Hydraulic driven built-in rotation scraping type pipeline cleaning device

A hydraulically driven and rotary scraping technology, which is applied in the direction of cleaning hollow objects, cleaning methods and tools, chemical instruments and methods, etc., can solve problems such as single structure of pigging devices, limited operating efficiency, and large cleaning resistance of pigs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

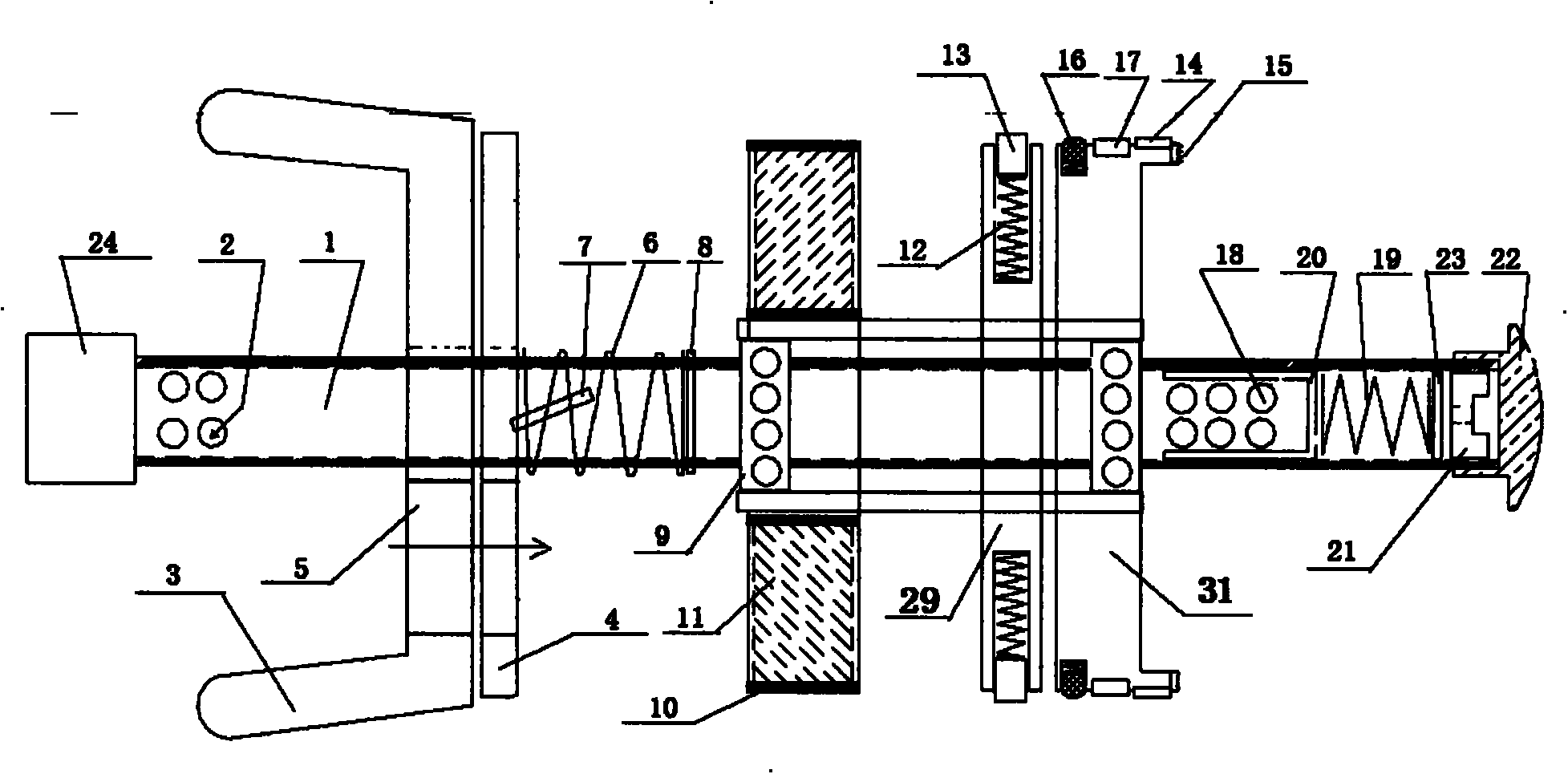

