Non-contact photoelectric measurement method and device for bunker coal position

A photoelectric measurement, non-contact technology, applied in the direction of measuring devices, lubrication indicator devices, liquid/fluid solid measurement, etc., can solve the problems of emission window pollution, irregular scattering of reflected waves, inaccurate material level information, etc., to achieve measurement Good robustness, exclusion of external interference, and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

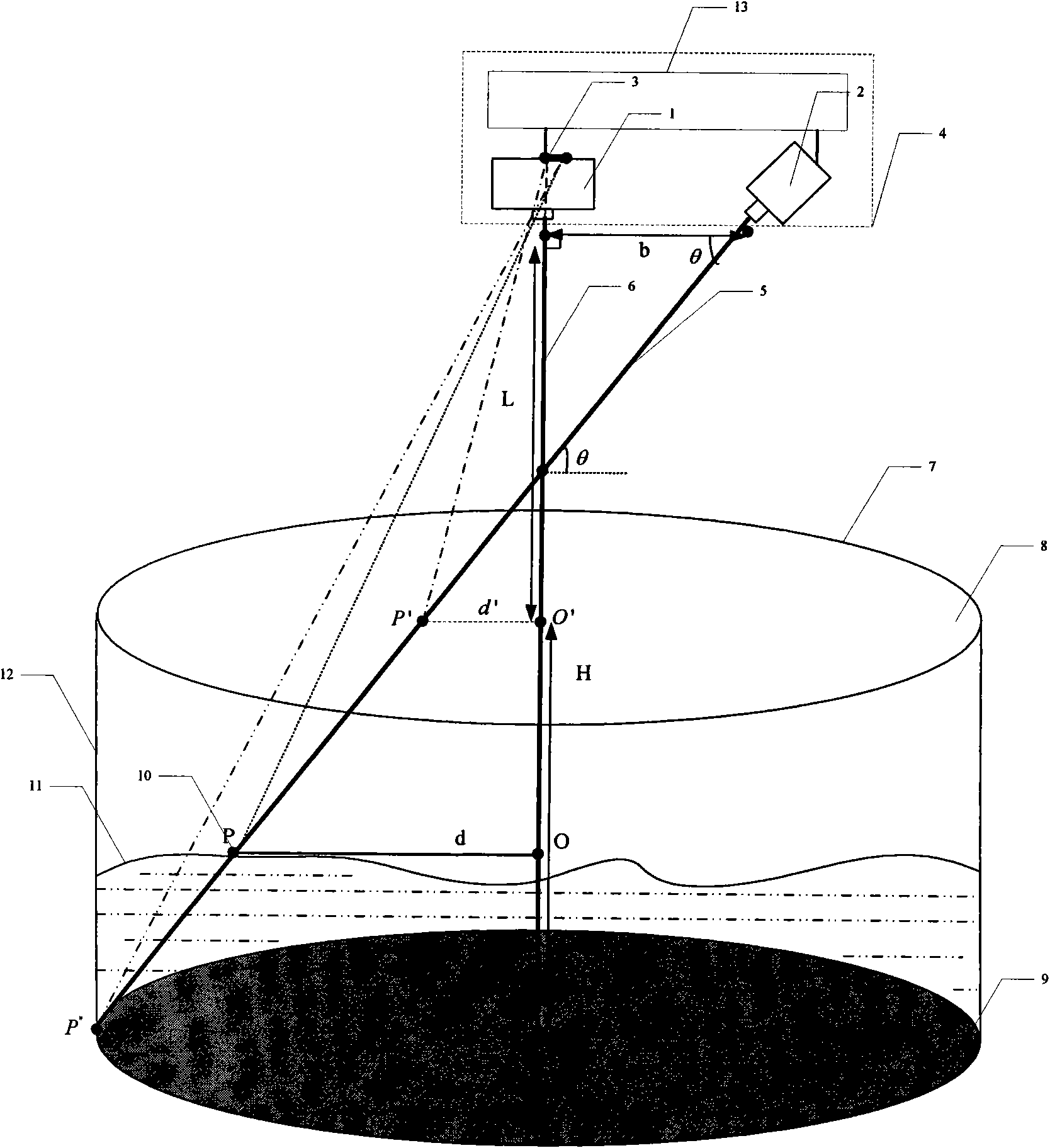

