Chemical absorption and microbial fuel cell combined synchronous flue gas desulfurization and denitration technology

A fuel cell and chemical absorption technology, which is applied in the fields of nitrous oxide capture, chemical instruments and methods, sulfur preparation/purification, etc. It can solve the problems of large investment in combined process equipment, difficulty in the application of secondary pollution, and high operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

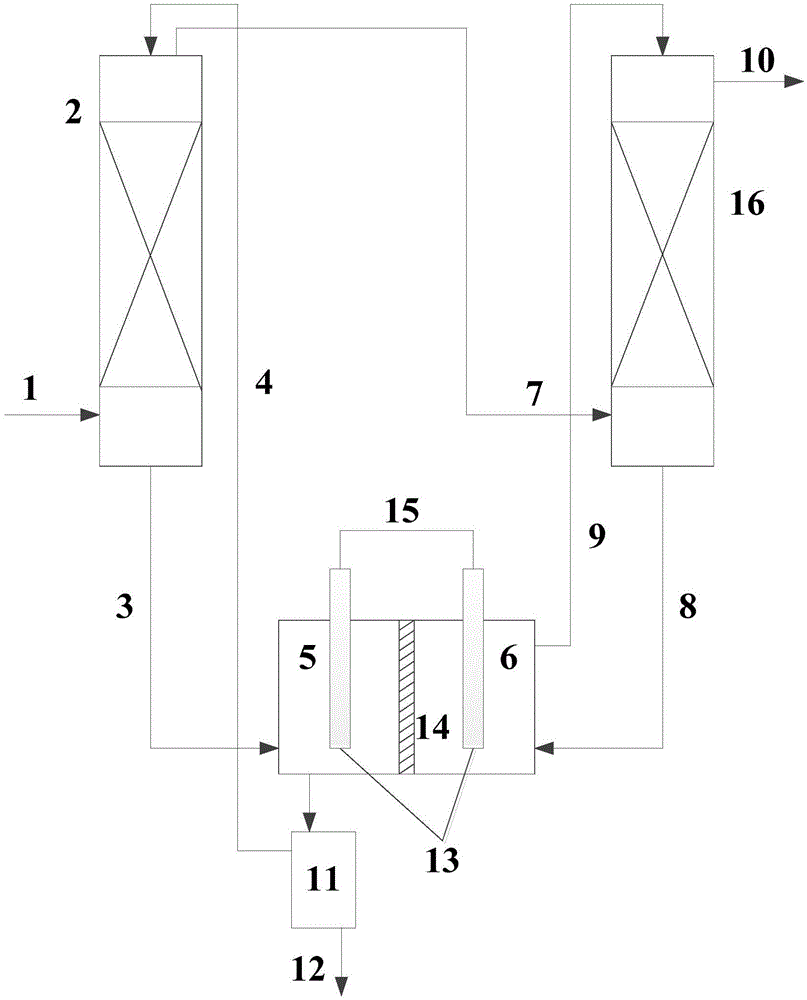

Image

Examples

Embodiment 1

[0029] A 20t / h coal-fired hot water boiler with a flue gas flow rate of 50,000m 3 / h,SO 2 The content is 1000mg / Nm 3 , NO content is 500mg / Nm 3 , the flue gas temperature is 130°C, according to the process of the present invention, when leaving the desulfurization and denitrification absorption tower, SO 2 The content is 50mg / Nm 3 , NO content is 100mg / Nm 3 ; The desulfurization efficiency is 95%, the denitrification efficiency is 80%, the elemental sulfur recovery rate is 90%, and the recovered elemental sulfur is 324kg / d.

[0030] SO 2 The absorption tower is a spray tower with a diameter of 2m, a height of 12m, and a liquid-gas ratio of 2L / Nm 3 , The desulfurization absorption liquid in the absorption process is composed of NaOH and the alkaline solution of the sulfur recovery system.

[0031] The NO absorption tower is a packed tower with a diameter of 5m, a height of 22m, and a liquid-gas ratio of 10L / Nm 3 In the absorption process, the denitrification absorption ...

Embodiment 2

[0035] A 40t / h coal-fired hot water boiler with a flue gas flow rate of 95,000m 3 / h,SO 2 The content is 1000mg / Nm 3 , NO content is 500mg / Nm 3 , the flue gas temperature is 130°C, according to the process of the present invention, when leaving the desulfurization and denitrification absorption tower, SO 2 The content is 50mg / Nm 3 , NO content is 100mg / Nm 3 ; The desulfurization efficiency is 95%, the denitrification efficiency is 80%, the elemental sulfur recovery rate is 90%, and the recovered elemental sulfur is 615.6kg / d.

[0036] SO 2 The absorption tower is a spray tower with a diameter of 3m, a height of 14m, and a liquid-gas ratio of 2L / Nm 3 , The desulfurization absorption liquid in the absorption process is composed of NaOH and the alkaline solution of the sulfur recovery system.

[0037] The NO absorption tower is a packed tower with a diameter of 7m, a height of 23m, and a liquid-gas ratio of 10L / Nm 3 In the absorption process, the denitrification absorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com