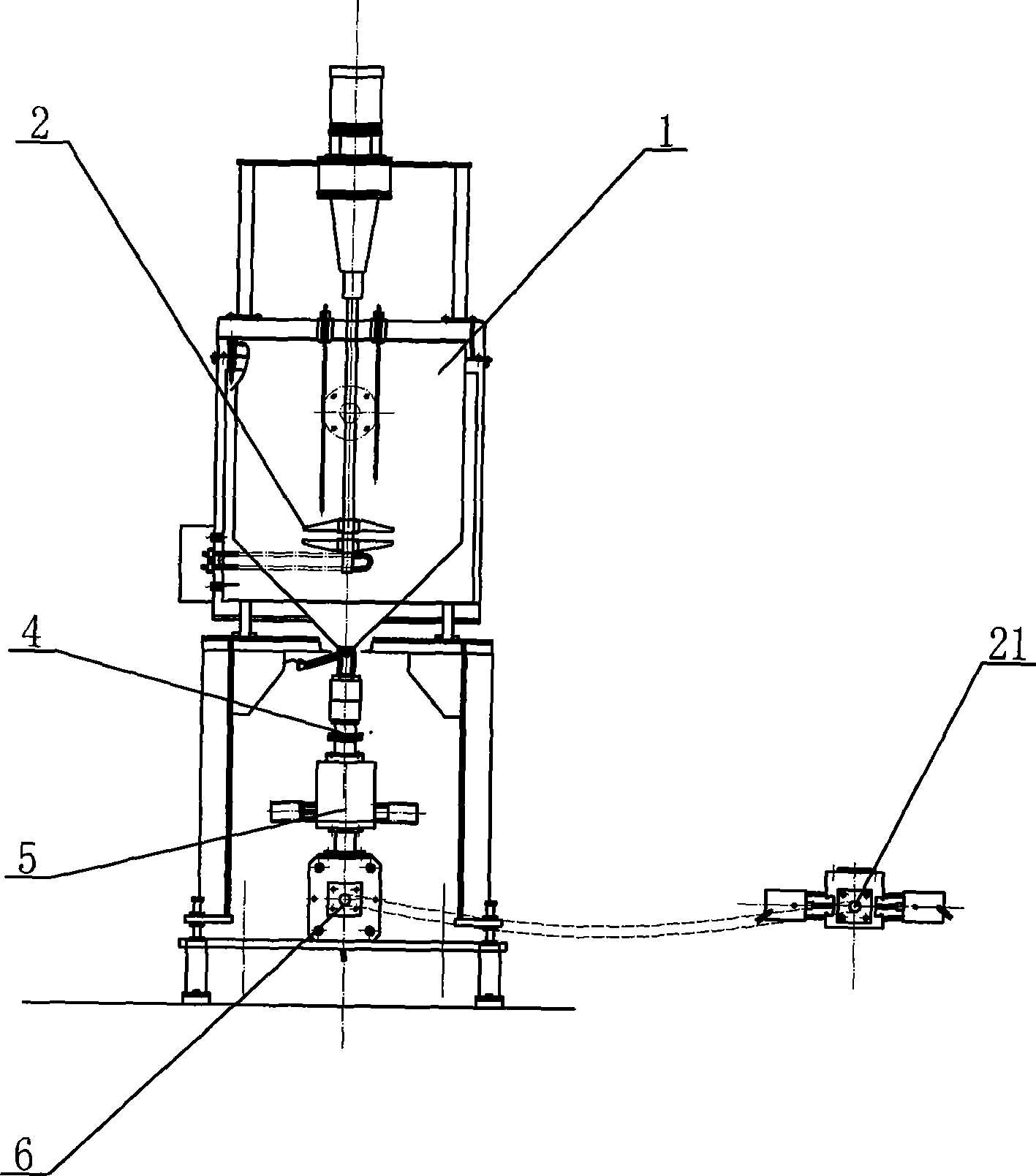

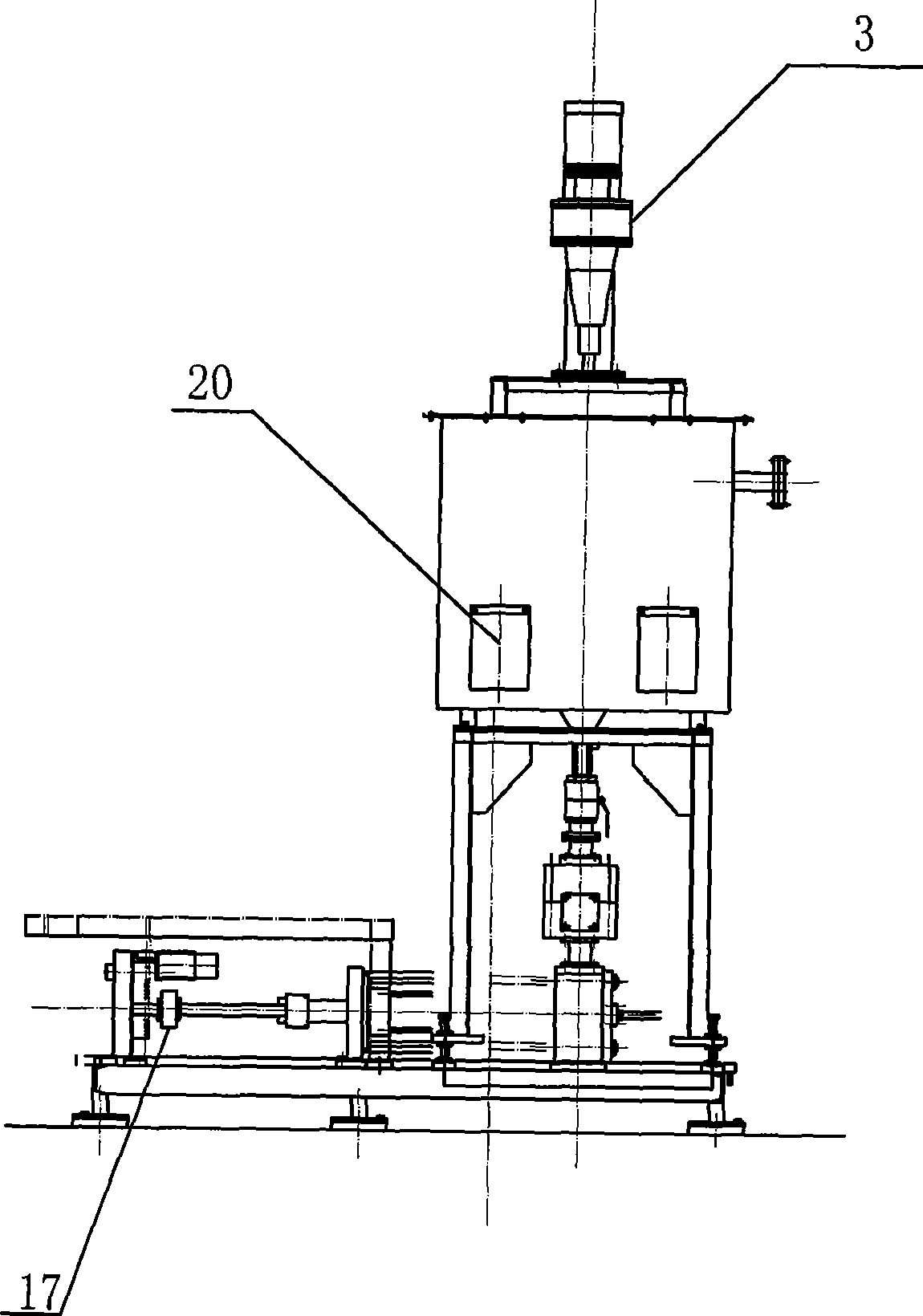

Material injecting device of magnetic material hydraulic press

A technology of magnetic materials and hydraulic presses, applied in the field of hydraulic presses, can solve the problems of low accuracy, long adjustment process, affecting product qualification rate, etc., and achieve the effect of improving product production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

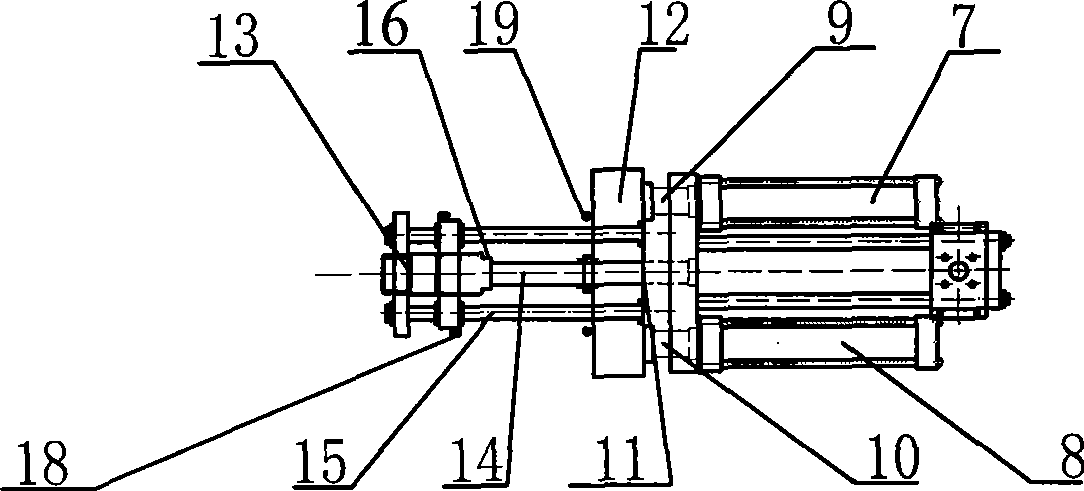

[0015] This embodiment is the automatic compensation and adjustment steps of the injection volume of the injection cylinder:

[0016] Fill Piston Stop Position:

[0017] The position of the injection piston stopper needs to be adjusted accordingly according to the mold, and it will be automatically adjusted according to the thickness of the green body during automatic continuous operation. After pressing out a normal green body, enter the current injection piston stopper in this column Position for memory. When using the same mold again, readjust the current position of the injection piston stopper according to the data memorized in this column. Setting range: 0.0-300.0 Injection waiting time:

[0018] Set the waiting time for the injection action to start after the upper and lower touch is closed.

[0019] Injection time:

[0020] Set the monitoring time of the injection action, if it exceeds this time, it will be abnormal. Green body thickness correction amount:

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com