Nutritional biscuit with high bone calcium and making method thereof

A bone calcium and nutrition technology, applied in the field of high bone calcium nutrition biscuit and its production, can solve the problems of poor food flavor and poor palatability, and achieve the effects of unique flavor, improved tissue structure, and improved tissue structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

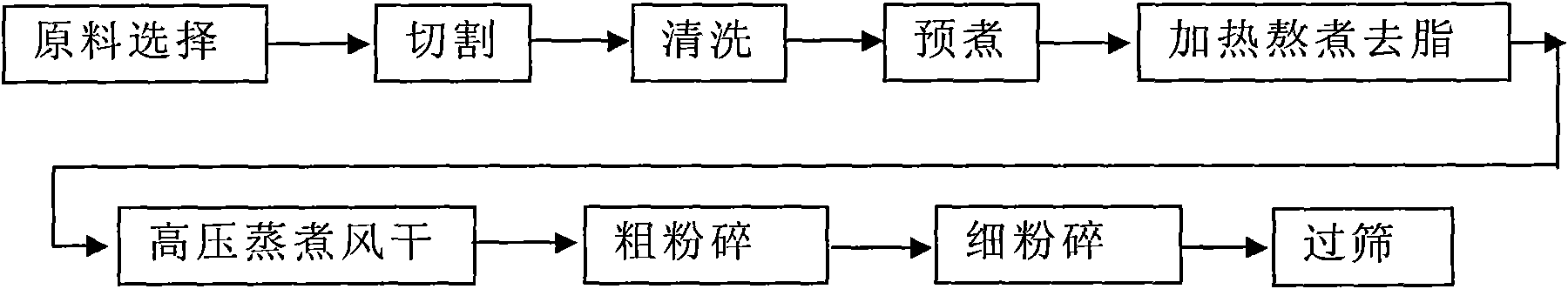

[0041] Three, the preparation of bovine bone meal hydrolyzate:

[0042] Using two proteases to hydrolyze bovine bone powder step by step, hydrolysis conditions: temperature 45°C, initial pH value 8.0, time ratio 1:1, enzyme dosage ratio 1:1, solid-liquid ratio fixed at 1:2, total enzyme dosage 4000U / g bone meal, hydrolyzed for 6h. After hydrolyzing with one protease at 45°C for 3h, another protease was used for further hydrolysis at 45°C for 3h.

[0043] The time ratio referred to here refers to the time ratio of the first step of enzymolysis and the second step of enzymolysis, and the ratio of enzyme dosage refers to the ratio of enzyme dosage of the first step of enzymolysis to the second step of enzymolysis. The bovine bone powder hydrolyzate contains All products after the first and second enzymatic hydrolysis, including non-hydrolyzed bovine bone meal.

