A multi-layer vertical biological fermentation drying tower and drying method

A technology of biological fermentation and drying tower, which is applied in biological sludge treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc. It can solve the problems of uncontrollable fermentation process and achieve the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] After the dewatered sludge is mixed with 80% by weight, 10% of conditioning agent (plant residue dry powder material) and 10% of drying material (sludge material after fermentation and drying), it is sent into the mixing screw machine and stirred evenly, and the water content is Between 68%-70%, it becomes fermented material.

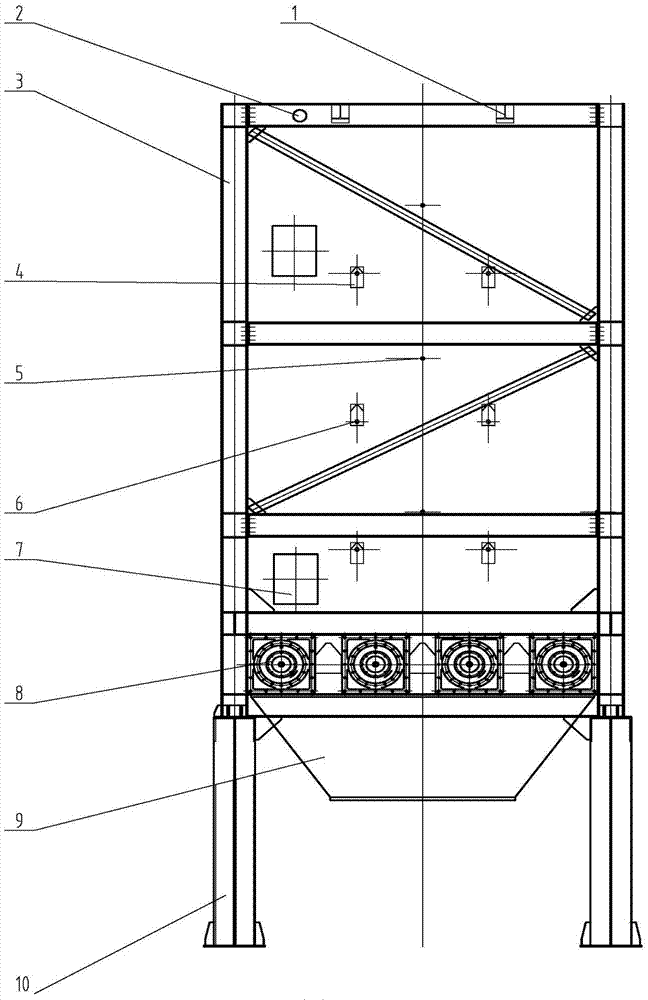

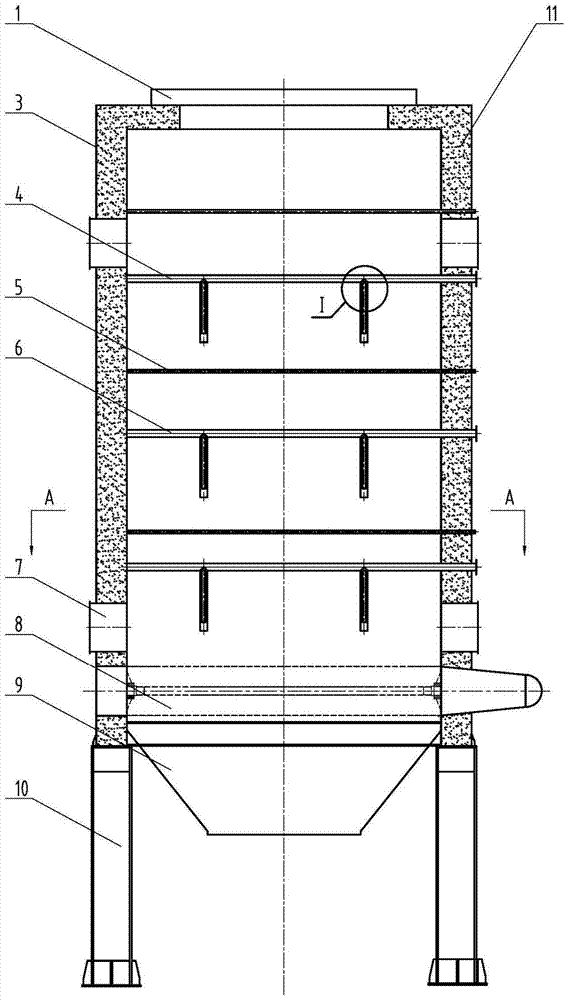

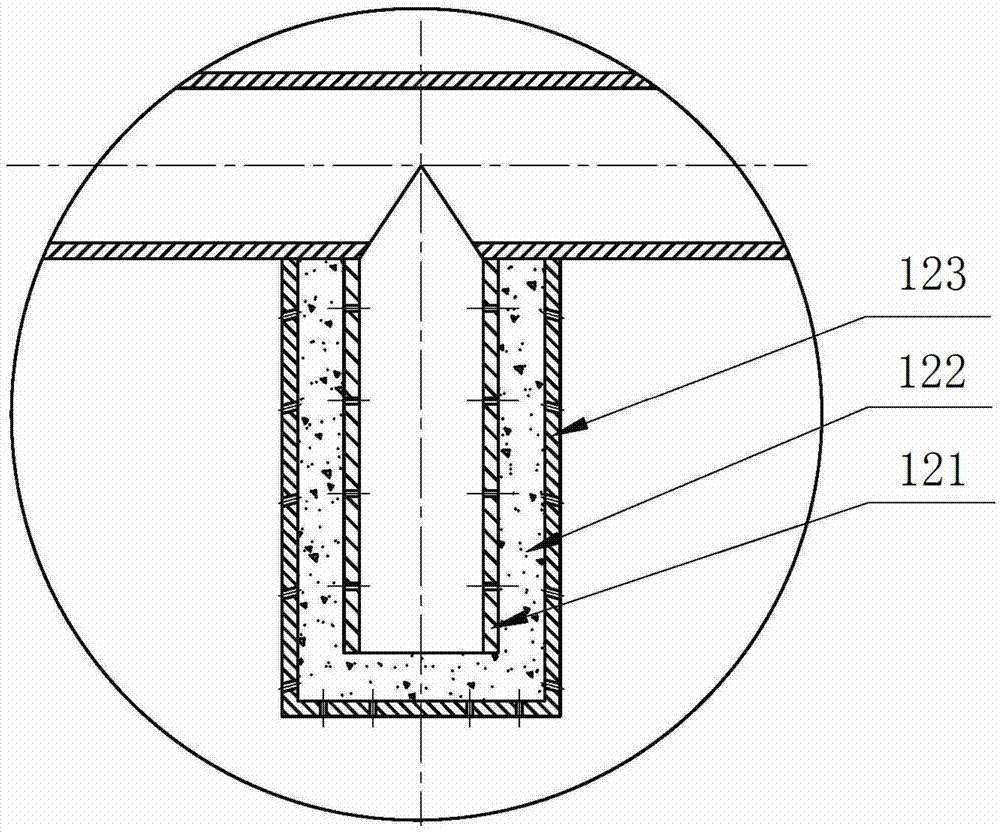

[0054] The fermentation material is sent into the drying tower divided into three layers, and then passes through the fermentation culture area of the upper layer at 45°C, the middle layer at 55°C, and the bottom layer at 45°C, and is discharged by the unloader to leave the drying tower. 55%, the whole process takes about 96h.

[0055] After the dewatered sludge is aerobically fermented in a multi-layer vertical biological fermentation drying tower, the mortality rate of roundworm eggs is >95%; Nitrogen, phosphorus and potassium should be 5% and above, and organic matter should be 35% and above.

Embodiment 2

[0057] After the dewatered sludge is mixed with 60% by weight, 10% of conditioning agent (plant residue dry powder material) and 30% of dry material (secondary fermentation sludge material), it is sent into the mixing screw machine to stir evenly, and the moisture content is Between 68%-70%, it becomes fermented material.

[0058] The fermentation material is sent into the primary drying tower divided into three layers, successively passes through the fermentation culture area of 45°C in the upper layer, 55°C in the middle layer, and 45°C in the bottom layer, and leaves the primary drying tower through unloading machine. The content is about 55%, and the whole process takes about 96 hours.

[0059] The primary fermentation material is sent into the secondary drying tower divided into four layers, and then passes through the fermentation culture area of the first layer at 45°C, the second layer at 50°C, the third layer at 55°C, and the third layer at 45°C. The machine disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com