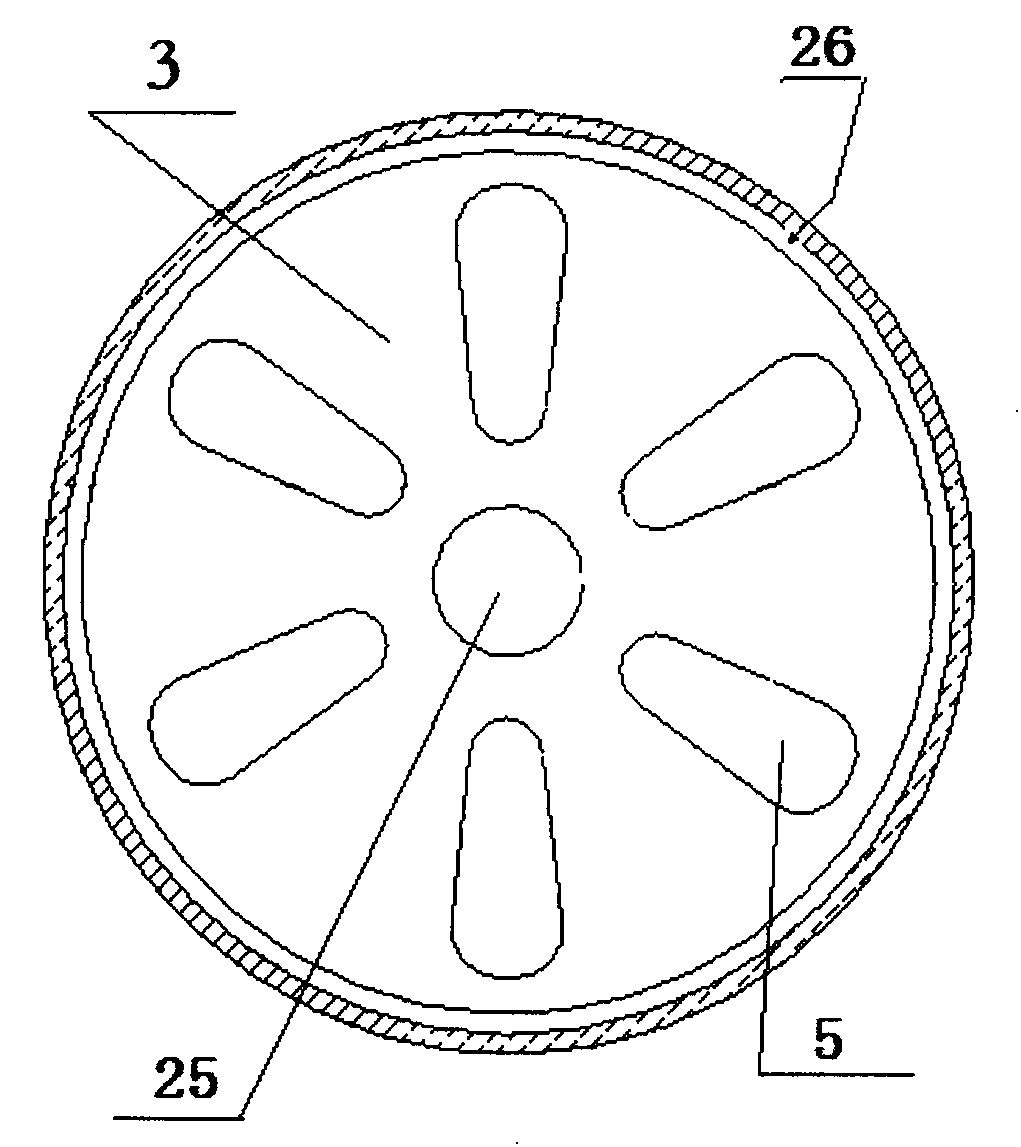

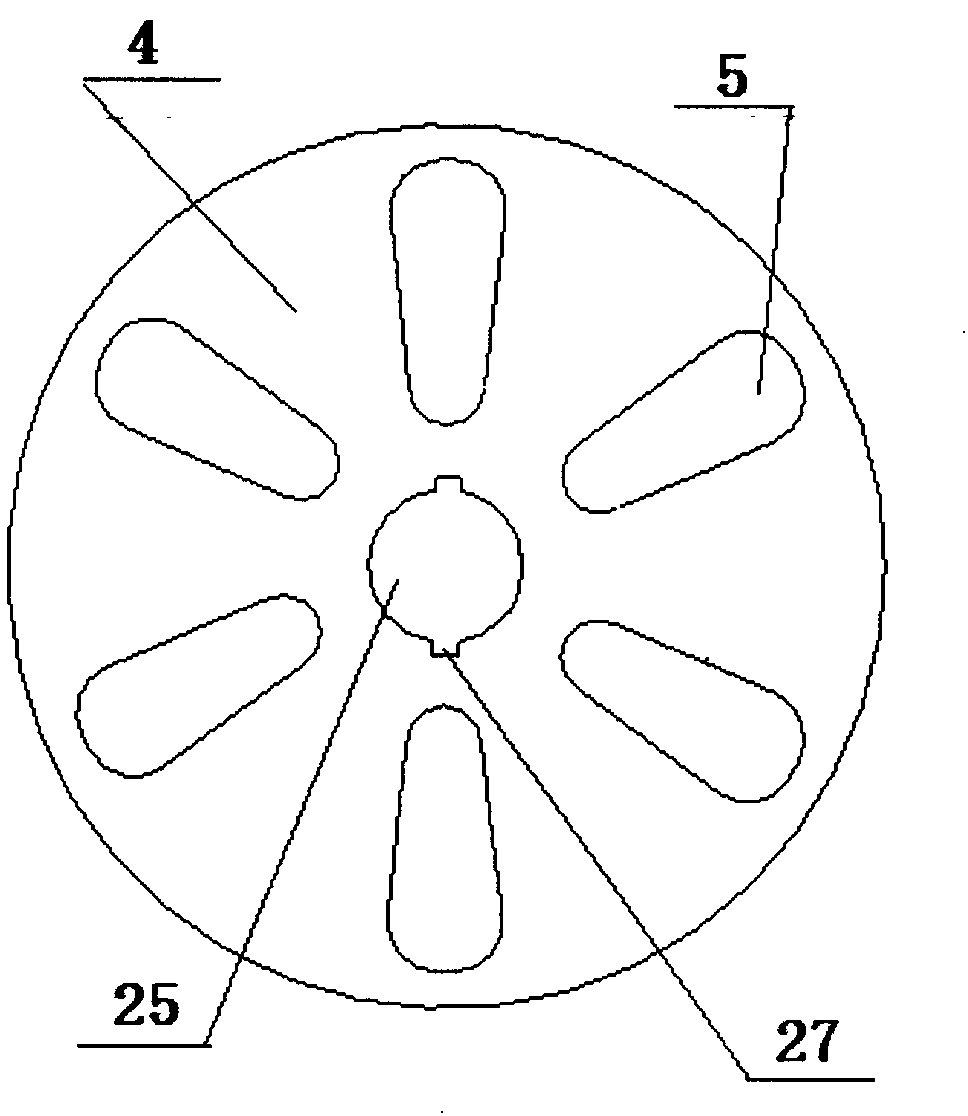

[0027] The present invention includes: main shaft 1, main deflector 3, auxiliary deflector 4, pressure relief hole 5, tapered roller bearing 9, closed impeller 11, fairing 22, blade 28, positioning support frame 29 and composite pigging knife 32.

[0028] as attached figure 1 Shown: the main shaft 1 is connected with the main deflector 3, the auxiliary deflector 4, the tapered roller bearing 9, the closed impeller 11, the positioning support frame 29 and the composite pigging knife 32 sequentially from the back to the front, and the front end of the main shaft 1 is installed Fairing 22, wherein, the main deflector 3 and the auxiliary deflector 4 respectively have a pressure relief hole 5 whose center line is parallel to the axial direction of the main shaft 1, the main deflector 3 is fixedly installed on the main shaft 1, and the auxiliary deflector 4 is slidably insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com