Embodiment

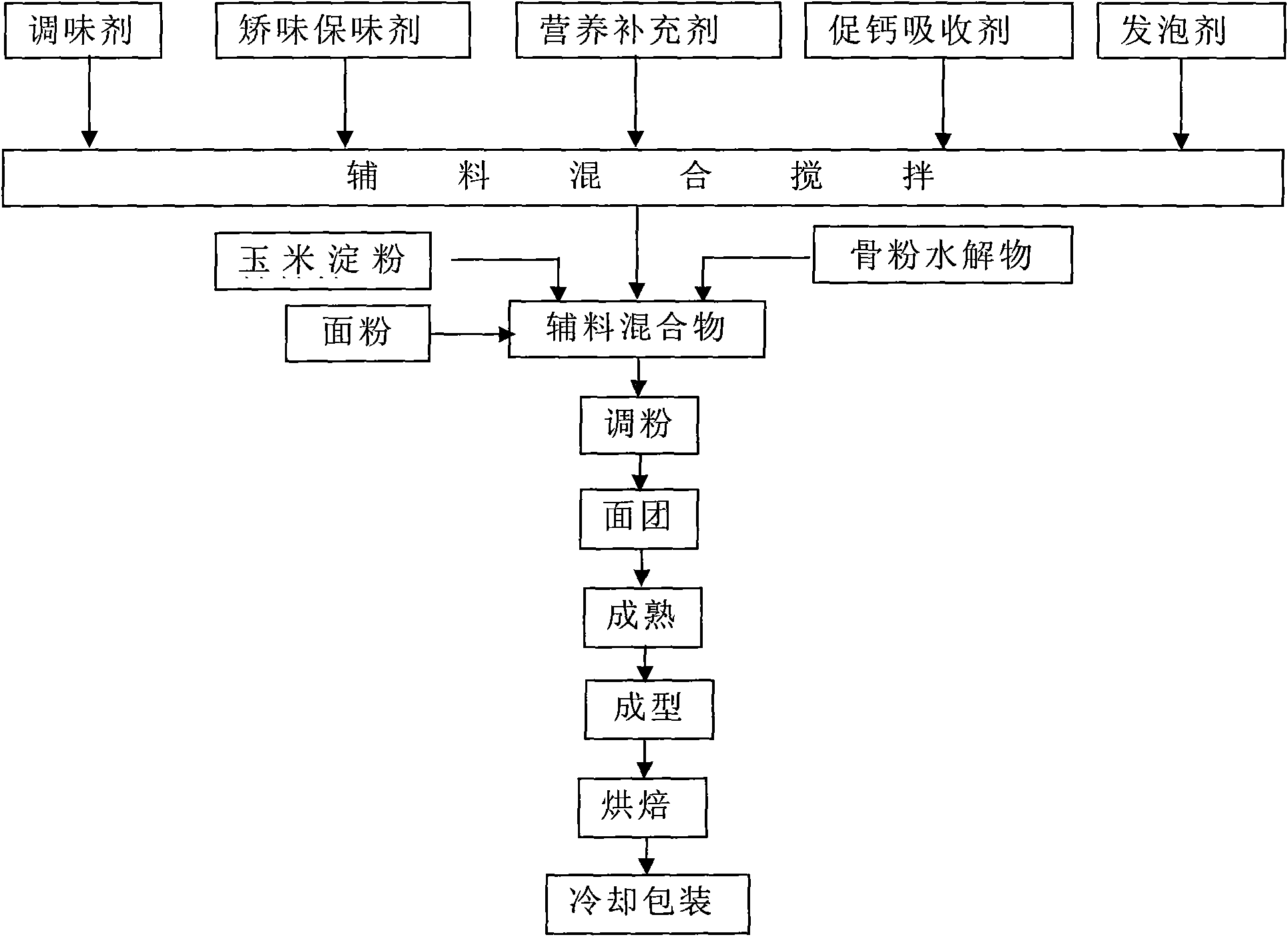

[0044] Embodiments: 1. Prepare bovine bone powder for later use according to the operating points of the bovine bone powder preparation process; 2. Prepare bovine bone powder hydrolyzate for subsequent use according to the preparation method of the hydrolyzate of bovine bone powder. 3. Produce products according to the production points of high bone calcium nutritional biscuits. The process flow and operation points are as follows:

[0045] (1) Mixing of auxiliary materials: 150ml of vegetable oil, 250g of white sugar, 4g of salt, 50g of eggs, 10g of phospholipid, 4g of sodium bicarbonate, 2g of ammonium bicarbonate, 1ml of cream essence, 0.1g of citric acid, 60g of whole milk powder, 80g of lactose, fructo-oligosaccharide 10g, zinc gluconate 15mg, β-cyclodextrin 70mg, ethyl maltol 80mg, casein phosphopeptide (CPP 3 ) 1.4g, V D3 0.015 mg is fully mixed into an auxiliary material mixture for later use;

[0046] (2) Powder adjustment: add 950g of flour and 50g of corn flour to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com