Steel slag powder produced from industrial waste sludge and its treatment method

A treatment method and technology of industrial waste slag, which is applied in the field of environmental protection of building materials, can solve the problems of difficult grinding of steel slag powder and increased power consumption, and achieve the effects of high fluidity, low power consumption and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The processing method of the steel slag powder that utilizes industrial waste sludge to produce comprises the steps:

[0023] 1) Raw material selection and proportioning: the sludge is 80% by mass percentage, and the steel slag is 20% by mass percentage; the sludge is domestic sludge, printing and dyeing sludge, and papermaking sewage discharged from sewage treatment plants. One or more of sludge, pharmaceutical sludge, and chemical sludge, the steel slag is the waste slag and steel slag discharged from the process of steelmaking materials above 1500 degrees in the steel factory;

[0024] 2) Dehydration and drying: the sludge is directly sent to the drying kiln for drying, and the drying temperature is 300 degrees;

[0025] 3) Grinding into fine powder: the dried sludge and steel slag are mixed and ground into fine powder, the specific surface area of the fine powder is 450-550m 2 / kg to get steel slag powder.

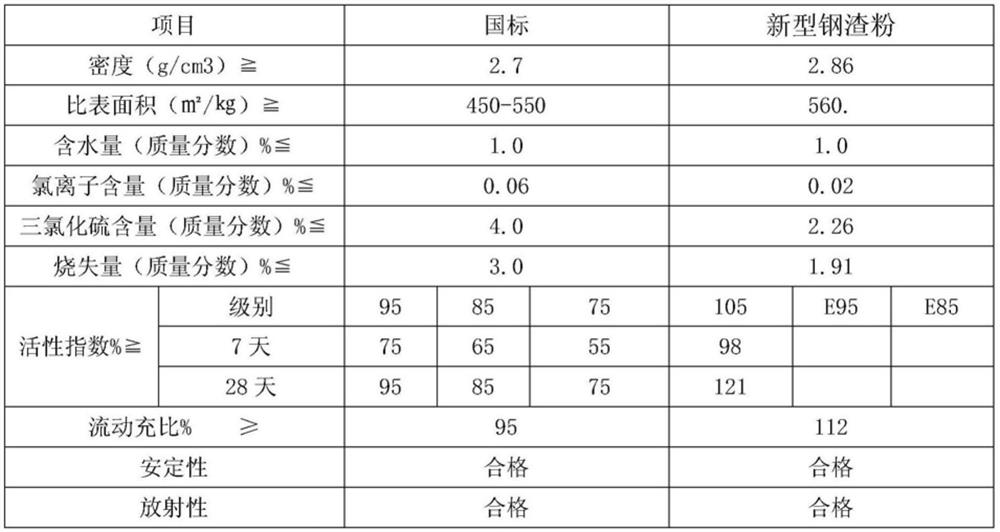

[0026] The prepared steel slag powder meets the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com