Casting carrying and separating equipment

A technology of castings and equipment, which is applied in the field of casting loading and distributing equipment, can solve problems such as unreasonable casting material distributing, and achieve the effect of saving manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

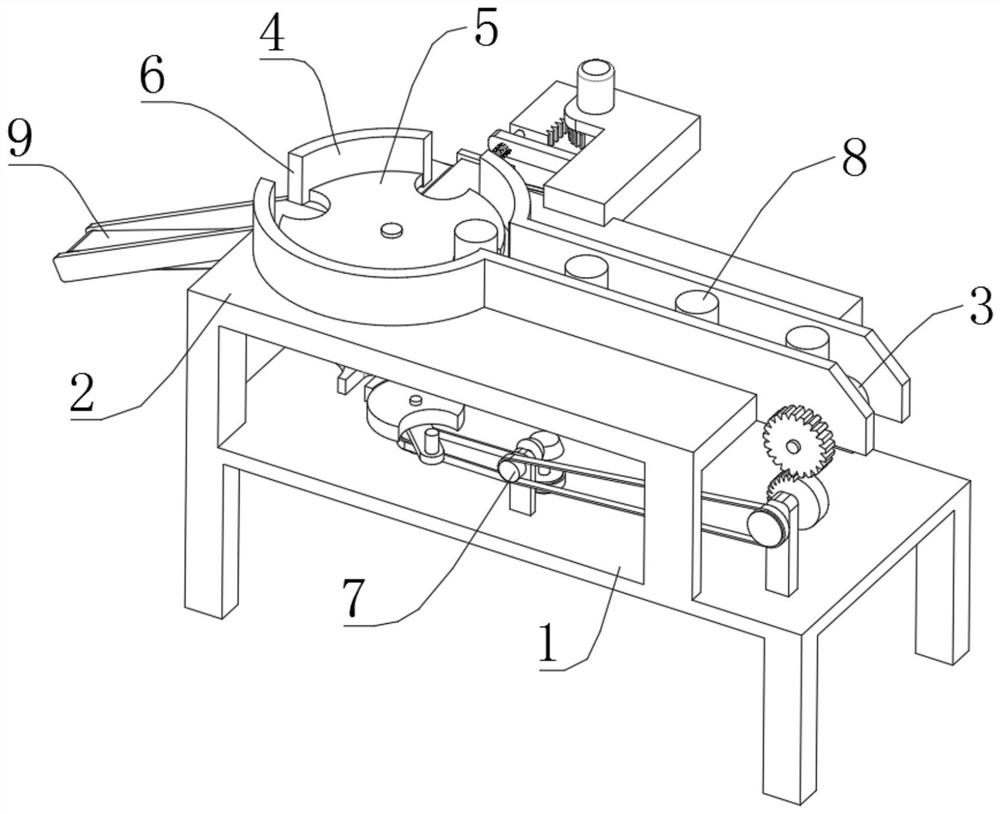

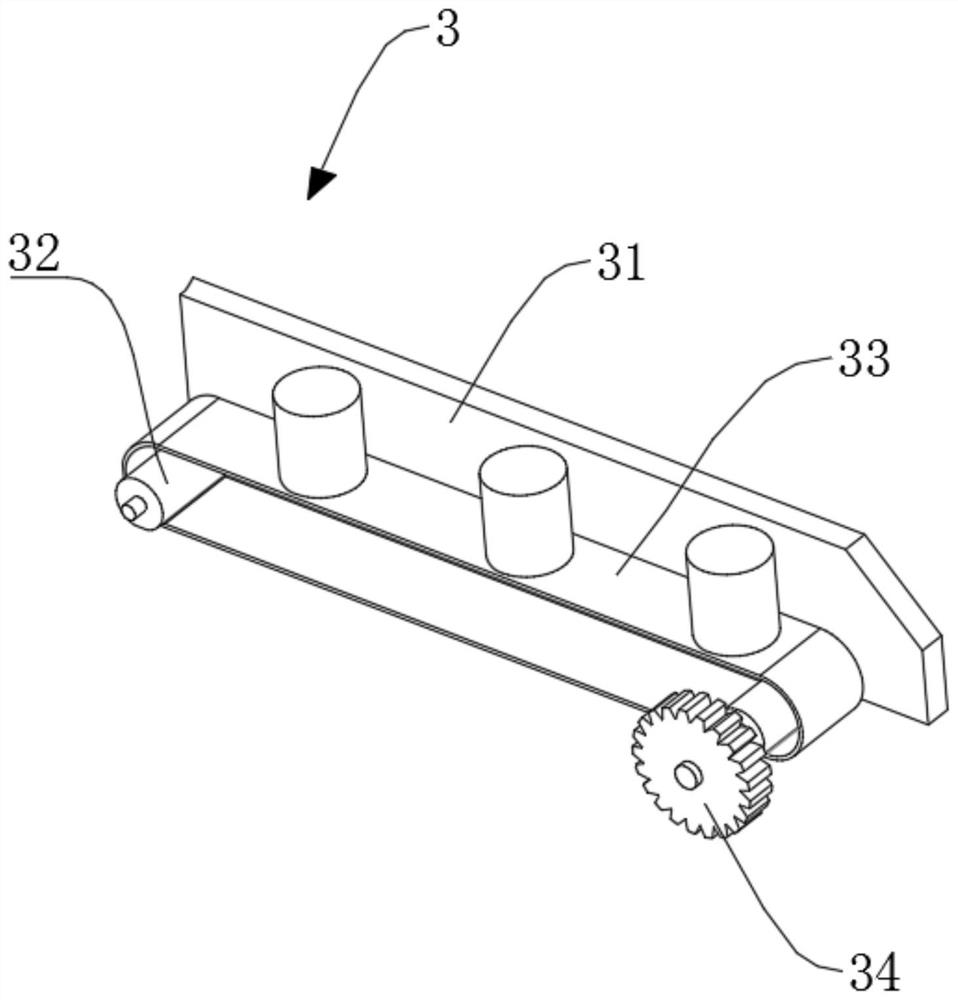

[0028] refer to Figure 1-5 , a casting loading and distributing equipment, comprising a support frame 1, a workbench 2 is fixedly installed on the top of the support frame 1, and a feed mechanism 3 is installed on one end of the workbench 2, and the feed mechanism 3 includes a fixed frame plate 31, two A transmission roller 32, a transmission belt 33 and a transmission gear 34, the fixed frame plate 31 is fixedly installed on the top of the workbench 2, and the two transmission rollers 32 are respectively rotated and installed at the two ends of the fixed frame plate 31 inner side, and the two transmission rollers 32 pass through Conveyor belt 33 transmission connections, wherein the outer end of one conveying roller 32 is coaxially fixedly connected with transmission gear 34, is placed with some corresponding castings 8 on the transmission belt 33, and castings 8 are equidistantly distributed on the transmission belt 33; Through transmission gear 34 The corresponding conveyi...

