Preparation method for instant longan powder

A production method and technology of instant powder, which are applied to the functions of food ingredients, food ingredients as taste improvers, and food ingredients containing natural extracts, etc., can solve the problems of economic losses, bad taste, and perishability of fruit farmers, and achieve enhanced Coordination, guarantee of taste and flavor, effect of lowering cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

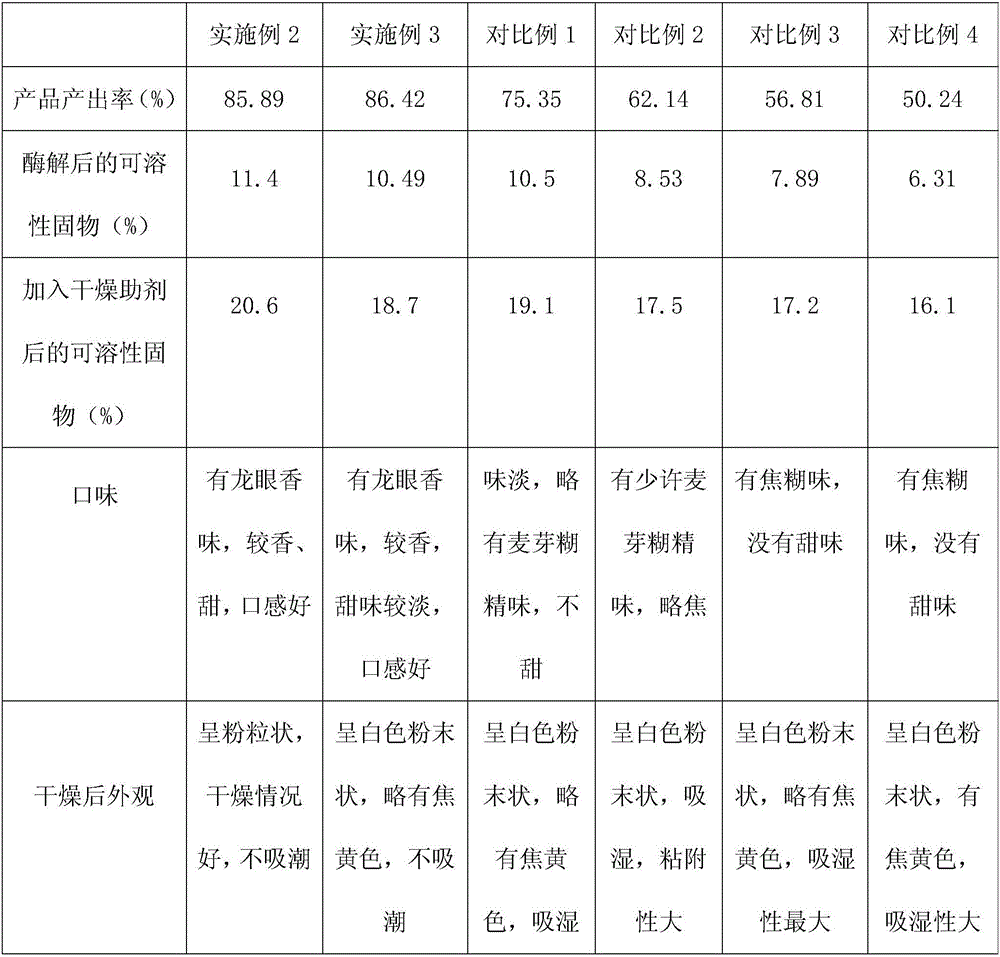

Examples

Embodiment 1

[0038] A kind of preparation method of longan instant powder, specifically comprises the following steps:

[0039] (1) Raw materials: select longan with yellowish-brown skin and full shell, wash it with water, remove the longan shell and core, and keep the longan pulp;

[0040] (2) Juicing: get 10kg of longan pulp described in step (1), mix it with 50kg of deionized water, then put it into a juice extractor and squeeze, cross a 20-mesh sieve to obtain longan juice;

[0041] (3) Enzymolysis: Add mixed enzymes to the longan juice described in step (2) by using the compound enzymatic hydrolysis method, then enzymolyze at 45°C for 2.5 hours, then put it in a water bath at 90°C for 5 minutes, filter and retain the filtrate Wherein, described mixed enzyme is pectinase and cellulase, and the mass ratio of described pectinase and cellulase is 1:1.1; Wherein, described pectinase is made of protopectinase, pectin A Ester hydrolase and pectinase are mixed according to the mass ratio of 3:...

Embodiment 2

[0047] A kind of preparation method of longan instant powder, specifically comprises the following steps:

[0048] (1) Raw materials: select longan with yellowish-brown skin and full shell, wash it with water, remove the longan shell and core, and keep the longan pulp;

[0049] (2) Juicing: get 10kg of longan pulp described in step (1), mix it with 50kg of deionized water, then put it into a juice extractor and squeeze, cross a 20-mesh sieve to obtain longan juice;

[0050] (3) Enzymolysis: Add mixed enzymes to the longan juice described in step (2) by using the compound enzymatic hydrolysis method, then enzymolyze at 45°C for 2.5 hours, then put it in a water bath at 90°C for 5 minutes, filter and retain the filtrate Wherein, described mixed enzyme is pectinase and cellulase, and the mass ratio of described pectinase and cellulase is 1:1.1; Wherein, described pectinase is made of protopectinase, pectin A Ester hydrolase and pectinase are mixed according to the mass ratio of ...

Embodiment 3

[0056] A kind of preparation method of longan instant powder, specifically comprises the following steps:

[0057] (1) Raw materials: select longan with yellowish-brown skin and full shell, wash it with water, remove the longan shell and core, and keep the longan pulp;

[0058] (2) Juicing: get 10kg of longan pulp described in step (1), mix it with 50kg of deionized water, then put it into a juice extractor and squeeze, cross a 20-mesh sieve to obtain longan juice;

[0059] (3) Enzymolysis: Add mixed enzymes to the longan juice described in step (2) by using the compound enzymatic hydrolysis method, then enzymolyze at 45°C for 2.5 hours, then put it in a water bath at 90°C for 5 minutes, filter and retain the filtrate Wherein, described mixed enzyme is pectinase and cellulase, and the mass ratio of described pectinase and cellulase is 1:1.1; Wherein, described pectinase is made of protopectinase, pectin A Ester hydrolase and pectinase are mixed according to the mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com