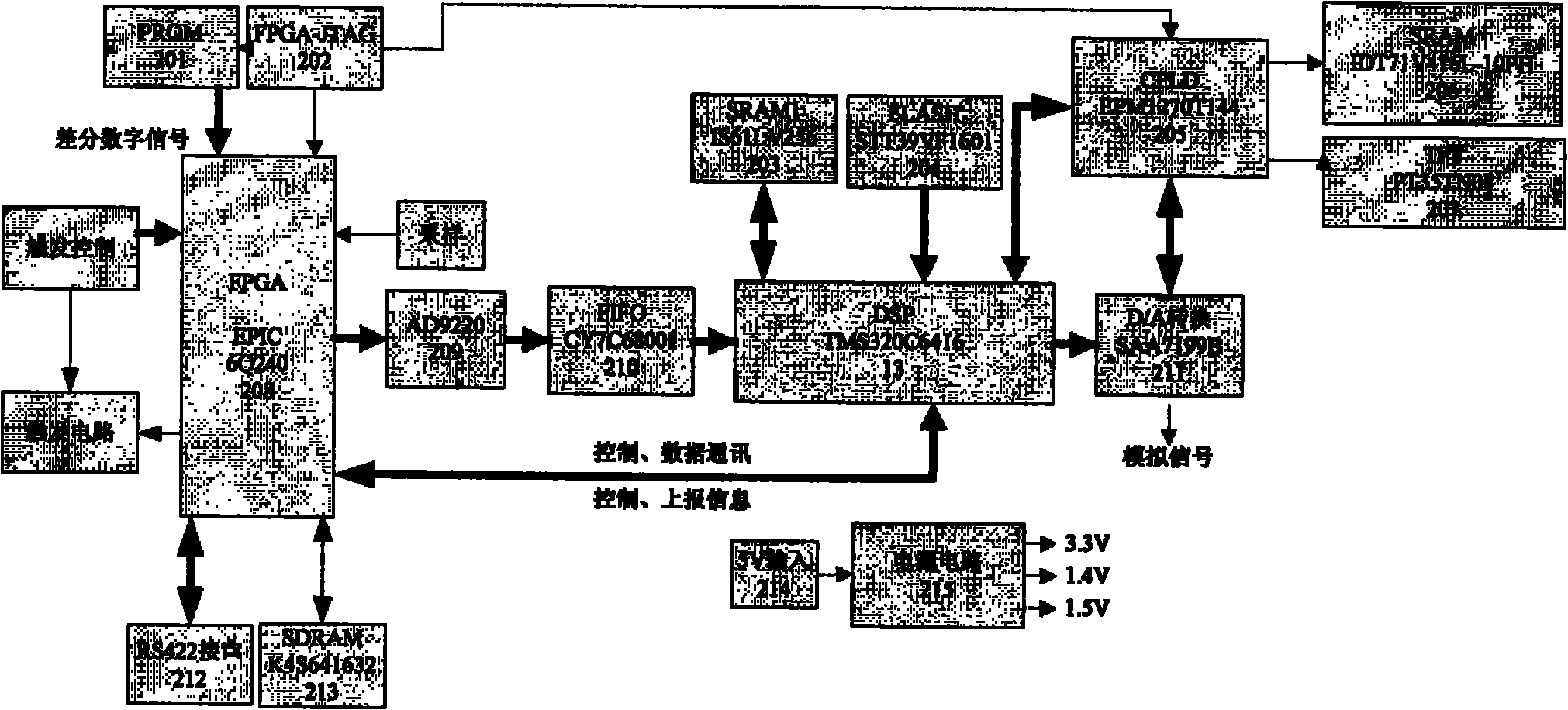

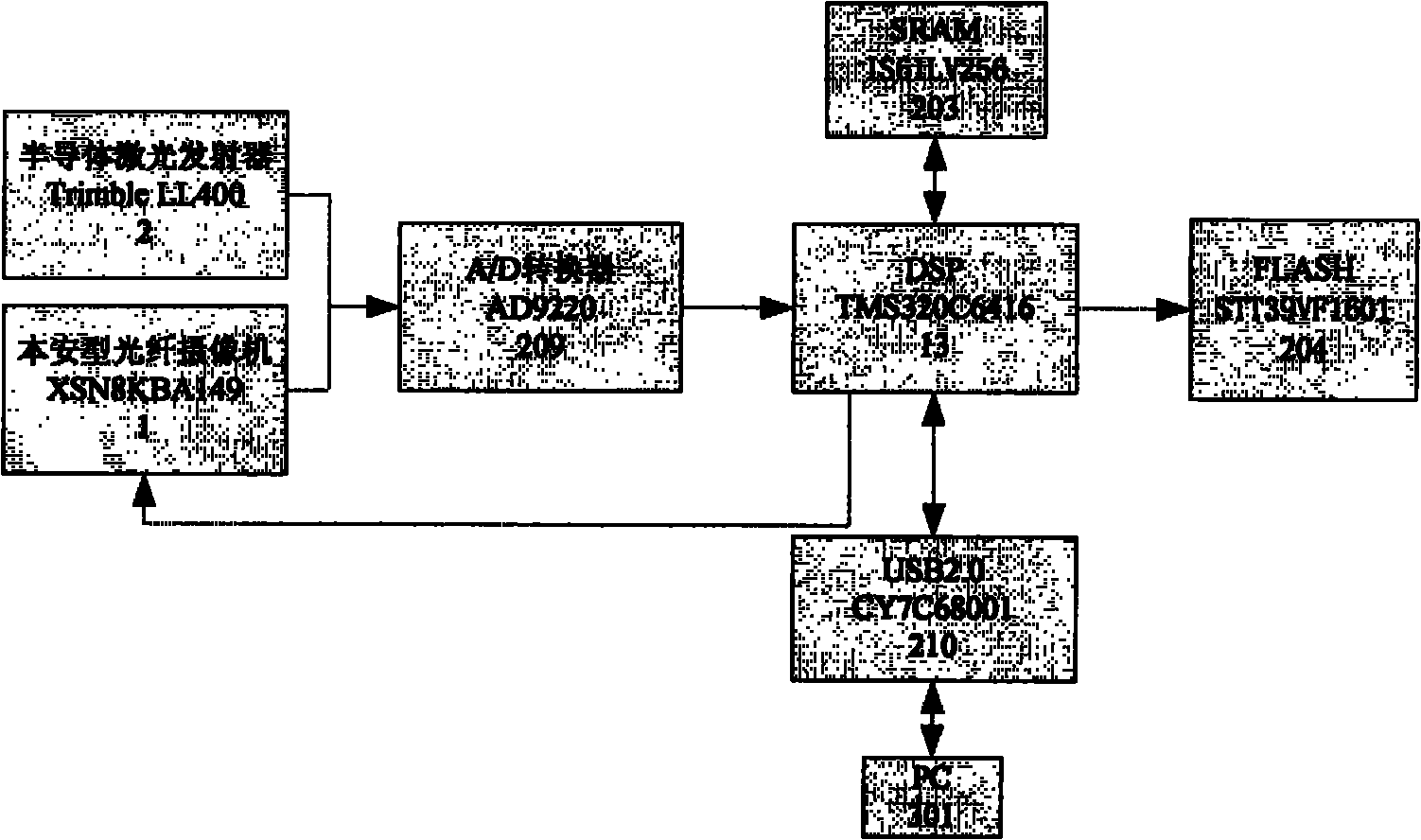

[0023] exist figure 1 Among them, the device of the present invention is fixed on the inner top of the main shaft of the cylindrical coal bunker (7), according to the prior information (baseline b, angle θ) to fix the mining intrinsically safe optical fiber camera XSN8KBA149 (1) and the long-distance semiconductor laser transmitter Trimble The location of the LL400(2). The camera optical axis (6) is perpendicular to the coal level surface (11) of the coal bunker, ensuring that the field of view of the camera (1) can cover the coal level surface (11) in the entire cylindrical coal bunker (7). The digital camera (1) adopts N gears (N=1, 2, ..., n) segmental fixed focus, and the focal length f and the aperture F of the digital camera (1) are adjusted N times, so as to meet the needs of the entire tubular coal bunker ( 7) At different coal positions (11), the digital camera (1) can capture relatively clear images. The laser transmitter (2) is installed on the top of the coal bun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com