Embodiment 2

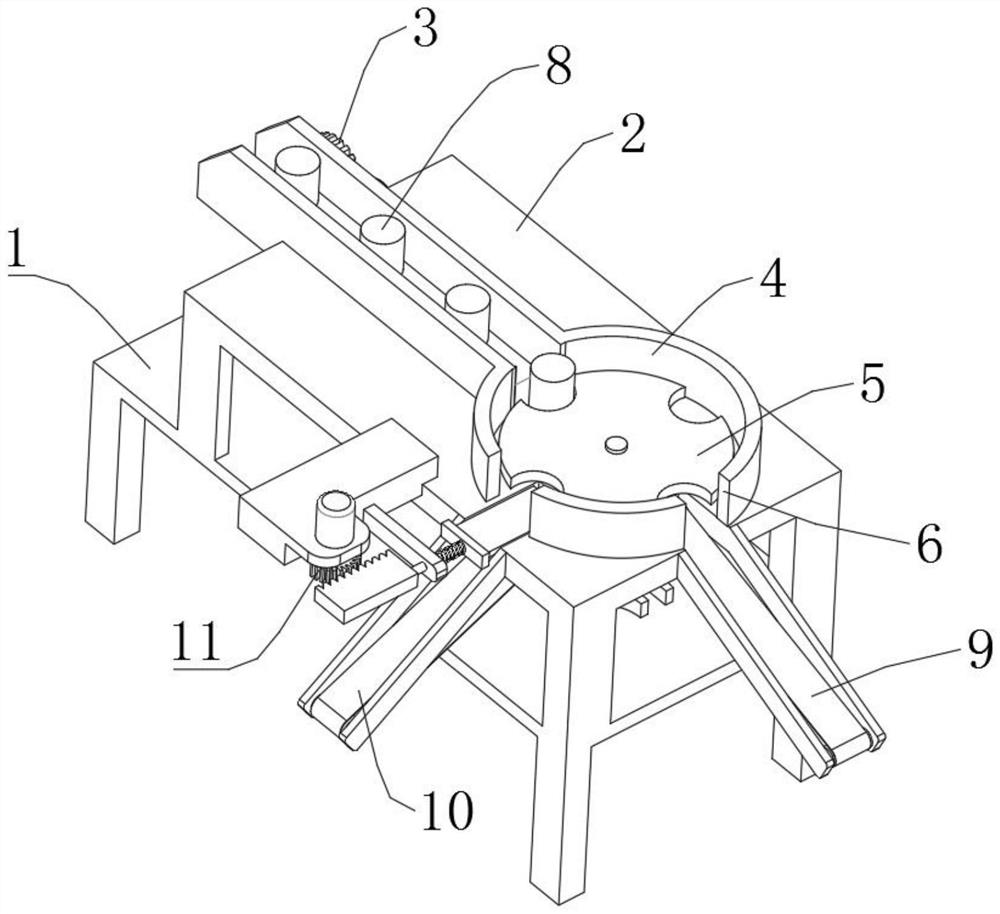

[0035] refer to Figure 1-6 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the bottom end of one of the discharge ports 6 is equipped with a second material distribution mechanism 11, and the second material distribution mechanism 11 includes a fixed seat 111, and the fixed seat 111 is fixedly installed on the top of the workbench 2, and one side of the fixed seat 111 is fixedly equipped with a guide seat 112, and one end of the guide seat 112 is slidably installed with a through slide bar 115, and one end of the slide bar 115 is fixedly installed with a limit plate 114, limiting The side of the position plate 114 away from the slide bar 115 is fixedly equipped with a slide plate 113, the slide plate 113 is located on the inner side of the mounting seat 4, and is slidably connected with the bottom surface of the mounting seat 4, and a return is installed between the limit plate 114 and the guide seat 112. The spring 116 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com